Foliar fertilizer for Camellia oleifera

A technology of foliage fertilizer and camellia oleifera, which is applied in the direction of application, potash fertilizer, organic fertilizer, etc., can solve the problems of lack of growth and firmness of camellia oleifera, the wax on the surface of camellia oleifera and the absorption rate of cuticle, etc., so as to improve disease resistance and improve Drought resistance and high nutrient absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A foliage fertilizer for camellia oleifera, comprising the following raw materials in parts by weight: 40 parts of quinoa liquid, 15 parts of plant ash, 0.12 part of shallot powder, 0.8 part of neem bark powder, 0.9 part of betel nut powder, 6 parts of chicken manure liquid, wormwood 50 parts of liquid;

[0029] The quinoa liquid is made by drying quinoa with hot air for 16 minutes under the environment of 58° C., and then performing intermittent microwave treatment on the quinoa bran. 15s, the microwave treatment temperature does not exceed 100°C, crush the quinoa bran through an 80-mesh sieve, wrap the powder with filter paper, alkalize it in ammonia water, transfer it to a Soxhlet extractor, and extract it with absolute ethanol Quinoa liquid was extracted at a constant temperature of 78°C for 1.7 hours; the concentration of the ammonia water was 40%; the solid-liquid ratio of the powder to absolute ethanol was 1:10;

[0030] The wormwood liquid is prepared by placin...

Embodiment 2

[0038] A foliage fertilizer for camellia oleifera, comprising the following raw materials in parts by weight: 40 parts of quinoa liquid, 15 parts of plant ash, 0.12 part of shallot powder, 0.8 part of neem bark powder, 0.9 part of betel nut powder, 6 parts of chicken manure liquid, wormwood 50 parts of liquid;

[0039] The quinoa liquid is made by drying quinoa with hot air for 10 minutes at 55° C., and then intermittently microwave-treating the quinoa bran. 15s, the microwave treatment temperature does not exceed 100°C, crush the quinoa bran through an 80-mesh sieve, wrap the powder with filter paper, alkalize it in ammonia water, transfer it to a Soxhlet extractor, and extract it with absolute ethanol Quinoa liquid was extracted at a constant temperature of 58°C for 0.7h; the concentration of the ammonia water was 30%; the solid-liquid ratio of the powder to absolute ethanol was 1:5;

[0040] The wormwood liquid is prepared by placing the wormwood in an ethanol solution wit...

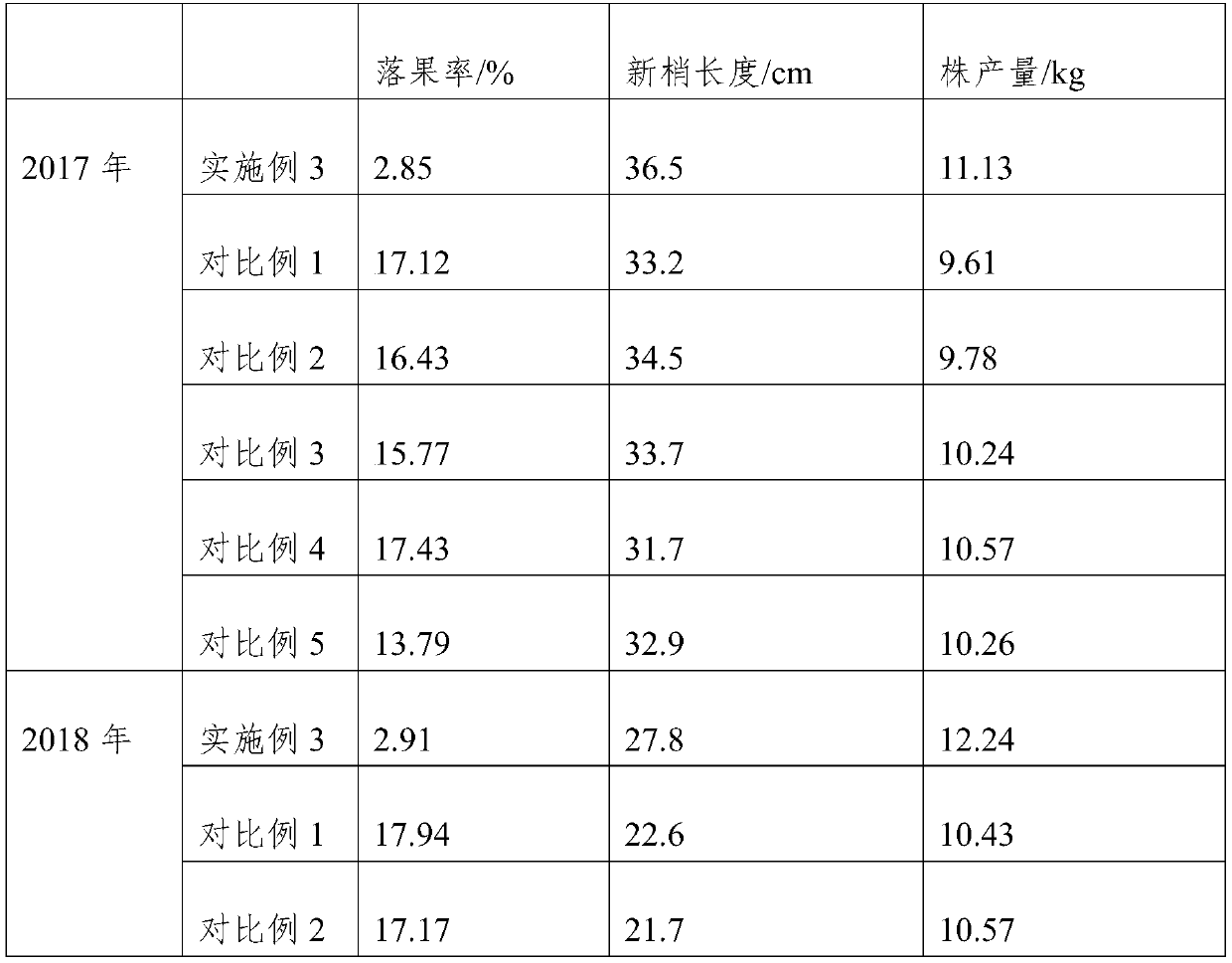

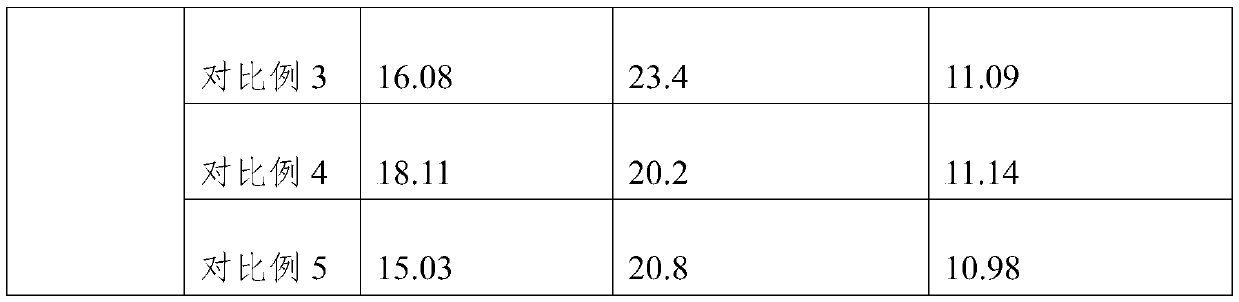

Embodiment 3

[0048] A foliage fertilizer for camellia oleifera, comprising the following raw materials in parts by weight: 35 parts of quinoa liquid, 13 parts of plant ash, 0.08 part of onion silk powder, 0.5 part of neem bark powder, 0.6 part of betel nut powder, 4 parts of chicken manure liquid, wormwood 45 parts of liquid;

[0049] The quinoa liquid is made by drying quinoa with hot air for 13 minutes at 56° C., and then intermittently microwave-treating the quinoa bran. 15s, the microwave treatment temperature does not exceed 100°C, crush the quinoa bran through an 80-mesh sieve, wrap the powder with filter paper, alkalize it in ammonia water, transfer it to a Soxhlet extractor, and extract it with absolute ethanol Quinoa liquid was extracted at a constant temperature of 68°C for 1.2 hours; the concentration of the ammonia water was 35%; the solid-liquid ratio of the powder to absolute ethanol was 1:7;

[0050] The wormwood liquid is prepared by placing the wormwood in an ethanol solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com