Method for modification of plantation wood by inorganic impregnation

A technology for plantation and wood, applied in the direction of impregnation of wood, wood treatment, wood heating, etc., can solve the problems of increasing modification cost, release, loose material, etc., and achieve the effect of improving impregnation efficiency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

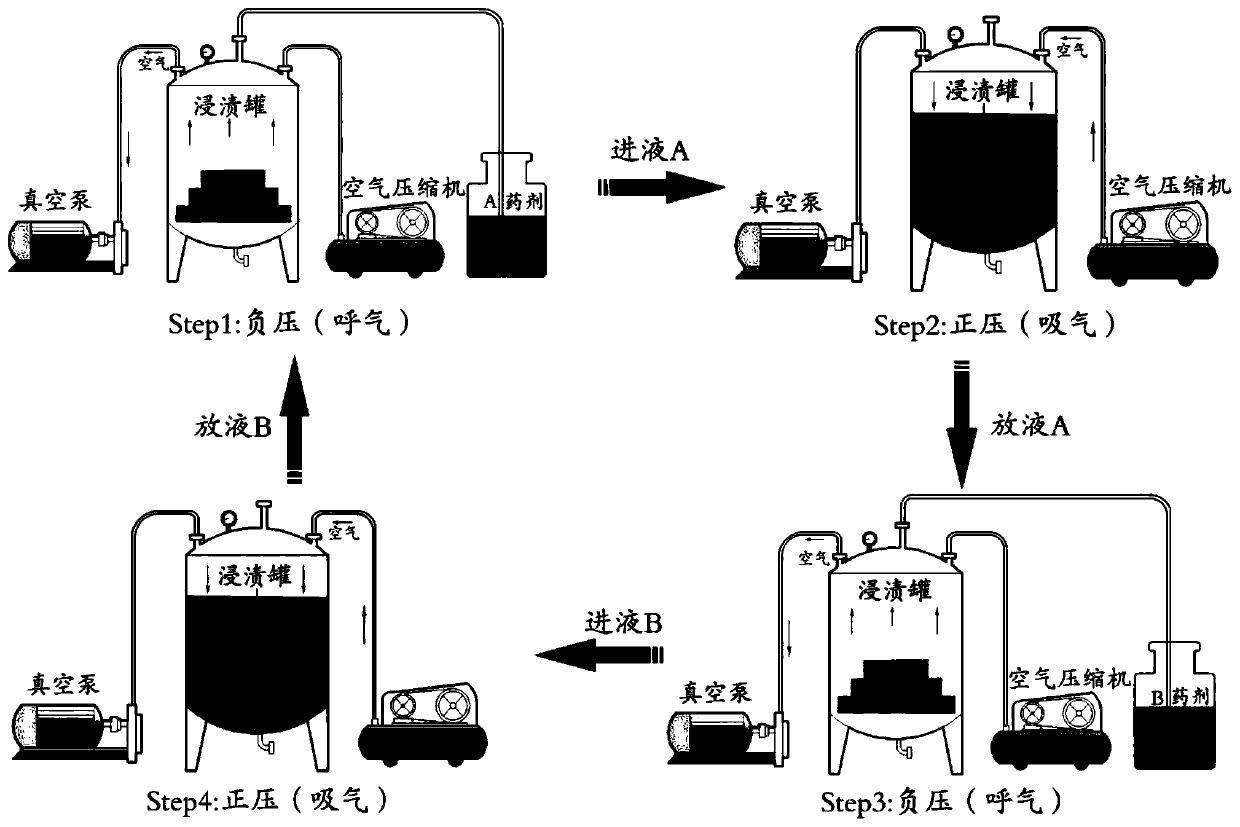

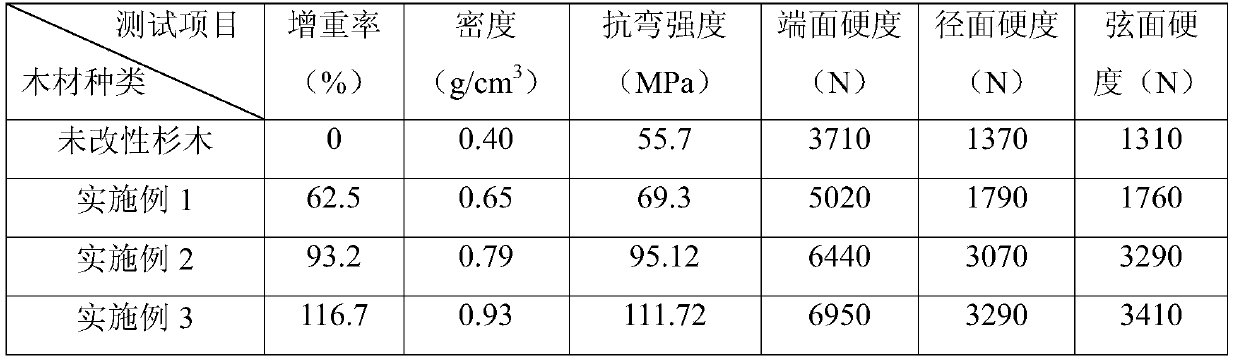

[0029] A method of inorganic impregnation and modification of plantation wood, such as figure 1 As shown, including the following steps:

[0030] (1) Saw the cedar wood into a size of 10mm×10mm×200mm, and dry it to a moisture content of 12%. Prepare 284.2 parts by weight of sodium silicate solution, the mass fraction of sodium silicate solution is 10%, and it will be used as A solution. Dissolve 2.84 parts by weight of polyvinyl alcohol in 53.96 parts by weight of water in a 95°C water bath to prepare a 5% by weight aqueous solution of polyvinyl alcohol, then mix 12.02 parts by weight of silica, 0.4 parts by weight of magnesium oxide modifier, and 0.81 parts by weight of polyvinyl alcohol Part by weight of zinc oxide is mixed evenly with the prepared polyvinyl alcohol aqueous solution, prepared into B solution, and set aside. One part by weight can be 1g, 1kg, etc. Put the cedar wood with a moisture content of 12% after drying treatment into the impregnation tank, vacuumize th...

Embodiment 2

[0034] A method of inorganic impregnation and modification of plantation wood, such as figure 1 As shown, including the following steps:

[0035] (1) The plantation fir wood is sawn into a size of 20mm×20mm×400mm, and dried to a moisture content of 10%. Prepare 284.2 parts by weight of a 30 wt% sodium silicate solution as A solution. Dissolve 8.52 parts by weight of polyvinyl alcohol in 275.48 parts by weight of water in a 95°C water bath to prepare a 3% aqueous solution of polyvinyl alcohol, and then mix 5.1 parts by weight of aluminum oxide and 7.05 parts by weight of aluminum silicate with The aqueous solution of polyvinyl alcohol is mixed evenly, prepared into liquid B, and set aside. In this embodiment, 1 part by weight may be 1 g or 1 kg. Put the dried cedar wood with 10% moisture content into the impregnation tank, evacuate the impregnation tank to -0.095MPa, keep the pressure for 20 minutes, and then start to enter the liquid, and use the negative pressure in the tank ...

Embodiment 3

[0039] A method of inorganic impregnation modified plantation wood, such as figure 1 As shown, including the following steps:

[0040] (1) The plantation fir wood is sawed into a size of 40mm×40mm×800mm, and dried to a moisture content of 8%. Prepare 284.2 parts by weight of a 40 wt% sodium silicate solution as A solution. Dissolve 14.21 parts by weight of polyvinyl alcohol in 1406.79 parts by weight of water in a 95°C water bath to prepare a 1% polyvinyl alcohol aqueous solution, and then mix 3 parts by weight of silica, 4.03 parts by weight of magnesium oxide modifier, and 1.02 parts by weight. Parts by weight of aluminum oxide, 0.81 parts by weight of zinc oxide, and 14.11 parts by weight of aluminum silicate are uniformly mixed with the prepared polyvinyl alcohol aqueous solution, and prepared into liquid B, ready for use. In this embodiment, 1 part by weight may be 1 g or 1 kg. Put the dried cedar wood with 8% moisture content into the impregnation tank, evacuate the impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com