sio 2 /pvdf-hfp composite fiber membrane and its preparation method and application

A technology of PVDF-HFP and composite fiber membrane, which is applied in the field of electrochemistry, can solve problems such as limitations, low mechanical strength, and major safety issues, and achieve the effects of high mechanical strength, improved battery performance, and high porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

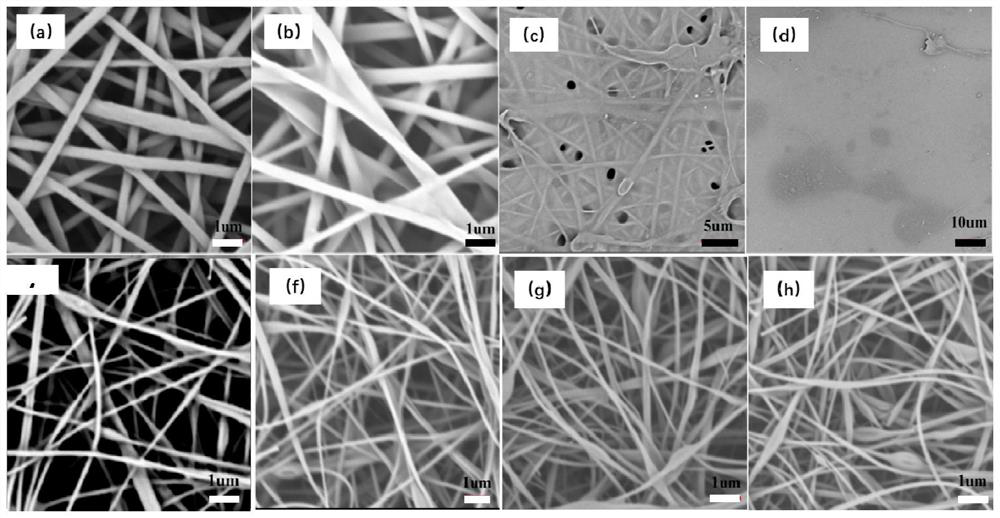

[0040] The embodiment of the present invention provides a SiO 2 The preparation method of / PVDF-HFP composite fiber membrane comprises the following steps:

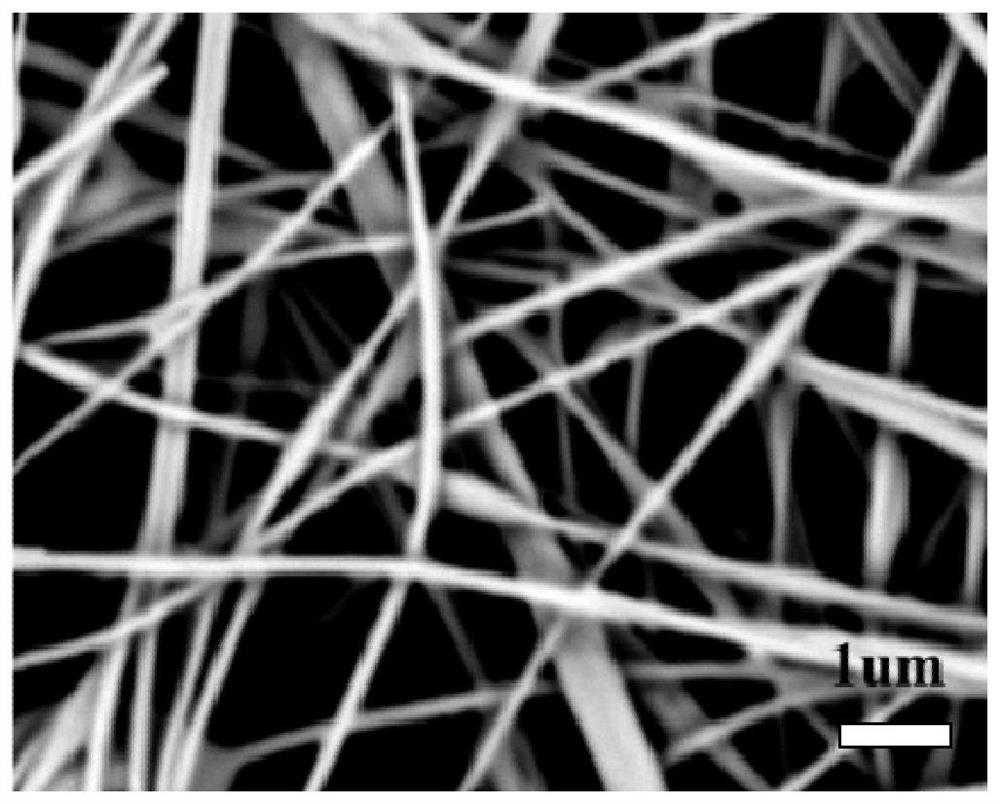

[0041] Preparation of PVDF-HFP nanofiber membrane: Prepare PVDF-HFP (polyvinylidene fluoride-hexafluoropropylene) spinning precursor solution, inject PVDF-HFP spinning precursor solution into the electrospinning device, and use electrospinning method to obtain PVDF- HFP nanofiber membrane;

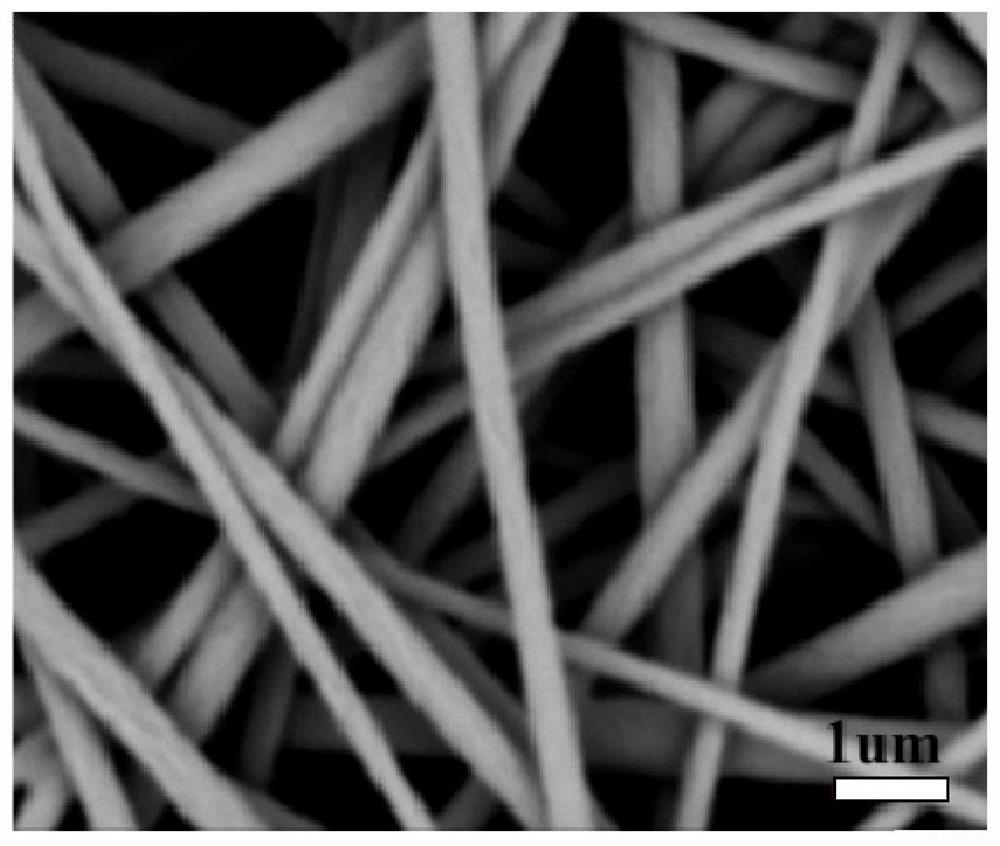

[0042] Preparation of SiO 2 Fiber membrane: dissolving soluble silicon salt and inorganic acid in solvent to obtain SiO 2 (Silicon dioxide) precursor solution, prepare the template polymer solution, the SiO 2 Precursor solution and template polymer solution are mixed to form hybrid SiO 2 Spinning precursor solution, the hybrid SiO 2 The spinning precursor liquid is injected into the electrospinning device, and hybrid SiO is prepared by electrospinning 2 Nanofibrous membranes, on the resulting hybrid SiO 2 Nanofibrous membranes w...

Embodiment 1

[0059] A SiO 2 The preparation method of / PVDF-HFP composite fiber membrane comprises the following steps:

[0060] Preparation of PVDF-HFP spinning precursor solution: Add PVDF-HFP to acetone and DMF (N,N-dimethylformamide) mixed solvent, stir in a water bath heating environment at 40°C until PVDF-HFP is completely dissolved to obtain PVDF- HFP spinning precursor, the content of PVDF-HFP in the PVDF-HFP spinning precursor is 18wt%, and the mass ratio of acetone and DMF in the mixed solvent is 1: 1;

[0061]Electrospinning PVDF-HFP nanofiber membrane: inject PVDF-HFP spinning precursor liquid into the liquid storage mechanism in the electrospinning device, open the electrospinning device, and deposit PVDF-HFP nanofiber membrane on the drum collector , the PVDF-HFP nanofiber membrane was removed from the drum collector; the spinning parameters of the electrospinning process were spinning distance 16cm, spinning voltage 16kV, the propulsion rate of the propulsion pump was 27μL / m...

Embodiment 2

[0079] A SiO 2 The preparation method of / PVDF-HFP composite fiber membrane comprises the following steps:

[0080] Preparation of PVDF-HFP spinning precursor solution: Add PVDF-HFP to a mixed solvent of acetone and DMF (N,N-dimethylformamide), stir in a water bath heating environment at 50°C until PVDF-HFP is completely dissolved to obtain PVDF- HFP spinning precursor, the content of PVDF-HFP in the PVDF-HFP spinning precursor is 22wt%, and the mass ratio of acetone and DMF in the mixed solvent is 1: 1;

[0081] Electrospinning PVDF-HFP nanofiber membrane: inject PVDF-HFP spinning precursor liquid into the liquid storage mechanism in the electrospinning device, open the electrospinning device, and deposit PVDF-HFP nanofiber membrane on the drum collector , the PVDF-HFP nanofiber membrane was removed from the drum collector; the spinning parameters of the electrospinning process were spinning distance 20cm, spinning voltage 22kV, the propulsion rate of the propulsion pump was ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| mechanical strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com