Preparation method of mullite whisker low-temperature growth toughening type aluminum-phosphate-based high-temperature adhesive

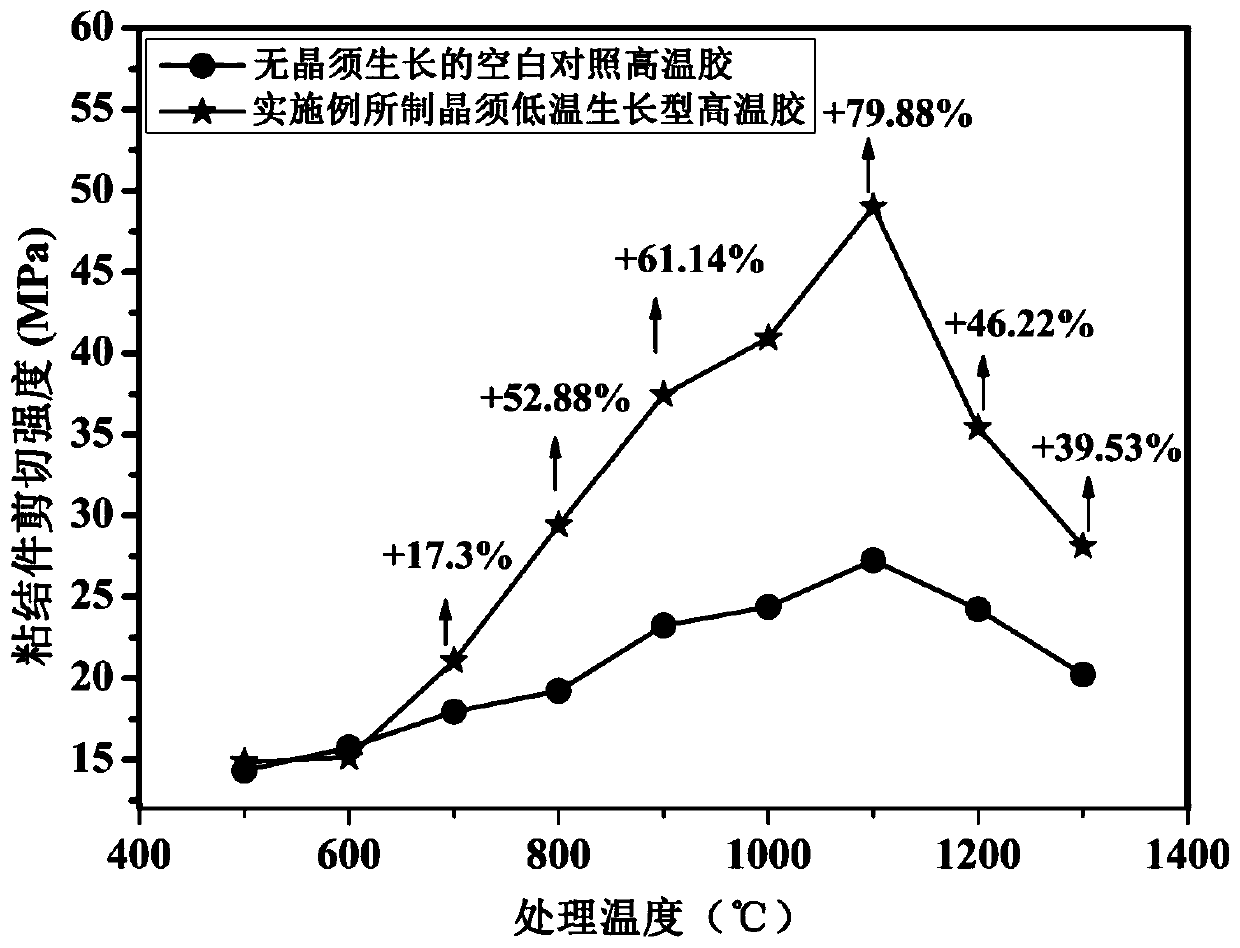

A mullite whisker and aluminum phosphate-based technology is applied in the field of preparation of mullite whisker low-temperature growth toughened aluminum phosphate-based high-temperature glue, which can solve the problem of high starting temperature and limit the growth of mullite whisker in situ. Tough technology can implement temperature range and other issues to achieve the effects of improved bonding effect, extended fracture displacement, and high damage tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

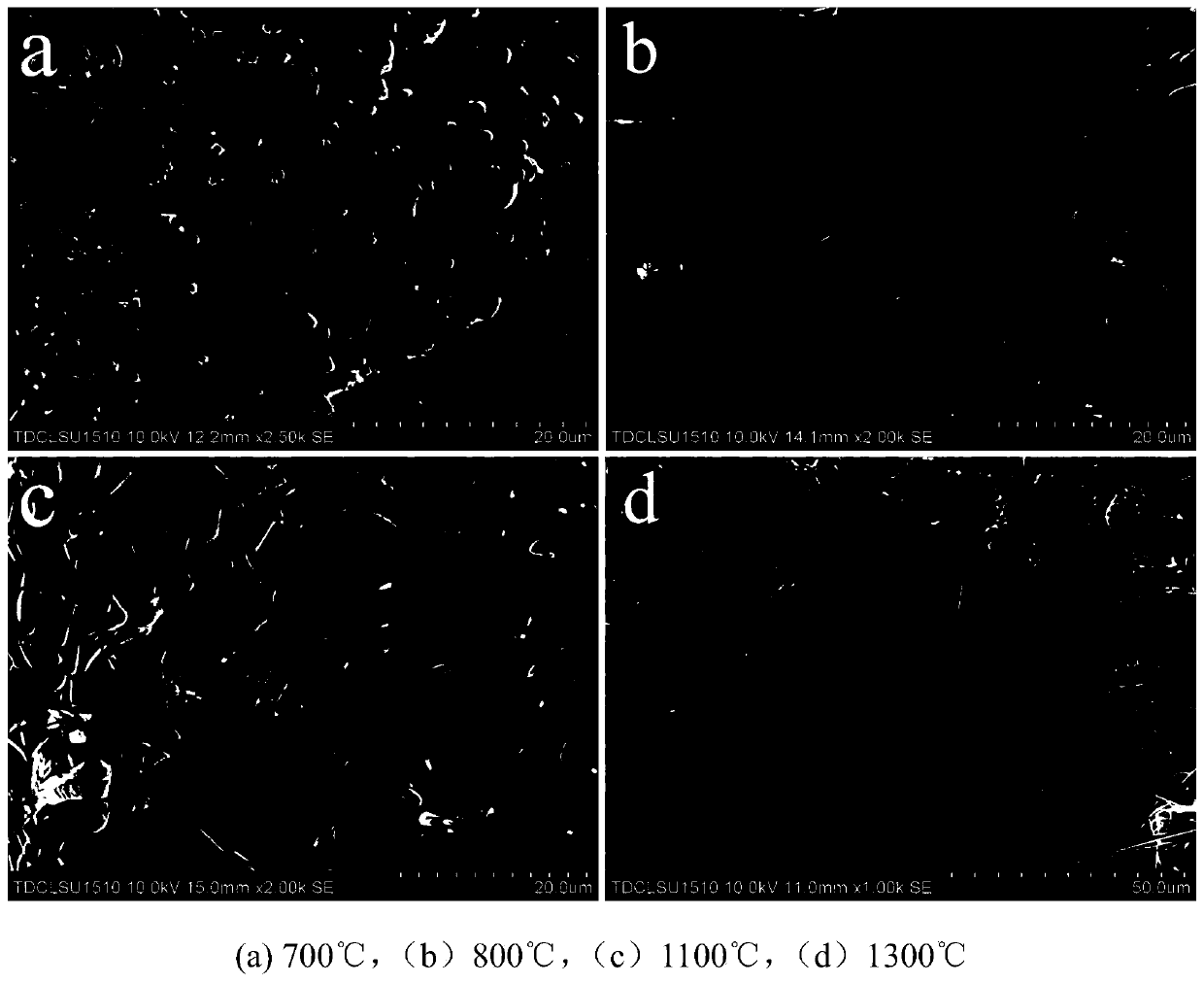

[0026] The method for preparing mullite whisker low-temperature growth toughened aluminum phosphate-based high-temperature glue provided in this example includes the following steps in order:

[0027] (1) Aluminum hydroxide powder, kaolin powder and ammonium molybdate tetrahydrate powder are mixed in a weight ratio of 1.21:1:0.293, then placed in a high-energy ball mill, and ball milled for 3 hours at a speed of 600r / min to obtain whiskers growth precursors;

[0028] (2) Alumina powder, silicon powder, boron carbide powder and BYBSO 2 The low-temperature molten glass powder is fully mixed with a weight ratio of 1.75:2.5:1.5:1.5 to make a raw material mixture;

[0029] (3) Dilute concentrated phosphoric acid with a concentration of 85% to 60% with water, and place it in a water bath at 85°C, then mix aluminum hydroxide powder into dilute phosphoric acid, wherein the molar ratio of Al:P is 1: 1. Continue mechanical stirring until it becomes a milky white glue solution with a v...

Embodiment 2

[0032] (1) Aluminum hydroxide powder, kaolin powder and ammonium molybdate tetrahydrate powder are mixed in a weight ratio of 1.21:1:0.232, then placed in a high-energy ball mill, and ball milled at a speed of 600r / min for 2.5h to obtain a crystal whisker growth precursors;

[0033] (2) Alumina powder, silicon powder, boron carbide powder and BYBSO 2 The low-temperature molten glass powder is fully mixed with a weight ratio of 1.5:1.5:1.25:1.75 to make a raw material mixture;

[0034] (3) Dilute concentrated phosphoric acid with a concentration of 85% to 60% with water, and place it in a water bath at 85°C, then mix aluminum hydroxide powder into dilute phosphoric acid, wherein the molar ratio of Al:P is 2: 3. Continue mechanical stirring until it becomes a milky white glue solution with a viscosity of 1500mPa·s;

[0035] (4) the whisker growth precursor prepared in step (1), the raw material mixture prepared in step (2) and the glue solution prepared in step (3) are placed ...

Embodiment 3

[0037] (1) Aluminum hydroxide powder, kaolin powder and ammonium molybdate tetrahydrate powder are mixed in a weight ratio of 1.21:1:0.171, then placed in a high-energy ball mill, and ball milled at a speed of 650r / min for 2 hours to obtain whiskers growth precursors;

[0038] (2) Alumina powder, silicon powder, boron carbide powder and BYBSO 2 The low-temperature molten glass powder is fully mixed with a weight ratio of 1:1.75:1.75:2.25 to make a raw material mixture;

[0039] (3) Dilute concentrated phosphoric acid with a concentration of 85% to 60% with water, and place it in a water bath at 85°C, then mix aluminum hydroxide powder into dilute phosphoric acid, wherein the molar ratio of Al:P is 1: 2. Continue mechanical stirring until it becomes a milky white glue solution with a viscosity of 1500mPa·s;

[0040](4) the whisker growth precursor prepared in step (1), the raw material mixture prepared in step (2) and the glue solution prepared in step (3) are placed in a bal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com