Perovskite single crystal with light trapping structure and preparation method of perovskite single crystal

A light-trapping structure and perovskite technology, which is applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of unpublished preparation of perovskite single crystals and the inability to form them at one time, and meet the equipment requirements Low, mild growth conditions, simple method and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

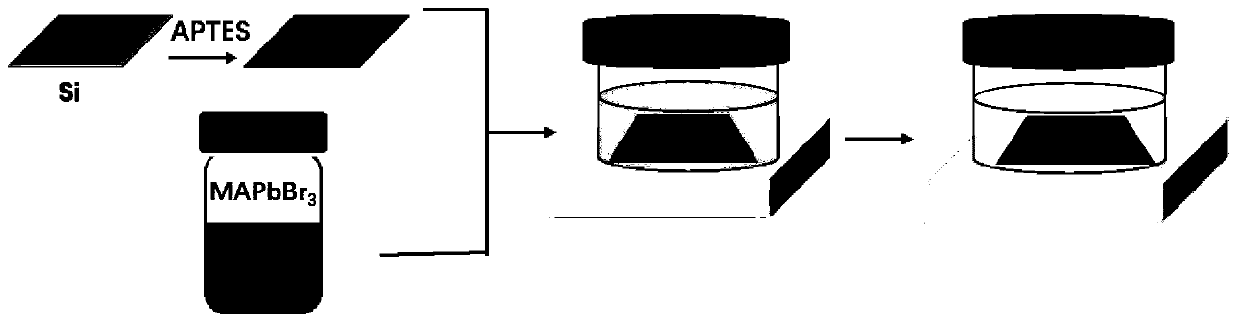

[0040] Step 1, cleaning the single crystal silicon with a pyramid structure with an average surface diameter of 1 μm: ultrasonic cleaning with acetone, isopropanol and ultrapure water for 15 minutes respectively.

[0041] Step 2, perform surface modification treatment on the template: place the single crystal silicon wafer in 3-aminopropyltrimethoxysilane diluted 10:1 with chlorobenzene, and activate treatment at 60° C. for 20 minutes.

[0042] Step 3, configure the precursor single crystal growth solution: weigh CH with a stoichiometric ratio of 1:1 3 NH 3 I and PbI 2 , dissolved in 20mL γ-butyrolactone to obtain 1.23mol / L clear and transparent CH 3 NH 3 PB 3 Precursor Growth Solution.

[0043] Step 4, growing a perovskite single crystal with a surface light-trapping structure: transfer the template and the configured precursor liquid to a closed container. The reaction container system is placed in a heated blast drying oven and the temperature is raised to 95°C. After...

Embodiment 2

[0046] Step 1, cleaning the single crystal silicon with a pyramid structure with an average surface diameter of 10 μm: ultrasonic cleaning with acetone, isopropanol and ultrapure water for 15 minutes respectively.

[0047] Step 2, perform surface modification treatment on the template: place the single crystal silicon wafer in 3-aminopropyltriethoxysilane diluted 10:1 with chlorobenzene, and activate treatment at 50° C. for 40 minutes.

[0048] Step 3, configure the precursor single crystal growth solution: weigh CH with a stoichiometric ratio of 1:1 3 NH 3 Br and PbBr 2 , dissolved in 20mL N,N dimethylformamide to obtain 1.5mol / L clear and transparent CH 3 NH 3 PbBr 3 Precursor Growth Solution.

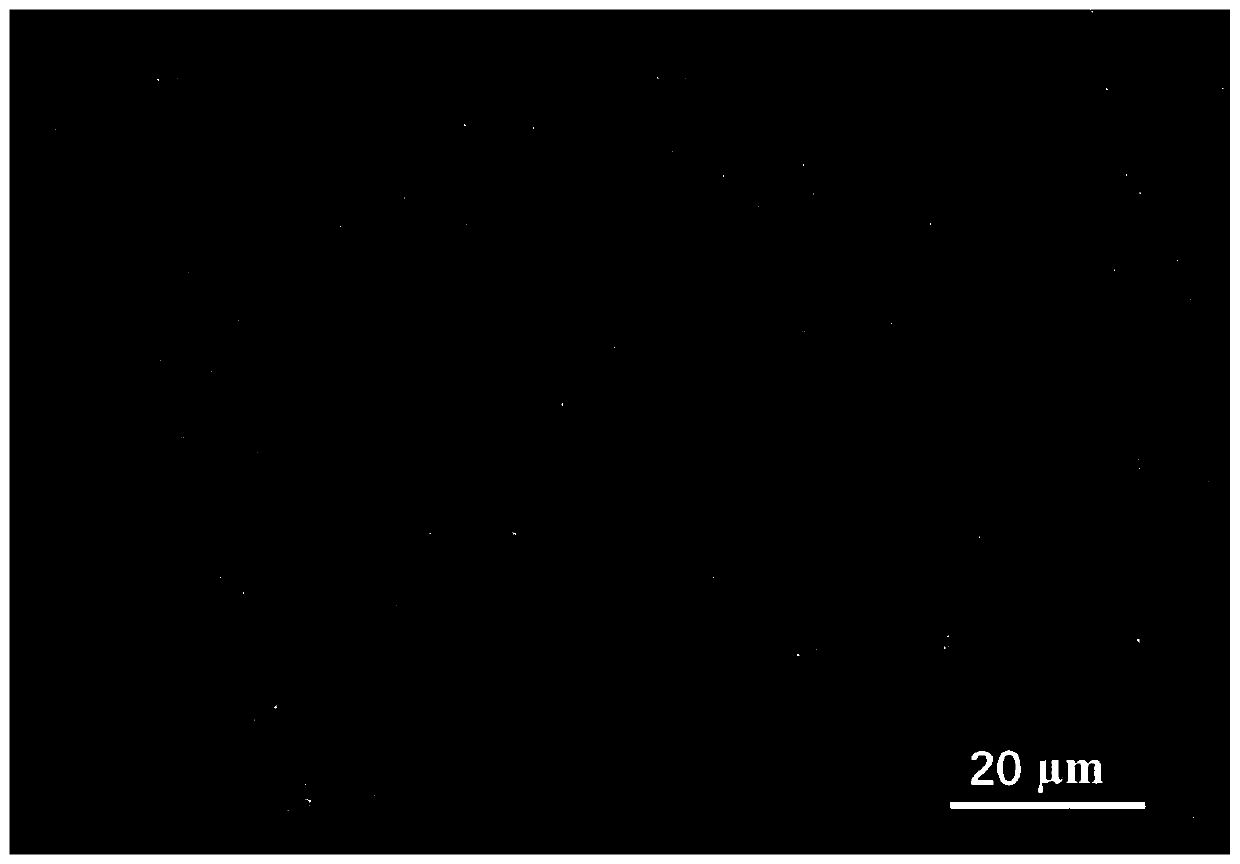

[0049] Step 4, growing a perovskite single crystal with a surface light-trapping structure: transfer the template and the configured precursor liquid to a closed container. The reaction container system is placed in a heated blast drying oven and the temperature is raised to 50...

Embodiment 3

[0052] Step 1, cleaning the single crystal silicon with a pyramid structure with an average surface diameter of 5 μm: ultrasonic cleaning with acetone, isopropanol and ultrapure water for 15 minutes respectively.

[0053] Step 2, perform surface modification treatment on the template: place the monocrystalline silicon wafer in mercaptopropyltrimethoxysilane diluted 10:1 with chlorobenzene, and perform activation treatment at 70° C. for 40 minutes.

[0054] Step 3, configure the precursor single crystal growth solution: weigh CH with a stoichiometric ratio of 1:1 3 NH 3 Cl and PbCl 2 , dissolved in 20mL dimethyl sulfoxide to obtain 2.5mol / L clear and transparent CH 3 NH 3 PbCl 3 Precursor Growth Solution.

[0055] Step 4, growing a perovskite single crystal with a surface light-trapping structure: transfer the template and the configured precursor liquid to a closed container. The reaction container system is placed in a heated blast drying oven and the temperature is rai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com