Sensitive electrode for direct electrochemical detection of ammonia nitrogen in water and preparation method of sensitive electrode

A sensitive electrode and electrochemical technology, applied in the field of electrochemical sensing, can solve the problems of inability to appear oxidation peaks, cumbersome process, high ammonia oxidation potential, etc., and achieve complex detection process, uniform particle size, and high anti-interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

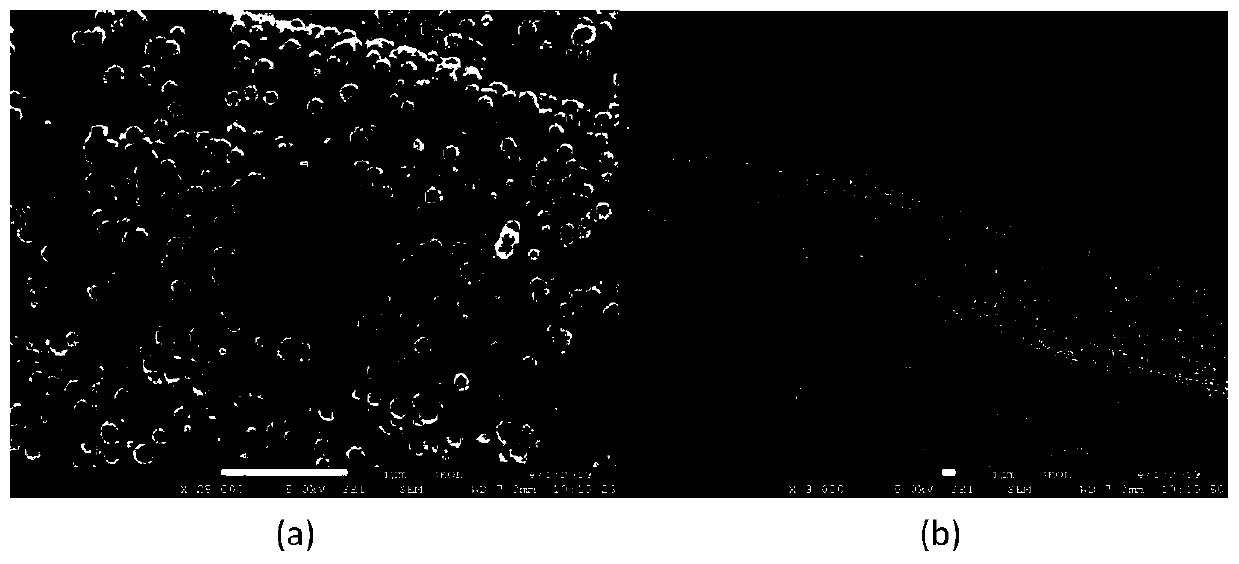

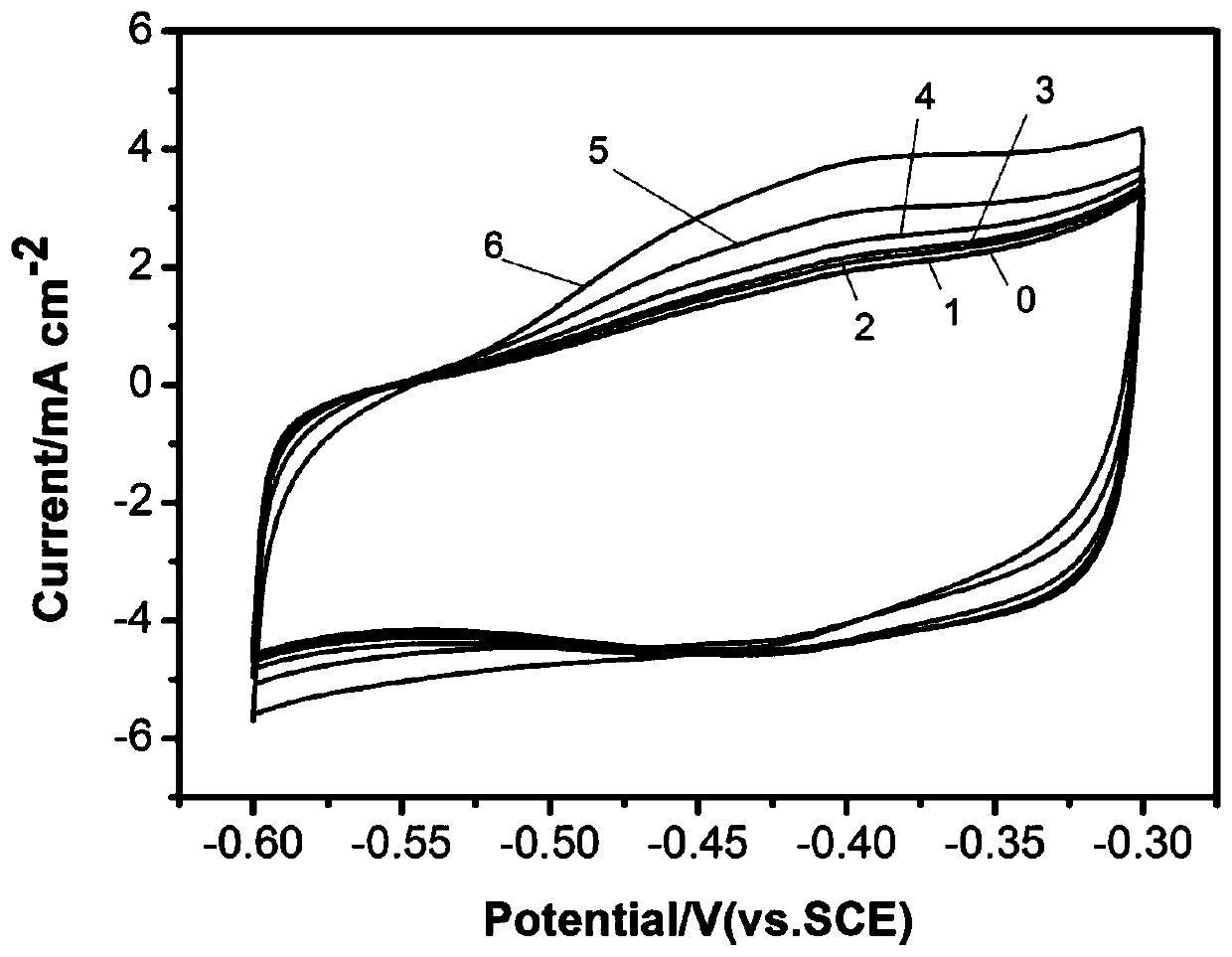

[0033] The preparation method of the sensitive material suitable for direct electrochemical ammonia nitrogen detection in water body is as follows:

[0034] a) Cut the carbon cloth into 0.5cm×1cm, ultrasonically clean it with toluene, acetone, ethanol, deionized water, and hydrochloric acid for 10 minutes, and finally clean it with deionized water for use;

[0035] b) Prepare 3.5mM H 2 PtCl 4 and 0.5mM NiSO 4 The mixed aqueous solution is used as the electrolyte;

[0036] c) Electrochemical deposition is carried out using a three-electrode system. The carbon cloth obtained in step a) is used as the working electrode, the platinum sheet electrode is used as the counter electrode, and the Ag / AgCl electrode is used as the reference electrode. Cyclic voltammetry is used, and the potential interval is -0.8 ~0.6V, the number of scanning cycles is 15, and the scanning speed is 10mv / s to obtain the Pt-Ni / carbon cloth electrode material. Dry in a 40°C oven for 2 hours.

[0037] d)...

Embodiment 2

[0039] A) the cleaning process of carbon cloth is as embodiment 1;

[0040] b) other conditions remain unchanged, 3mM H 2 PtCl 4 and 1mM NiSO 4 mixed aqueous solution as electrolyte;

[0041] c) Electrochemical deposition was carried out using a three-electrode system, with carbon cloth as the working electrode, platinum sheet electrode as the counter electrode, and Ag / AgCl electrode as the reference electrode. Cyclic voltammetry was used with the potential range of -0.8 to 0.6V. The number of laps is 15 laps, and the scanning speed is 10mv / s to obtain the Pt-Ni / carbon cloth electrode material, and the electrode is placed in a 40°C oven to dry for 2 hours before use.

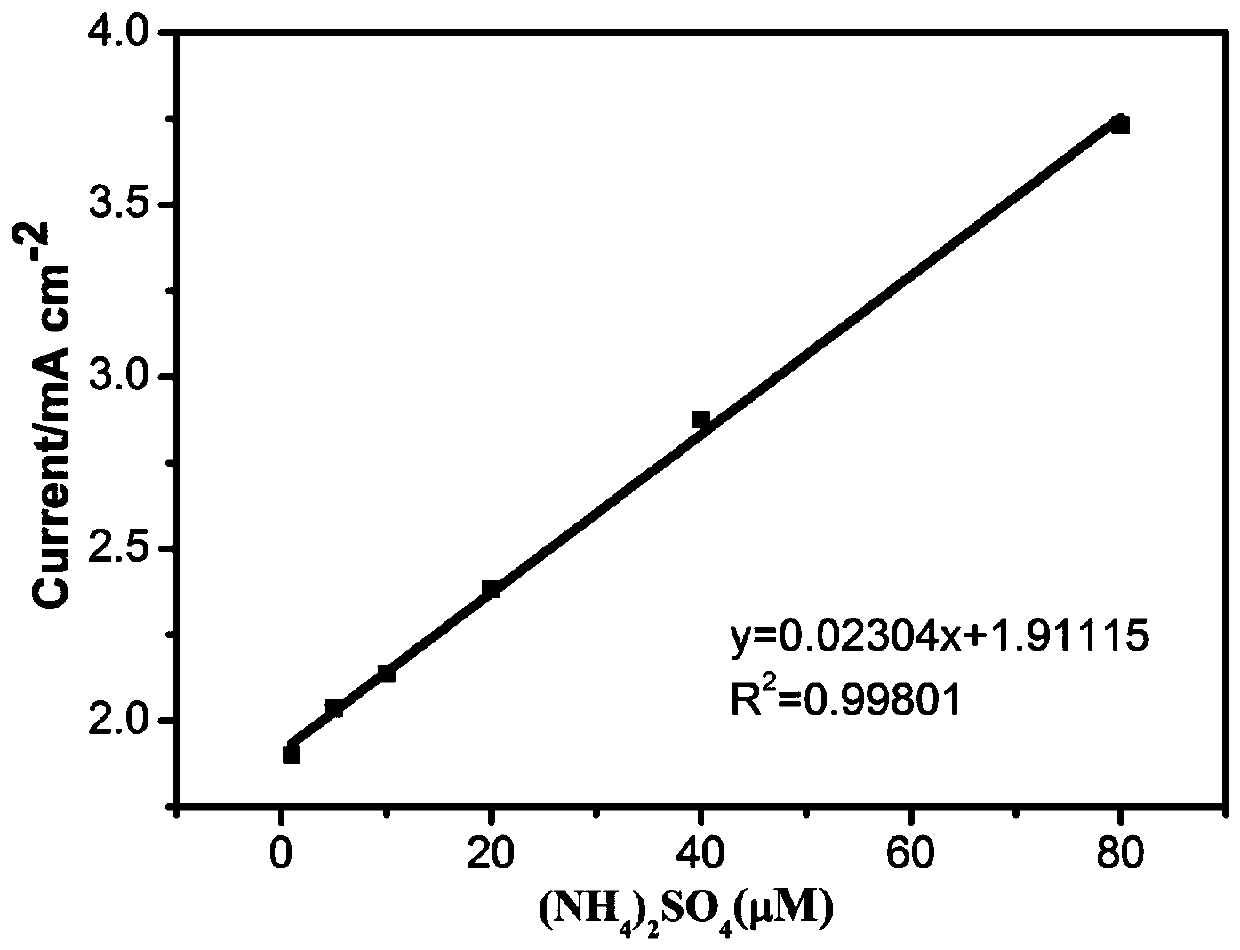

[0042]d) The test process is the same as in Example 1, and the test results show that the sensitivity of the electrode prepared by the inventive method to ammonia nitrogen detection is 11.435mA cm -2 mM -1 .

Embodiment 3

[0044] A) the cleaning process of carbon cloth is as embodiment 1;

[0045] b) Other conditions remain unchanged, 2.5mM H 2 PtCl 4 and 1.5mM NiSO 4 mixed aqueous solution as electrolyte;

[0046] c) A three-electrode system is used for electrochemical deposition, with carbon cloth as the working electrode, platinum sheet electrode as the counter electrode, and Ag / AgCl electrode as the reference electrode. Cyclic voltammetry is used with the potential range of -0.8 to 0.6, and the scanning circle The number is 15 cycles, and the sweep speed is 10mv / s to obtain the Pt-Ni / carbon cloth electrode material, and the electrode is placed in a 40°C oven to dry for 2 hours before use.

[0047] d) The test process is the same as in Example 1, and the test results show that the sensitivity of the electrode prepared by the method of the present invention to the detection of ammonia nitrogen is 12.72mA cm -2 mM -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com