Preparation and application of biomass carbon coated cobalt sulfide-cobalt octasulfide composite material

A technology of composite materials and biomass carbon, applied in the direction of active material electrodes, electrochemical generators, electrical components, etc., can solve problems such as difficult to achieve high rate performance, slowness, and weakened power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

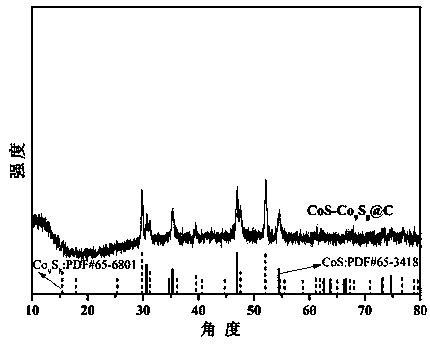

[0024] Disperse 0.8 g of cobalt chloride hexahydrate and 2.0 g of thioacetamide in 50 mL of distilled water, then add 2.0 g of gum arabic to the above solution and stir vigorously until the solution is clear, then place it in polytetrafluoroethylene Lined with a stainless steel reactor, reacted at 200°C for 12 h, cooled to room temperature, washed with deionized water and ethanol, and dried in an oven at 80°C to obtain the precursor product; then the precursor product was placed in a quartz tube protected by a nitrogen atmosphere , heat-treated at 600 °C for 2 h to obtain the product CoS-Co 9 S 8 @C.

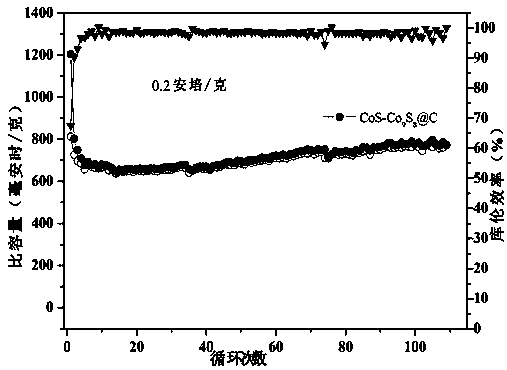

[0025] CoS-Co 9 S 8 When @C is used as the anode of lithium-ion batteries, the reversible specific capacity reaches 784.9 mAh g for the first time -1 , with a reversible specific capacity of 754.6 mAh g after 100 cycles -1 , the capacity retention rate is 96.1%; CoS-Co 9 S 8 When @C is used as the anode of Na-ion batteries, the reversible specific capacity reaches 678.4 m...

Embodiment 2

[0027] Disperse 0.8 g of cobalt sulfate and 2.0 g of thioacetamide in 50 mL of distilled water, then add 2.0 g of gum arabic to the above solution and stir vigorously until the solution is clear, then place it in a polytetrafluoroethylene liner The stainless steel reaction kettle was reacted at 200 °C for 12 h, cooled to room temperature, washed with deionized water and ethanol, and dried in an oven at 80 °C to obtain the precursor product; then the precursor product was placed in a nitrogen atmosphere protected quartz tube, at 600 °C After heat treatment for 2 h, the product CoS-Co 9 S 8@C.

[0028] CoS-Co 9 S 8 When @C is used as the anode of lithium-ion batteries, the reversible specific capacity reaches 679.4 mAh g for the first time -1 , with a reversible specific capacity of 589.8 mAh g after 100 cycles -1 , the capacity retention rate was 86.8%; CoS-Co 9 S 8 When @C is used as the anode of Na-ion batteries, the reversible specific capacity reaches 554.4 mAh g for...

Embodiment 3

[0030] Disperse 0.8 g of cobalt acetate and 2.0 g of thioacetamide in 50 mL of distilled water, then add 2.0 g of gum arabic to the above solution and stir vigorously until the solution is clear, then place it in a polytetrafluoroethylene liner The stainless steel reaction kettle was reacted at 200 °C for 12 h, cooled to room temperature, washed with deionized water and ethanol, and dried in an oven at 80 °C to obtain the precursor product; then the precursor product was placed in a nitrogen atmosphere protected quartz tube, at 600 °C Under heat treatment for 2h, the product CoS-Co was obtained 9 S 8 @C.

[0031] CoS-Co 9 S 8 When @C is used as the anode of lithium-ion batteries, the reversible specific capacity reaches 856.7 mAh g for the first time -1 , with a reversible specific capacity of 833.5 mAh g after 100 cycles -1 , the capacity retention rate is 97.3%; CoS-Co 9 S 8 When @C is used as the anode of Na-ion batteries, the reversible specific capacity reaches 712...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com