Process for increasing nickel yield in ferronickel production

A yield and process technology, applied in the technical field of nickel yield, can solve the problems of rising stainless steel smelting costs, pushing up the production cost of electrolytic nickel, increasing mining difficulty, etc. The effect of unit cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

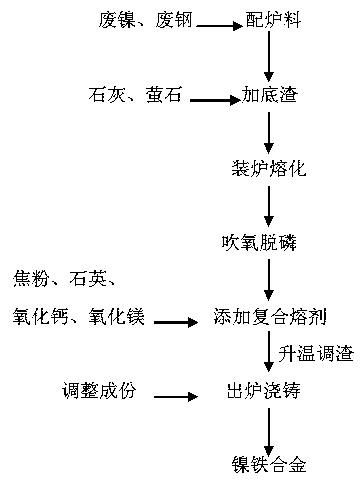

Method used

Image

Examples

Embodiment 1

[0028] Put the waste nickel and steel scrap prepared in proportion into the alkaline crucible of the intermediate frequency induction furnace, and spread the bottom slag accounting for 2.1% of the furnace charge on the bottom of the crucible. The bottom slag is composed of: lime 72% and fluorite 28%; When the temperature is 1575°C, the charge forms a molten pool in the crucible, and the bottom slag is melted and covered on the alloy liquid; insert the muzzle of the oxygen blowing device 22cm below the liquid level of the alloy liquid, and the oxygen blowing device is under a pressure of 0.15Mpa Blow oxygen into the alloy liquid for 16 minutes for dephosphorization, analyze phosphorus and sulfur before the sampling furnace, and add composite flux after passing the test; the components of the composite flux are composed as follows by weight percentage: 38% coke powder, 25% quartz, 31% oxidized Calcium, 6% magnesium oxide, wherein the particle size of coke powder is 100-150 mesh, ...

Embodiment 2

[0030] Put the waste nickel and steel scrap prepared in proportion into the alkaline crucible of the intermediate frequency induction furnace, and spread the bottom slag accounting for 2.3% of the furnace charge on the bottom of the crucible. The bottom slag is composed of: 75% lime and 25% fluorite; When the temperature is 1595°C, the charge forms a molten pool in the crucible, and the bottom slag is melted and covered on the alloy liquid; insert the muzzle of the oxygen blowing device 30cm below the liquid level of the alloy liquid, and the oxygen blowing device is under a pressure of 0.2Mpa Blow oxygen into the alloy liquid for 20 minutes for dephosphorization, analyze phosphorus and sulfur before the sampling furnace, and add composite flux after passing the test; the components of the composite flux are composed as follows by weight percentage: 35% coke powder, 25% quartz, 35% oxidized Calcium, 5% magnesium oxide, wherein the particle size of coke powder is 100-150 mesh, the...

Embodiment 3

[0032] Put the waste nickel and steel scrap prepared in proportion into the alkaline crucible of the intermediate frequency induction furnace, and spread the bottom slag accounting for 2.5% of the furnace charge on the bottom of the crucible. The bottom slag is composed of: 70% lime and 30% fluorite; When the temperature is 1600°C, the charge forms a molten pool in the crucible, and the bottom slag is melted and covered on the alloy liquid; insert the muzzle of the oxygen blowing device 35cm below the liquid level of the alloy liquid, and the oxygen blowing device is under a pressure of 0.2Mpa Blow oxygen into the alloy liquid for 20 minutes for dephosphorization, analyze phosphorus and sulfur before the sampling furnace, and add composite flux after passing the test; the components of the composite flux are composed as follows by weight percentage: 35% coke powder, 20% quartz, 35% oxidized Calcium, 10% magnesium oxide, wherein the particle size of coke powder is 100-150 mesh, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com