Manufacturing method of all-solid-state lithium ion battery

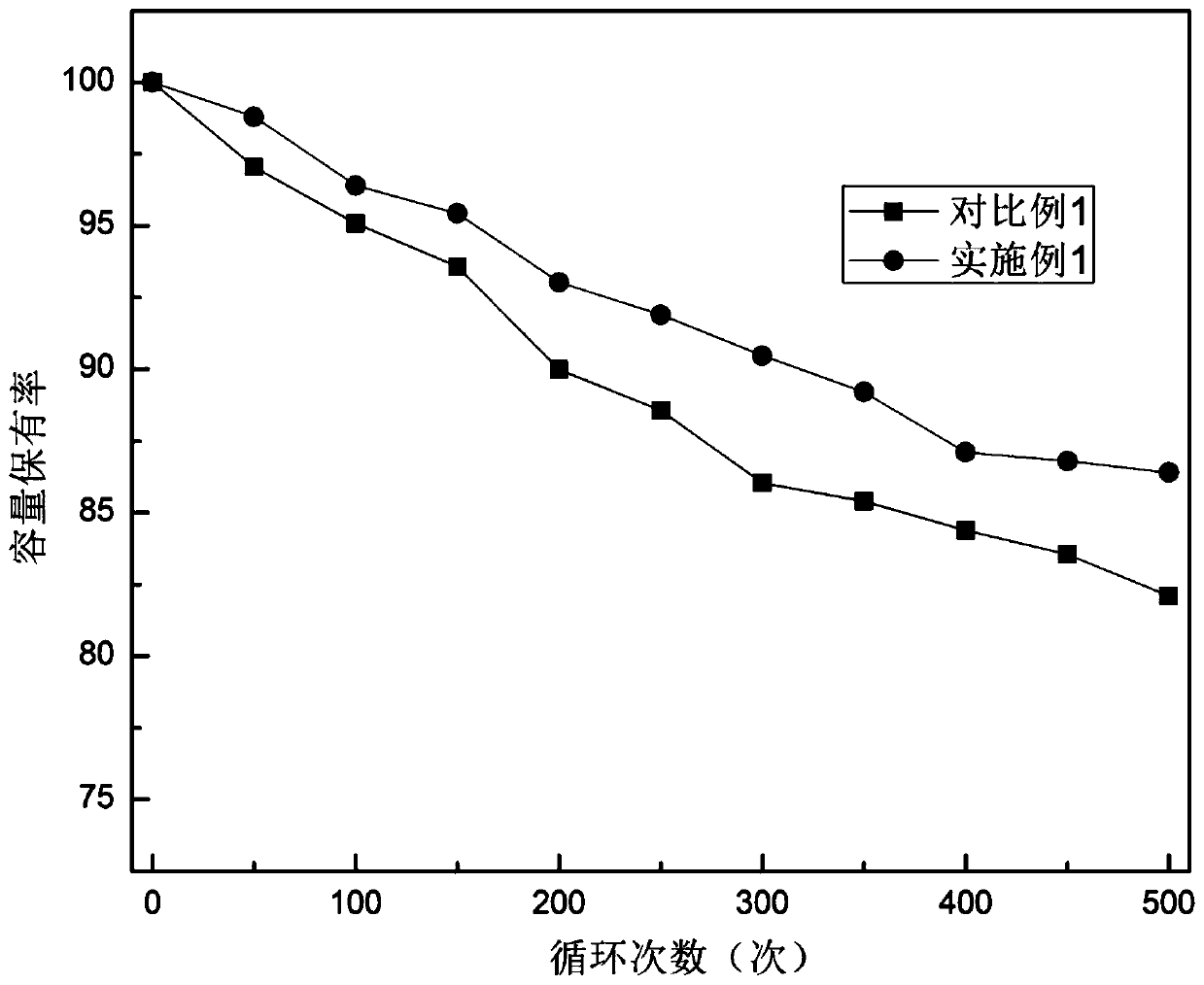

A lithium-ion battery, all-solid-state technology, applied in the direction of battery, electrode manufacturing, secondary battery, etc., can solve the problems of large interface impedance between solid electrolyte/electrode, low ionic conductivity of solid electrolyte, high battery preparation cost, etc., to improve Effects of electrochemical performance, lower internal resistance, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A preparation method of an all-solid-state lithium ion battery, the specific preparation process is as follows:

[0033] Step 1: Weigh LiAlO according to the mass ratio of 50:5:45 2 , Polyvinylidene fluoride, N-methylpyrrolidone, prepared into a solution;

[0034] Step 2: Coating the solution obtained in step 1 on the lithium iron phosphate pole piece, drying, and coating thickness of 5μm;

[0035] Step 3: Weigh Li according to the mass ratio of 50:10:1:4:35 7 La 3 Zr 2 O 12 , LiAlO 2 , Diethylene glycol monoalkyl ether, polyvinylidene fluoride, N-methylpyrrolidone, prepared into a solution;

[0036] Step 4: Coat the solution obtained in step 3 on the pole piece obtained in step 2, and dry it to a coating thickness of 12 μm;

[0037] Step 5: Laminate the pole piece and graphite negative electrode obtained in Step 4 at 85° C., 80 Mpa, and hot pressing for 4 minutes to make a 5Ah soft pack battery.

Embodiment 2

[0039] A preparation method of an all-solid-state lithium ion battery, the specific preparation process is as follows:

[0040] Step 1: Weigh Li according to the mass ratio of 45:5:50 6 MgLa 2 Ta 2 O 12 , Polytetrafluoroethylene, tetrahydrofuran, prepared into a solution;

[0041] Step 2: Coat the solution obtained in step 1 on the lithium nickel cobalt manganate 523 pole piece, and dry it to a thickness of 8 μm;

[0042] Step 3: Weigh Li according to the mass ratio of 45:8:1.5:5:40.5 1.3 Al 0.3 Ti 1.7 (PO 4 ) 3 , Li 6 MgLa 2 Ta 2 O 12 , Diethylene glycol monoalkyl ether, polytetrafluoroethylene, tetrahydrofuran, prepared into a solution;

[0043] Step 4: Coat the solution obtained in step 3 on the pole piece obtained in step 2, and dry it to a coating thickness of 10 μm;

[0044] Step 5: Laminate the pole piece and graphite negative electrode obtained in Step 4 at 85° C., 80 Mpa, and hot pressing for 4 minutes to make a 5Ah soft pack battery.

Embodiment 3

[0046] A preparation method of an all-solid-state lithium ion battery, the specific preparation process is as follows:

[0047] Step 1: Weigh Li according to the mass ratio of 40:8:52 6 BaLa 2 Ta 2 O 12 , Polyvinylpyrrolidone, N,N-diethylformamide, prepared into a solution;

[0048] Step 2: Coat the solution obtained in step 1 on the 622 pole piece of lithium nickel cobalt manganate, dry, and the coating thickness is 10 μm;

[0049] Step 3: Weigh Li according to the mass ratio 40:6:2:6:46 7 La 3 Sn 2 O 12 , Li 6 BaLa 2 Ta 2 O 12 , Propylene glycol monoalkyl ether, polyvinylpyrrolidone, N,N-diethylformamide, prepared into a solution;

[0050] Step 4: Coat the solution obtained in step 3 on the pole piece obtained in step 2, and dry it to a coating thickness of 15 μm;

[0051] Step 5: Laminate the pole piece and graphite negative electrode obtained in Step 4 at 85° C., 80 Mpa, and hot pressing for 4 minutes to make a 5Ah soft pack battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com