Preparation method for tungsten disulfide/MXene composite material

A composite material, tungsten disulfide technology, applied in chemical instruments and methods, tungsten compounds, carbides, etc., can solve the problems of low electrical conductivity and limited rate performance, and achieve good dispersion, uniform morphology and product output. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

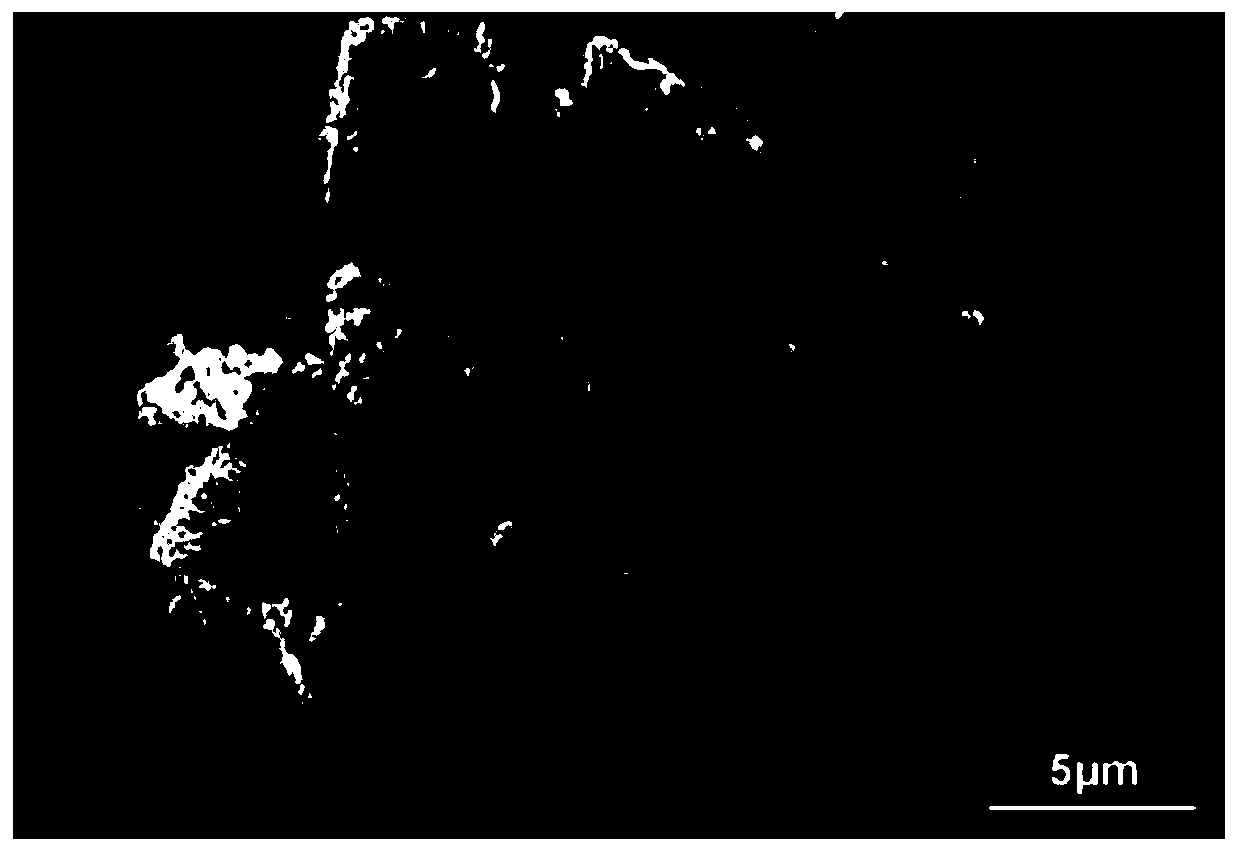

[0028] Add 10mL of concentrated hydrochloric acid to 14mL of deionized water to make a 5mol / L hydrochloric acid solution, slowly pour 1.5g of lithium fluoride into the prepared hydrochloric acid solution, stir and react for 5min, then slowly add 0.96g of Ti 3 AlC 2 powder, stirred at 40°C for 24h with a magnetic stirrer, washed with water, centrifuged, and dried at 60°C for 12h to obtain the MXene material Ti 3 C 2 powder, the resulting MXene material Ti 3 C 2 The SEM photograph of the powder is as figure 1 As shown, it can be seen that the MXene material Ti after etching 3 C 2 It shows an obvious organ-like multi-layer structure.

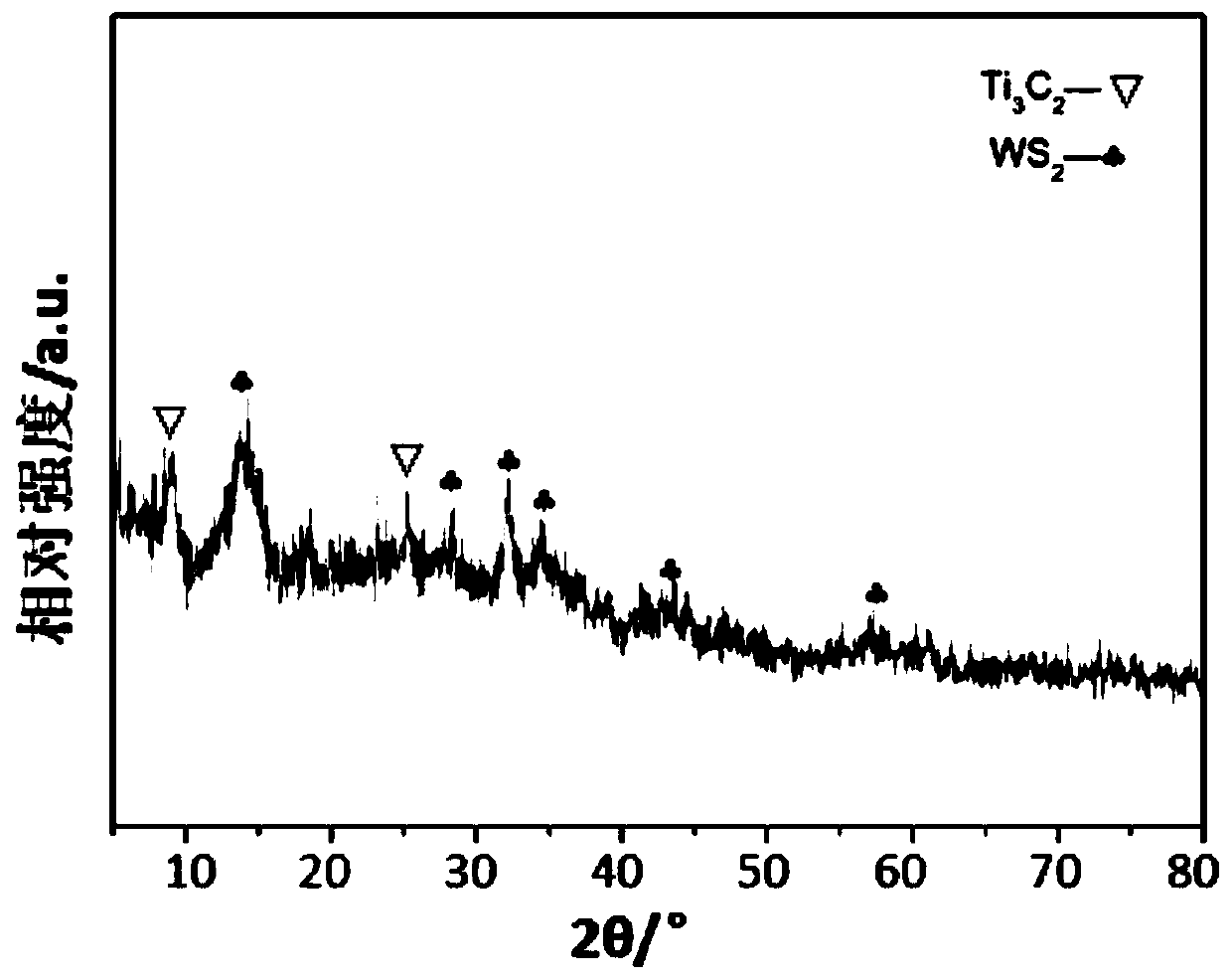

[0029] Weigh the prepared MXene material Ti 3 C 2 Pour 90 mg of the powder into 30 mL of deionized water, ultrasonically disperse for 30 min, then add 0.66 g of sodium tungstate dihydrate, 0.78 g of thiourea, and 0.5 g of oxalic acid to the MXene solution, and stir for 20 min to obtain a precursor solution. Transfer to a hydrothermal react...

Embodiment 2

[0033] Add 10mL of concentrated hydrochloric acid to 20mL of deionized water to make a 4mol / L hydrochloric acid solution, slowly pour 1.4g of lithium fluoride into the prepared hydrochloric acid solution, stir for 8min, then slowly add 1.05g of Ti 3 AlC 2 powder, stirred at 40°C for 36h with a magnetic stirrer, washed with water, centrifuged, and vacuum-dried at 60°C for 12h to obtain the MXene material Ti 3 C 2 powder.

[0034] Weigh the prepared MXene material Ti 3 C 2 Pour 150mg of powder into 30mL of deionized water, ultrasonically disperse for 30min, then add 0.99g of sodium tungstate dihydrate, 1.14g of thiourea, and 0.6g of oxalic acid to the MXene solution, and stir for 20min to obtain a precursor solution. Transfer to a hydrothermal reaction kettle with a volume of 50mL; carry out hydrothermal reaction at 260°C for 20h, then cool naturally, after centrifugation, wash with deionized water and ethanol three times, and finally put the centrifuged black sample into V...

Embodiment 3

[0037] Add 10mL of concentrated hydrochloric acid to 30mL of deionized water to make a 3mol / L hydrochloric acid solution, slowly pour 1.5g of lithium fluoride into the prepared hydrochloric acid solution, stir for 8min, then slowly add 1.4g of Ti 3 AlC 2powder, stirred at 40°C for 24 hours with a magnetic stirrer, washed with water, centrifuged, and vacuum-dried at 60°C for 12 hours to obtain the MXene material Ti 3 C 2 powder.

[0038] Weigh the prepared MXene material Ti 3 C 2 Pour 120mg of powder into 30mL of deionized water, ultrasonically disperse for 30min, then add 0.5g of sodium tungstate dihydrate, 0.58g of thiourea, and 0.45g of oxalic acid into the solution, stir for 20min to obtain a precursor solution, and finally transfer the precursor solution to Put it into a hydrothermal reaction kettle with a volume of 50mL; conduct a hydrothermal reaction at 250°C for 26 hours, then cool naturally, after centrifugation, wash with deionized water and ethanol three times e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com