Coated pressure sensor based on PDMS material and preparation method thereof

A pressure sensor, wrap-type technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, piezoelectric/electrostrictive device manufacturing/assembly, electrical components, etc. The problems of ductility and wearing comfort, high preparation cost of energy-consuming materials, low detection sensitivity and low detection, etc., are beneficial to macro-scale preparation, good stability and dynamic response, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

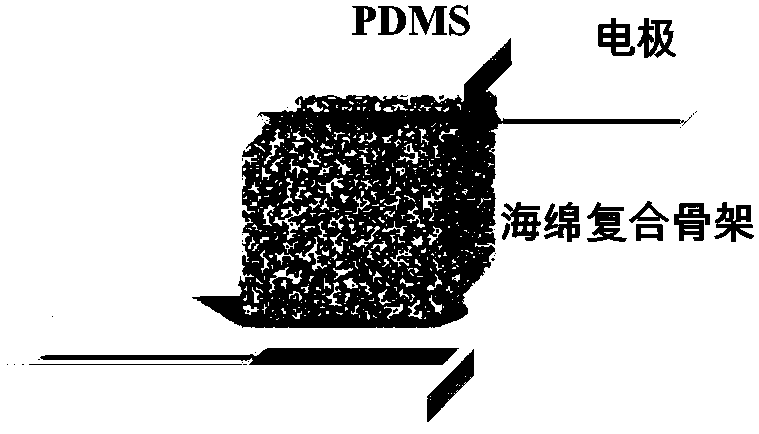

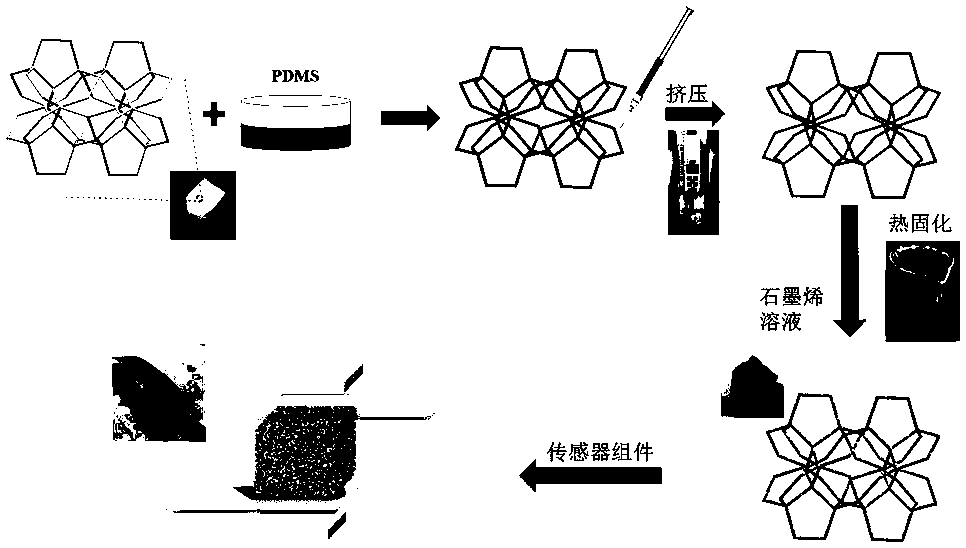

[0040] Such as figure 1 with figure 2 As shown, the present invention belongs to the field of flexible tactile sensors, and specifically relates to a high-sensitivity flexible pressure sensor based on a PDMS-coated three-dimensional structure and a preparation method thereof, which can be applied to tactile perception in the field of electronic skin.

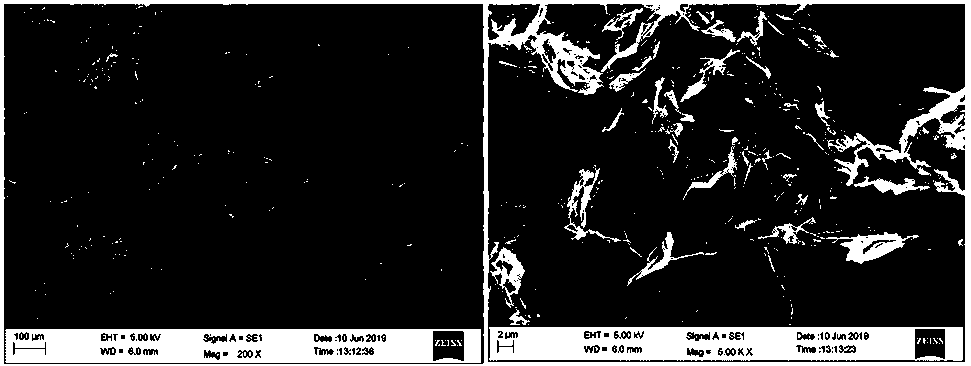

[0041] In order to improve the mechanical properties of the sensor, the present invention uses the three-dimensional skeleton of the sponge as the framework, covers the three-dimensional porous structure with PDMS, uses the characteristics of PDMS to fill the conductive nanomaterials, and self-assembles the three-dimensional structure by adhering electrodes with conductive silver paste to form a flexible sensor. The pressure sensor has the advantages of simple operation and good stability. This type of sensor can provide a feasible solution for the tactile perception of electronic skin in different application scenarios by adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com