Elastomer, method for preparation thereof, and use thereof

An elastomer and thermoplastic elastomer technology, applied in the field of polyurethane, its preparation, can solve the problems of delaying the commercialization of materials, and achieve the effects of low instrument cost, less by-products, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

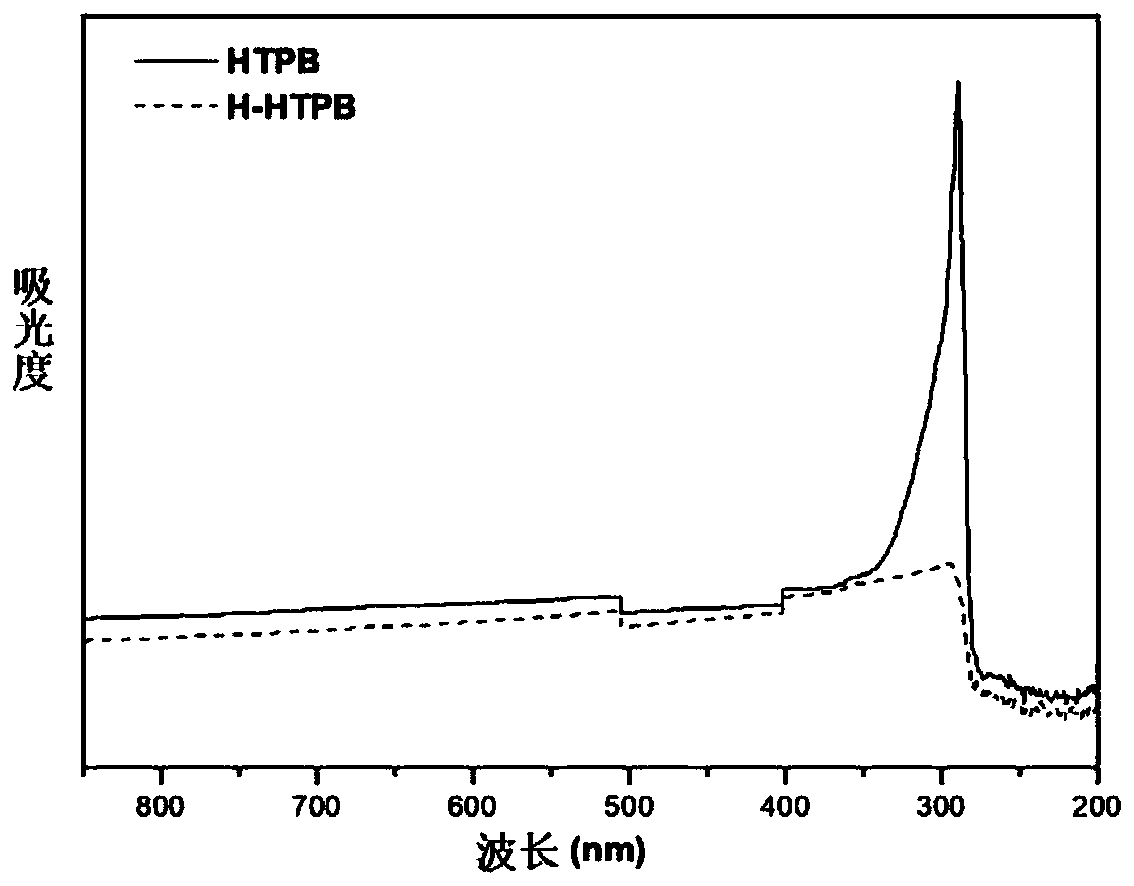

[0082] Embodiment 1: Preparation of hydrogenated diols

[0083] Add 50g polybutadiene diol and 600mL THF to the hydrogenation kettle; after the polybutadiene diol is dissolved, add 12g of Pt hydrogenation catalyst and hydrogen to the hydrogenation kettle; control the temperature at 60°C and control the pressure At 2 MPa, the reaction was continued for 20 hours until the reaction was complete; the hydrogenated diol obtained was isolated, purified and dried.

Embodiment 2

[0085] process:

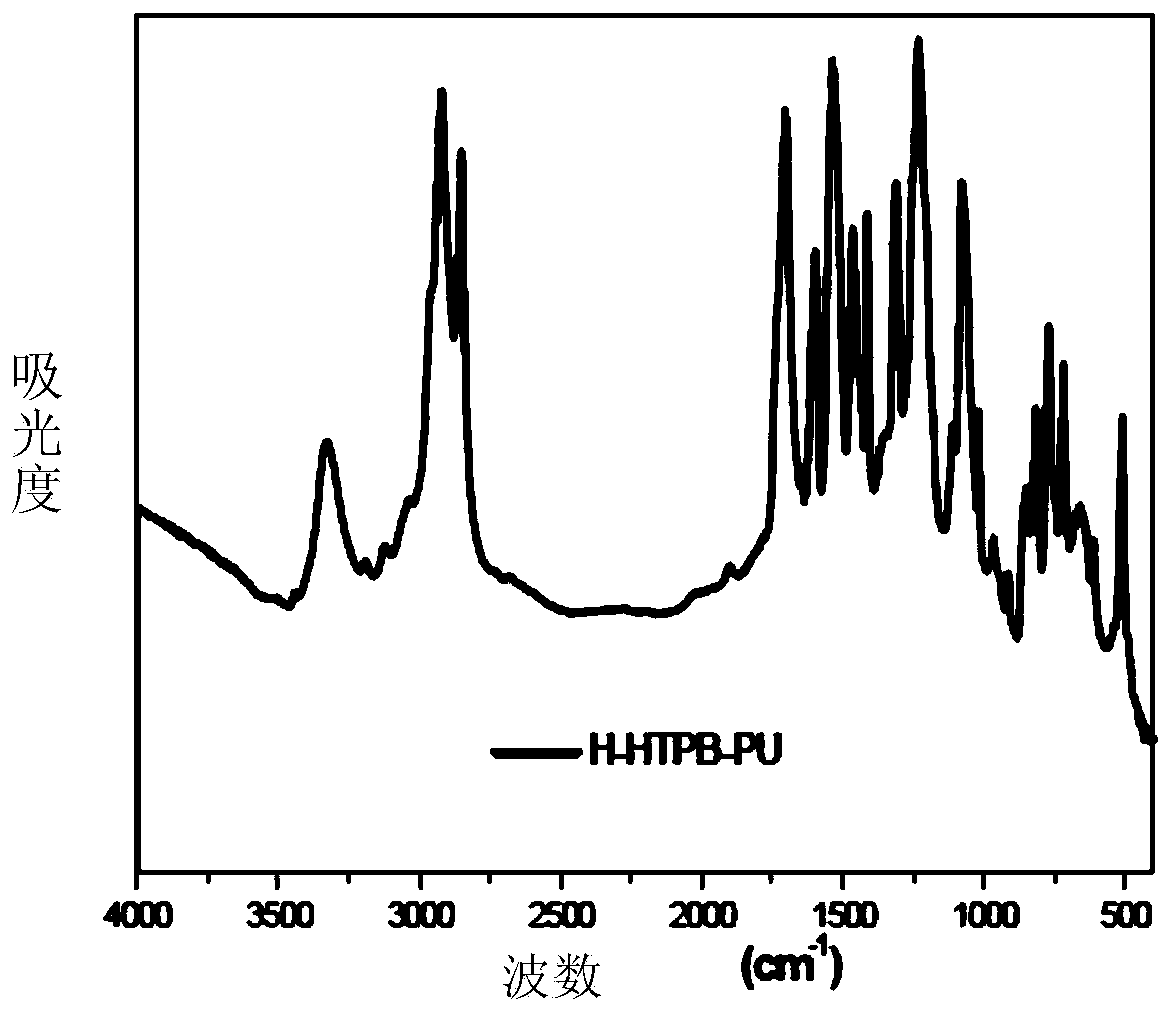

[0086] Into a 100 mL glass reactor was added 30 mL of toluene and 3.7 g of hydrogenated polybutadiene diol (H-HTPB). The mixture was stirred until H-HTPB was dissolved in toluene. Then 1.5 g of 4,4'-diphenylmethane diisocyanate was added, followed by 40 μL of dibutyltin dilaurate catalyst. The reaction mixture was then heated using microwave irradiation (400W) to maintain its temperature at 65°C while stirring. After 2 hours of reaction, 0.36 g of chain extender BDO (calculated based on the amount of titrated isocyanate so that the total moles of OH is the same as that of isocyanate); then the temperature was raised to 80°C by increasing the microwave power to 500W . The reaction was allowed to continue for another 2 hours. Based on FI-IR testing, the reaction was terminated when the isocyanate was completely reacted. The reaction solution was poured into methanol to precipitate a polymer product. Place the mixture in the refrigerator for 24 hours. A s...

Embodiment 3

[0092] process:

[0093] Add 30 mL of toluene to a 100 mL glass reactor and heat to 65 °C. 3.7 g of hydrogenated polybutadiene diol (H-HTPB) was added to the reactor. The mixture was stirred until H-HTPB was dissolved in toluene. Then 1.5 g of 4,4'-diphenylmethane diisocyanate was added, followed by 40 μL of dibutyltin dilaurate catalyst. The reaction mixture was heated with a conventional heater to maintain its temperature at 65°C while stirring. After 5 hours of reaction, 0.36 g of chain extender BDO (calculated based on the amount of isocyanate titrated so that the total moles of OH is the same as that of isocyanate); then the temperature was raised to 80° C. by increasing the heating power. The reaction was allowed to continue for another 5 hours. Based on FI-IR testing, the reaction was terminated when the isocyanate was completely reacted. The reaction solution was poured into methanol to precipitate a polymer product. Place the mixture in the refrigerator for 24 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tensile modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com