Spraying material for coal mine underground roadway and preparation method of spraying material

A technology for spraying materials and underground tunnels, which is applied in the field of spraying materials for construction of underground tunnels in coal mines and the field of preparation of the materials, can solve the problems of restricting the driving speed, many potential safety hazards, and large dust pollution, and achieves low labor intensity for workers and material saving. The effect of dosage and saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

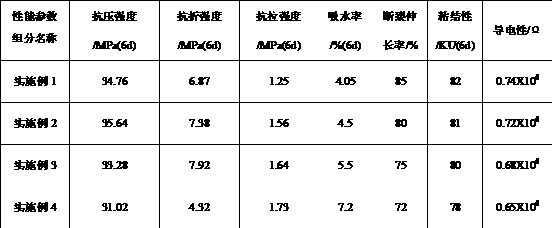

Embodiment 1

[0057] 25 parts of polymer emulsion, 0.12 parts of polypropylene fiber, 100 parts of inorganic bonding material, 150 parts of coal ash powder, 1 part of heavy calcium carbonate, 0.2 part of hydroxypropyl methylcellulose ether, 0.5 part of water reducing agent, 0.2 parts of strong agent, 45 parts of flame retardant, 15 parts of graphite powder, 5 parts of inorganic filler. Fully stir the composition of the above materials in a twin-screw high-efficiency mixer for 20 minutes, mix and stir evenly, then add an appropriate amount of water, and mix evenly.

Embodiment 2

[0059] 27 parts of polymer emulsion, 0.15 parts of polypropylene fiber, 100 parts of inorganic bonding material, 200 parts of coal ash powder, 25 parts of heavy calcium carbonate, 0.25 parts of hydroxypropyl methylcellulose ether, 0.55 parts of water reducing agent, early 0.22 parts of strong agent, 48 parts of flame retardant, 18 parts of graphite powder, 6 parts of inorganic filler. Fully stir the composition of the above materials in a twin-screw high-efficiency mixer for 20 minutes, mix and stir evenly, then add an appropriate amount of water, and mix evenly.

Embodiment 3

[0061] 30 parts of polymer emulsion, 0.17 parts of polypropylene fiber, 100 parts of inorganic bonding material, 250 parts of coal ash powder, 40 parts of heavy calcium carbonate, 0.26 parts of hydroxypropyl methylcellulose ether, 0.6 parts of water reducing agent, 0.25 parts of strong agent, 55 parts of flame retardant, 20 parts of graphite powder, 8 parts of inorganic filler. Fully stir the composition of the above materials in a twin-screw high-efficiency mixer for 20 minutes, mix and stir evenly, then add an appropriate amount of water, and mix evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com