Non-additive natural fructus momordicae syrup and preparation method and application thereof

A Luo Han Guo, additive-free technology, applied in the direction of fructose production, purification using physical methods, application, etc., can solve the problems of complicated process steps, impact on extraction efficiency, and influence on the taste and flavor of the concentrated liquid, and achieve the effect of pure and sweet taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The raw material is the adsorption resin waste water from the production process of fresh Luo Han Guo.

[0074] 1. Tertiary membrane separation refining and concentration.

[0075] (1) Pump 10,000L of adsorption resin wastewater from the production process of fresh Luo Han Guo into the ultrafiltration membrane complete system, select the ultrafiltration membrane molecular weight cut-off as 2KD, control the pressure at 1.5MPa, and collect the liquid downstream of the membrane. After feeding the feed, dilute the upstream liquid twice with 600L purified water, and continue to pass through the membrane to obtain 10-300L ultrafiltration membrane refined liquid.

[0076] (2) Pump the ultrafiltration membrane refined solution into the nanofiltration membrane complete system, select the nanofiltration membrane molecular weight cut-off as 800, control the pressure at 2.5MPa, and collect the downstream liquid of the membrane. After the feed is finished, dilute the upstream liquid ...

Embodiment 2

[0090] The raw material is the adsorption resin waste water from the production process of fresh Luo Han Guo.

[0091] 1. Tertiary membrane separation refining and concentration.

[0092] (1) Pump 25,000L of adsorption resin wastewater from the production process of fresh Luo Han Guo into the ultrafiltration membrane complete system, select the ultrafiltration membrane with a molecular weight cut-off of 3KD, control the pressure at 1.5MPa, and collect the liquid downstream of the membrane. After the feed is finished, dilute the upstream liquid twice with 1000L purified water, and continue to pass through the membrane to obtain 25 500L ultrafiltration membrane refined liquid.

[0093] (2) Pump the ultrafiltration membrane refined solution into the nanofiltration membrane complete system, select the nanofiltration membrane molecular weight cut-off as 500, control the pressure at 2.5MPa, and collect the downstream liquid of the membrane. After feeding the feed, dilute the upstre...

Embodiment 3

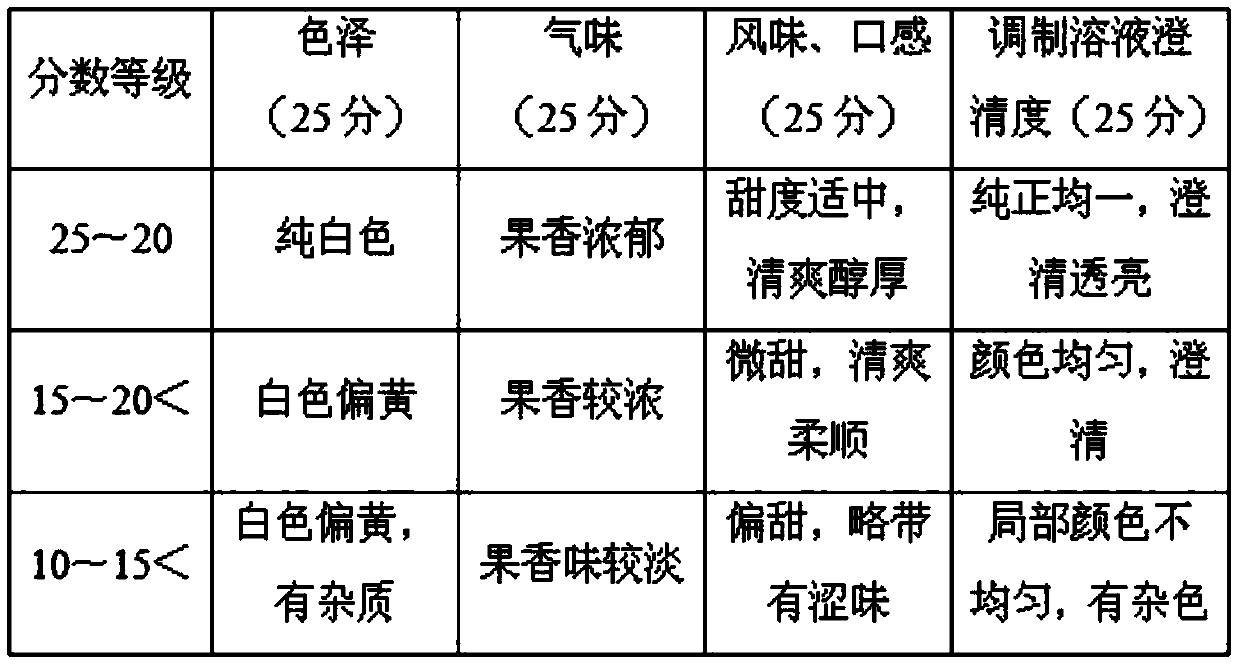

[0107] Other conditions are the same as in Example 1, except that the difference in step 1 is that the nanofiltration membrane controls the pressure at 3.5MPa, glucose 19.6%, fructose 24.4%, sucrose 8.2%, mannitol 3.4%, impurities 1.2%, and the rest for water. The amount of the final obtained natural Luo Han Guo syrup is 230L, the product purity has a certain decline, slightly yellow, the absorbance of the diluted aqueous solution (solid content 1% w / v) at 420nm is 0.07, and the mouthfeel is slightly poor. According to the standard in Table 1, the average score of 10 people is 89.4 points.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Absorbance | aaaaa | aaaaa |

| Brix | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com