Nanometer composite material FAPbBr3/SiO2, preparation method and applications thereof

A nanocomposite material, fapbbr3 technology, applied in the field of lasers, can solve problems such as difficult control of shell thickness, instability of FAPbX3 quantum dots hindering the development of optoelectronic devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

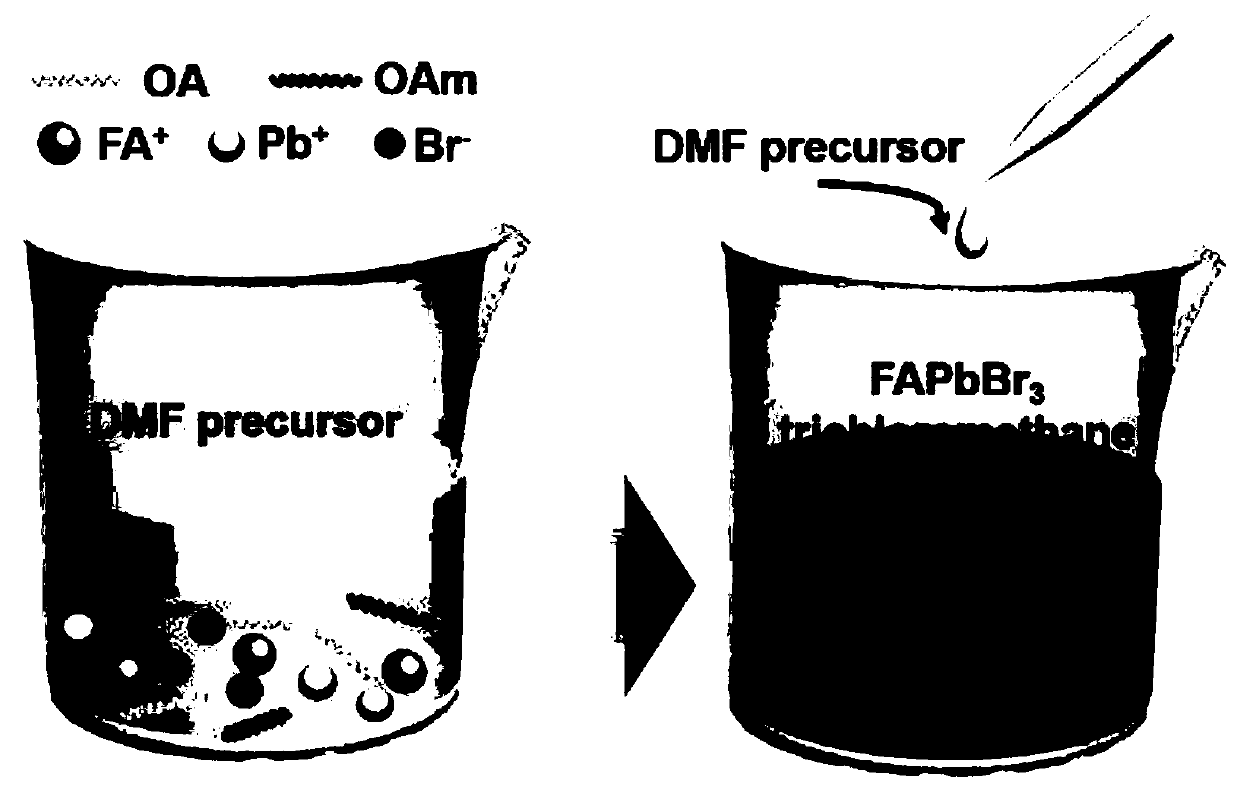

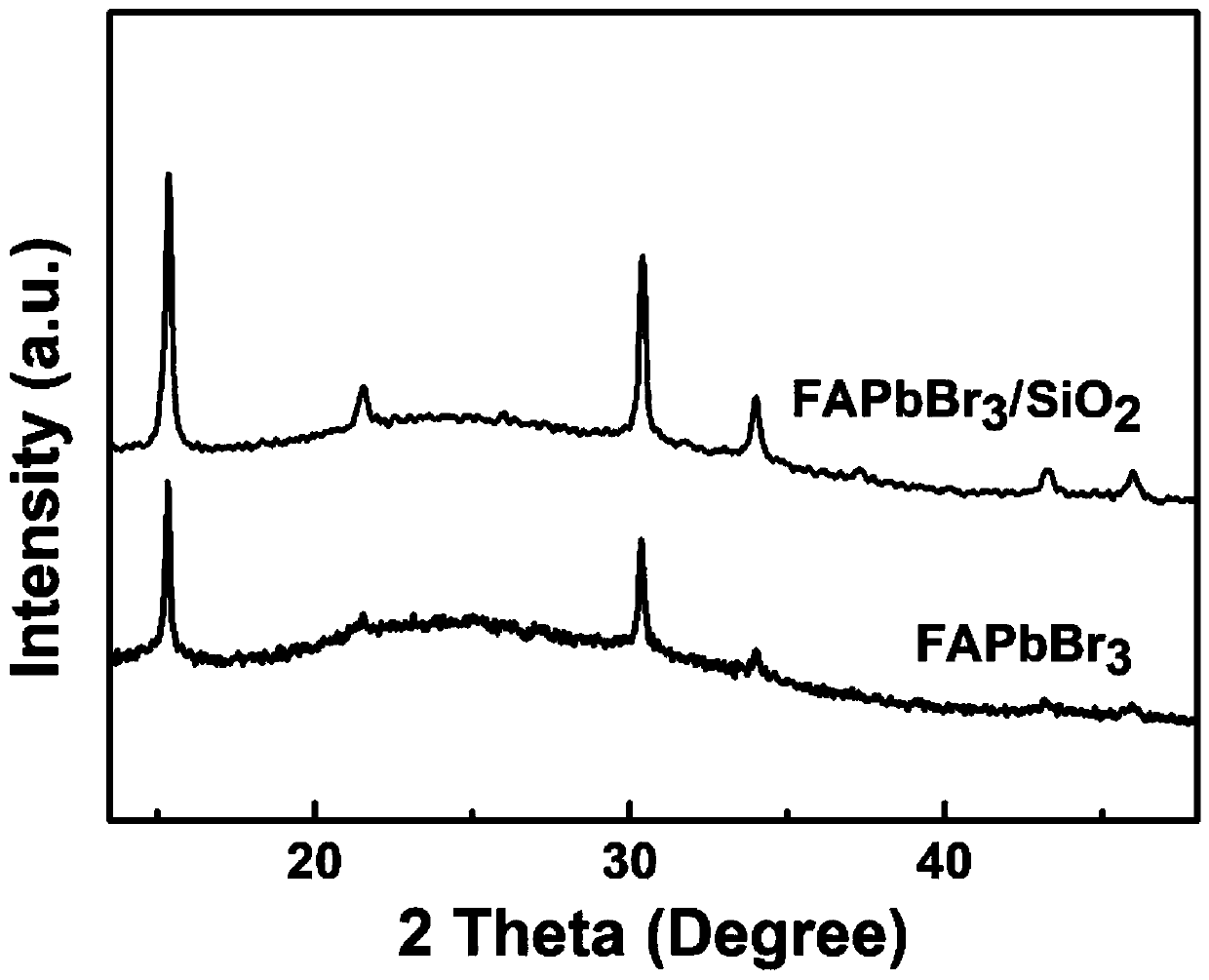

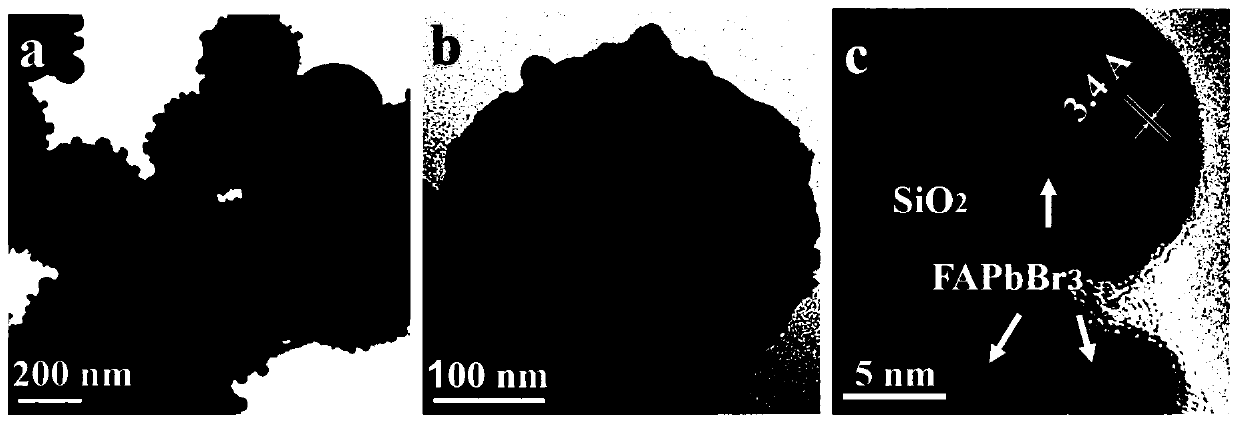

[0056] 1. Preparation and amination of silicon spheres: take 20 ml of absolute ethanol, 2 ml of deionized water, 0.4 ml of ammonia water, and 0.4 ml of tetraethyl orthosilicate (TEOS). After stirring for 1 hour, the purification operation was carried out at 2000 r / s for 2 minutes, followed by three times of purification and centrifugation with ethanol at the same rotation speed and duration and drying. Take 0.5 g of nanospheres, inject 10 ml of absolute ethanol, 0.6 ml of 3-aminopropyltriethoxysilane (APTES), stir continuously for 1 hour, and purify and dry in the same way to obtain aminated SiO 2 Nanospheres.

[0057] 2. Take 10mg of FABr and 30mg of PbBr 2 Dissolve in 1 ml of DMF and stir well. Pour 45 mg of aminated SiO into the solution 2 Silicon balls, stir well.

[0058] 3. Take 1ml of precursor solution, add 100ml of oleic acid and 30ml of oleylamine, and stir for 5 minutes. Take 100 µl of FAPbBr 3 / SiO 2 The nucleation solution was added dropwise to a stirred so...

Embodiment 2

[0060] 1. Preparation and amination of silicon spheres:

[0061] Take 20 ml of absolute ethanol, 10 ml of deionized water, 1.2 ml of ammonia water, and 1.2 ml of tetraethyl orthosilicate (TEOS). After stirring for 8 hours, the purification operation was carried out at a rotation speed of 8000 r / s for 5 minutes, followed by three times of purification and centrifugation operations with ethanol at the same rotation speed and duration and drying. Take 2 grams of nanospheres, inject 20ml of absolute ethanol, 4ml of 3-aminopropyltriethoxysilane (APTES), stir continuously for 8 hours, purify and dry in the same way to obtain aminated SiO 2 Nanospheres.

[0062] 2. Take 60mg of FABr and 180mg of PbBr 2 Dissolve in 4 ml of DMF and stir well. Pour 220 mg of aminated SiO into the solution 2 Silicon balls, stir well.

[0063] 3. Take 1ml of precursor solution, add 300ml of oleic acid and 50ml of oleylamine, and stir for 5 minutes. Take 100 µl of FAPbBr 3 / SiO 2 The nucleation sol...

Embodiment 3

[0065] 1. Preparation and amination of silicon spheres:

[0066] Take 14.8 ml of absolute ethanol, 2 ml of deionized water, 0.63 ml of ammonia water, and 1.2 ml of tetraethyl orthosilicate (TEOS). After stirring for 8 hours, the purification operation was carried out at a rotation speed of 8000 r / s for 2 minutes, followed by three times of purification and centrifugation operations with ethanol at the same rotation speed and duration and drying. Take 0.6 g of nanospheres, inject 10 ml of absolute ethanol, 1 ml of 3-aminopropyltriethoxysilane (APTES), stir continuously for 8 hours, and purify and dry in the same way to obtain aminated SiO 2 Nanospheres.

[0067] 2. Take 22.4mg of FABr and 73.4mg of PbBr 2 Dissolve in 2 ml of DMF and stir well. Pour 100 mg of aminated SiO into the solution 2 Silicon balls, stir well.

[0068] 3. Take 2ml of precursor solution, add 400ml of oleic acid and 80ml of oleylamine, and stir for 5 minutes. Take 100 µl of FAPbBr 3 / SiO 2 The nucle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com