Selenized konjac oligo-glucomannan and preparation and application thereof

A technology of glucomandioligosaccharides and glucomanoligosaccharides, which is applied in the field of selenized konjac glucomanoligosaccharides, can solve the problems of no selenized konjac glucomanoligosaccharides, etc., and achieve anti-aging health food, high selenium content, inhibition The effect of cancer care drugs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 selenized konjac glucomannan oligosaccharides

[0030] Add 0.5g of konjac glucomannan oligosaccharide to 50mL of 0.5% nitric acid aqueous solution, stir to dissolve; add 0.61g of sodium selenite, 0.86g of barium chloride, stir to dissolve; react the solution at 70°C for 9 hours; add 0.5 g sodium sulfate, centrifuged at 8000rpm to remove the precipitate; the supernatant was neutralized to neutral with sodium bicarbonate; 5 times the volume of ethanol was added to the reaction solution to produce a large amount of white precipitate; the solid was obtained by suction filtration, and dried at 60°C in a vacuum desiccator. The white powder selenized konjac glucomannan oligosaccharide was obtained.

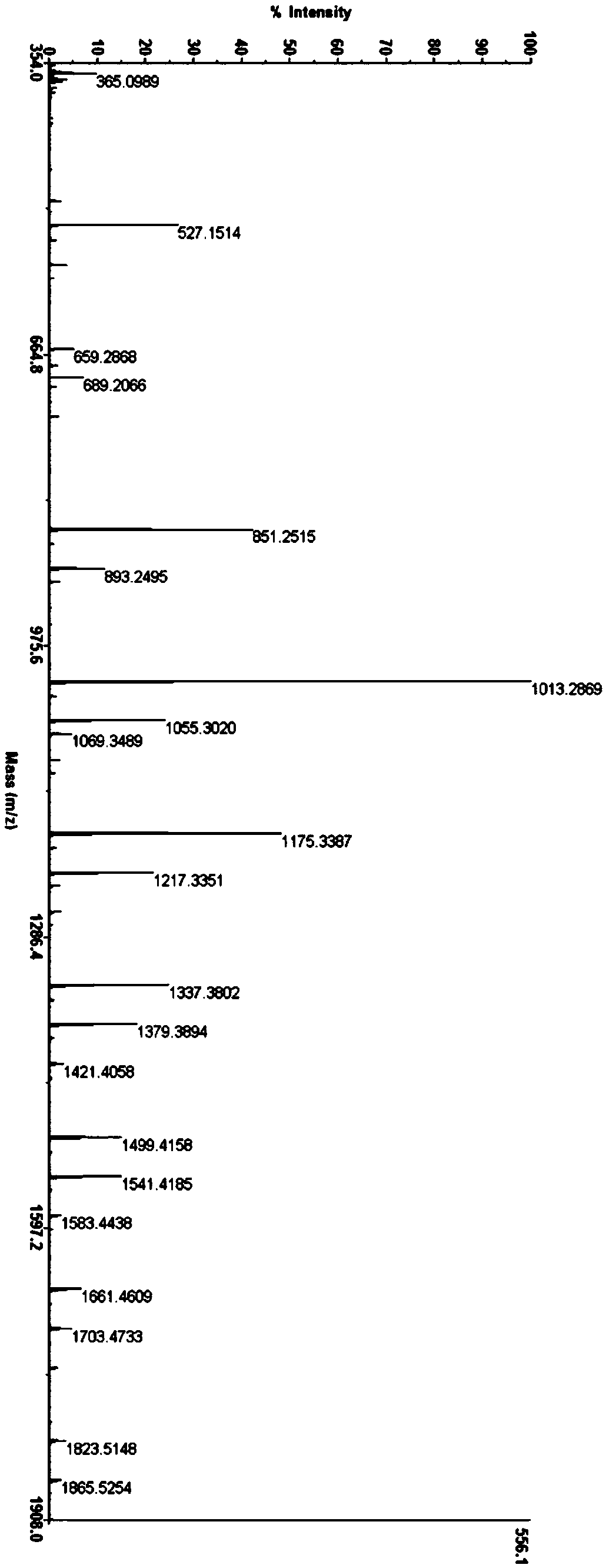

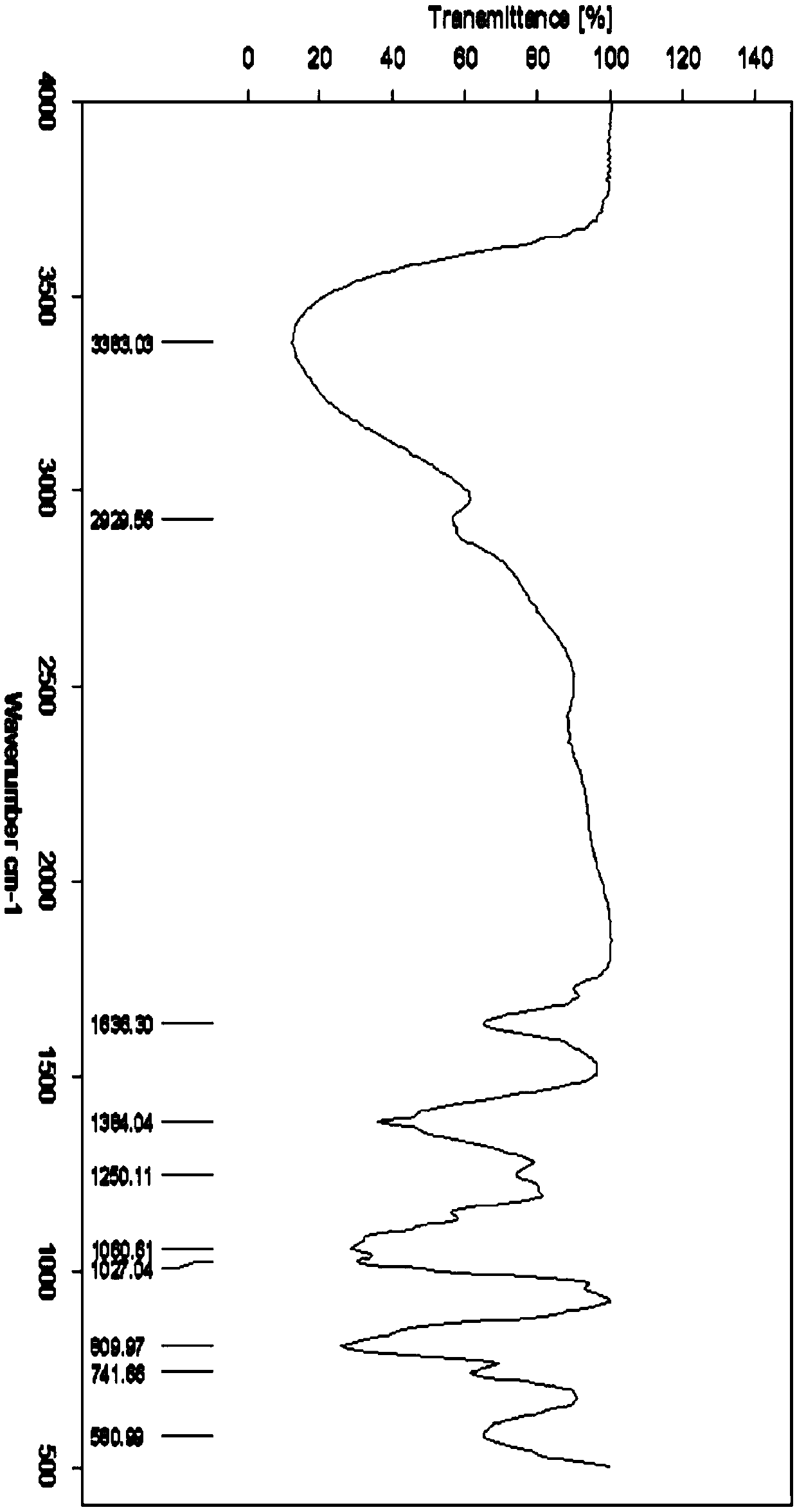

[0031] The selenized konjac glucomannan oligosaccharide is carried out infrared spectrum analysis (see attached figure 2 ), at 740cm -1 There is an obvious absorption peak at the place, which is the absorption peak of selenite, indicating that a ...

Embodiment 2

[0032] The preparation of embodiment 2 selenized konjac glucomannan oligosaccharides

[0033] Get the konjac glucomannan oligosaccharide of 0.5g embodiment 1 and join in the 0.5% phosphoric acid aqueous solution of 50mL, stir to dissolve; Add 0.81g sodium selenite, 0.86g barium chloride, stir to dissolve; The solution is reacted at 80 ℃ 6 Add 0.5g of potassium sulfate, 8000rpm centrifuge to remove the precipitate; the supernatant is neutralized to neutral with sodium carbonate; 6 times the volume of ethanol is added to the reaction solution to produce a large amount of white precipitate; the solid is obtained by suction filtration, and the 40 ℃ drying to obtain white powder selenized konjac glucomannan oligosaccharide.

[0034] Carry out infrared spectroscopic analysis to selenized konjac glucomannan oligosaccharide, at 740cm -1 There is an obvious absorption peak at the place, which is the absorption peak of selenite, indicating that a selenization reaction has taken place o...

Embodiment 3

[0035] The preparation of embodiment 3 selenized konjac glucomannan oligosaccharides

[0036] Take 0.5g of the konjac glucomannan oligosaccharide of Example 1 and add it to 50mL of 1.0% hydrochloric acid aqueous solution, stir and dissolve; add 0.821g sodium selenate, 0.91g calcium chloride, stir and dissolve; react the solution at 60°C for 10 hours ; Add 0.5g of potassium sulfate, 8000rpm centrifugation to remove the precipitate; the supernatant is neutralized to neutral with sodium hydroxide; 3 times the volume of ethanol is added to the reaction solution to produce a large amount of white precipitate; the solid is obtained by suction filtration, and the 60 ℃ drying to obtain white powder selenized konjac glucomannan oligosaccharide.

[0037] Carry out infrared spectrum analysis to selenized konjac glucomannan oligosaccharide, at 741cm -1 There is an obvious absorption peak at the place, which is the absorption peak of selenite, indicating that a selenization reaction has t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com