Technology for treating fracturing flow-back fluid of oil and gas field through multi-metal catalytic oxidation

A fracturing flowback fluid, catalytic oxidation technology, applied in the direction of oxidized water/sewage treatment, special compound water treatment, water/sewage multi-stage treatment, etc., can solve the problems of reducing pollution, pollution, and difficult to be degraded, etc. To achieve the effect of improving biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

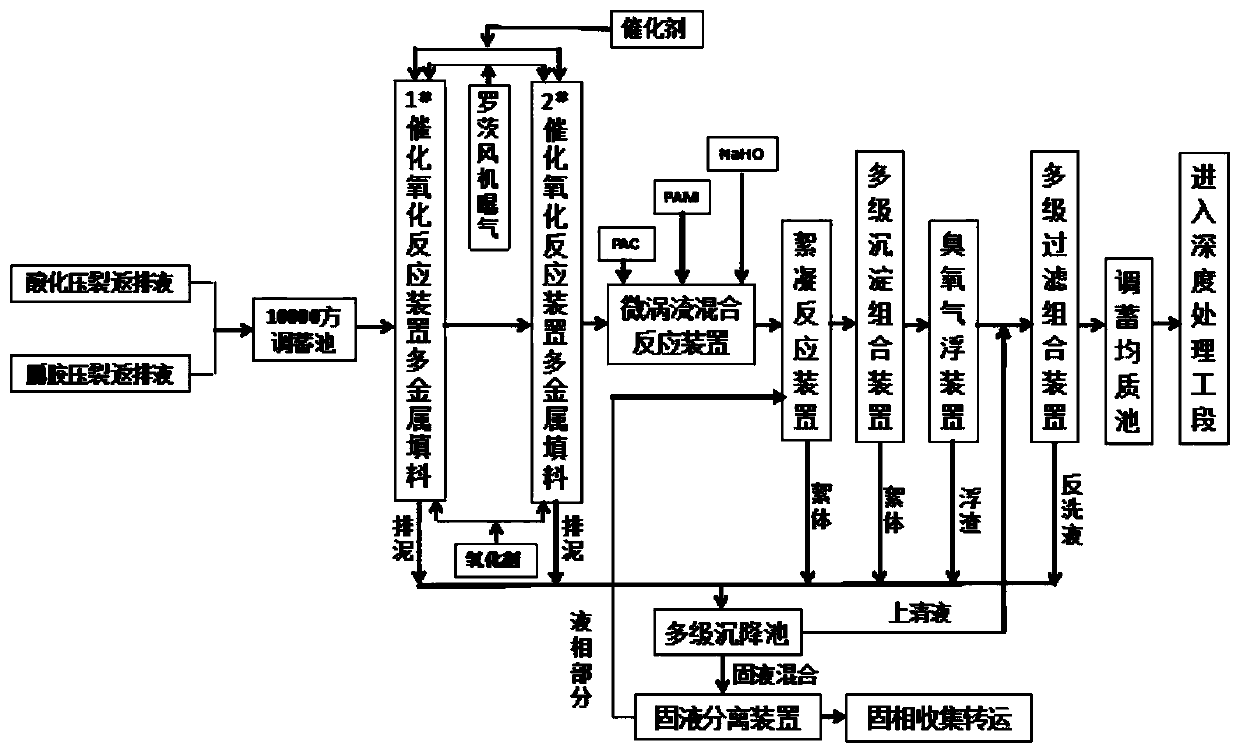

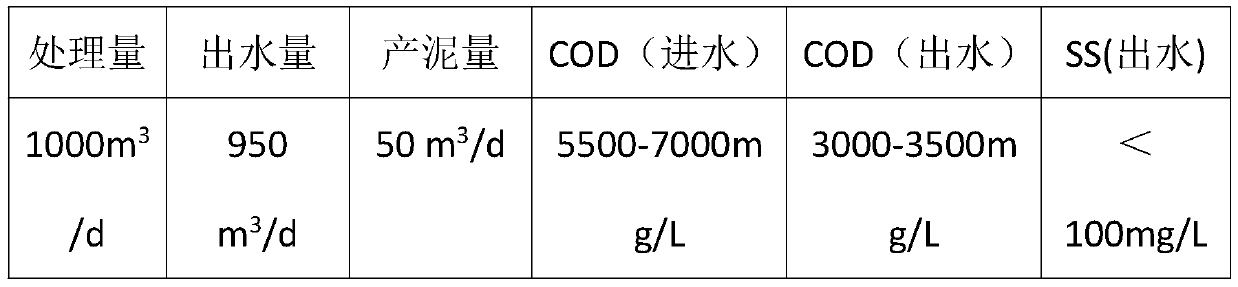

[0028] Example 1: The fracturing fluid pretreatment system mainly includes multi-metal catalytic oxidation, coagulation sedimentation, air flotation, filtration and plate and frame filter press. The influent COD of the pretreatment system is 5500-7000mg / L; the pretreatment effluent COD is 3000-3500mg / L, and the SS is less than 100mg / L.

[0029] See Table 1 for fracturing fluid pretreatment process indicators:

[0030]

[0031] Process index of fracturing fluid pretreatment section

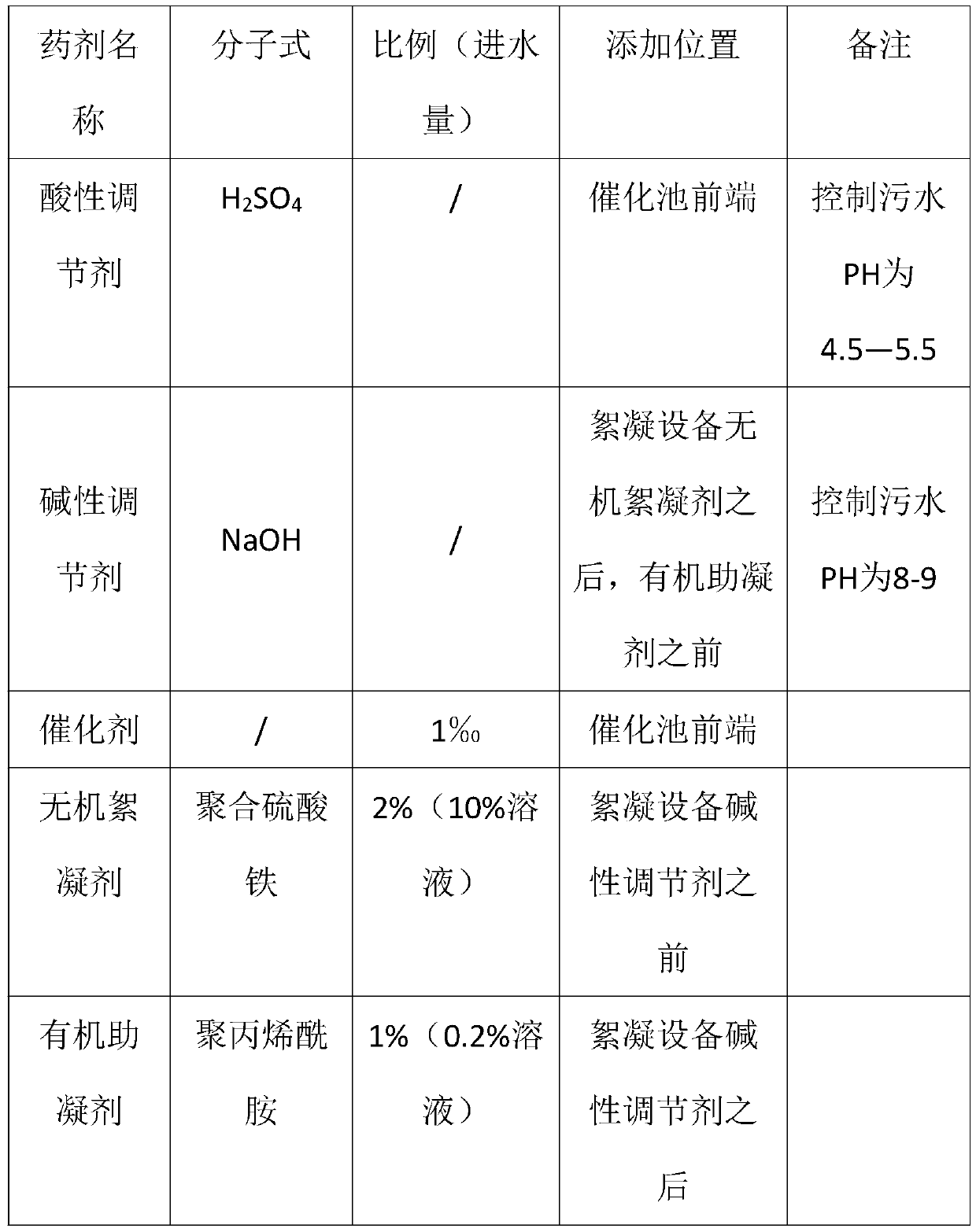

[0032] See Table 2 for details of chemicals required for the fracturing fluid pretreatment process:

[0033]

[0034] Table 2 Description of agents in the fracturing fluid pretreatment section

Embodiment 2

[0035] Example 2: Multi-metal catalytic oxidation technology is a new type of oxidation technology belonging to advanced oxidation technology. In addition to the advantages of advanced oxidation, this technology inherits the characteristics of traditional Fenton's strong oxidation ability, which is of great help to improve the biodegradability, solubility and coagulation of wastewater, and is beneficial to the subsequent treatment of wastewater. In multi-metallic fillers, doping a small amount of Fe3-xNix04, Fe3-xCox04 and Fe3-xMnx04transition metals can significantly improve the catalytic activity of the catalyst for H2O2decomposition, and Mn and Co can enhance the catalytic activity of magnetite. The iron source is stable in the internal structure of the catalyst, and can effectively generate light radicals·OH in the process of catalyzing hydrogen peroxide, the degree of restriction by the pH of the reaction will be reduced, and the reaction will not be accompanied by iron hy...

Embodiment 3

[0038] Example 3: Using a high-efficiency composite flocculant to carry out bridging flocculation on water samples after advanced oxidation and deboronation treatment, and realize the separation of oil, SS and organic pollutants in sewage in this unit. This unit integrates pH Adjustment, coagulation reaction, flocculation and precipitation separation are integrated. Under the action of coagulant and return sludge, the sewage in the flocculation reaction zone forms a high-concentration suspended sludge layer to increase the chance of particle collision and effectively absorb colloids and suspended solids. , CODcr and other pollutants, realize the coagulation, cohesion and precipitation separation of SS and fine particles in wastewater, and reduce the difficulty of treatment for subsequent filtration units. In the flocculation unit, the pipes are arranged reasonably to ensure that the effluent passes through the baffles of the flocculation tank evenly. In the baffles of the floc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com