A kind of preparation method of rutile phase titanium dioxide/graphene film

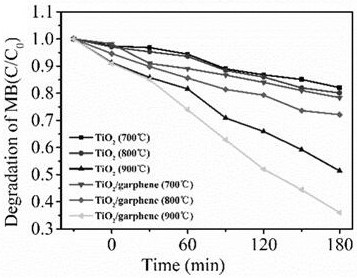

A technology of graphene film and titanium dioxide, applied in the field of photocatalytic materials, to achieve large adsorption and photocatalytic reaction surface area, high photodegradation rate, and improve photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

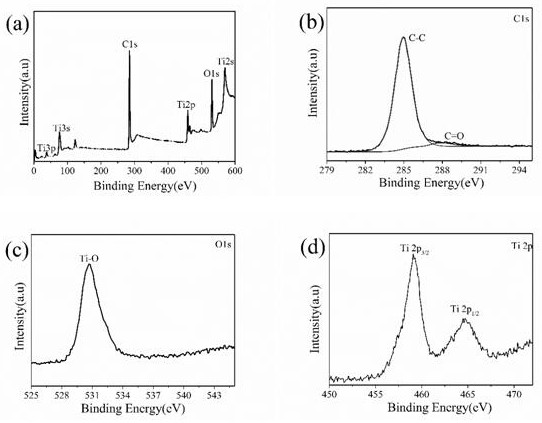

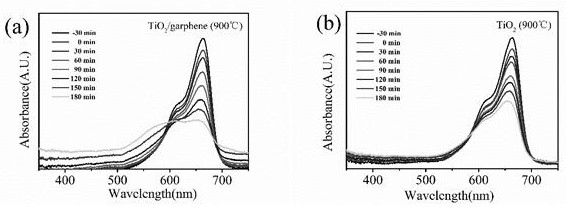

[0025] TiO 2 and TiO 2 / Preparation of graphene film

[0026] 1×1 cm by low-pressure chemical vapor deposition (CVD) 2 Graphene thin films were prepared on copper substrates. Subsequent preparation of TiO by sol-gel method 2 and TiO 2 / graphene film. First, add 20 ml of tetrabutyl titanate into 15 ml of absolute ethanol and mix and stir for 1 hour to form A solution; then add 1.8 ml of acetylacetone and 2 ml of deionized water into 15 ml of absolute ethanol and mix and stir for 1 hours to form B solution; then, slowly inject B solution into A solution, stir at room temperature for 1 hour, and age in an oven at 60 °C to obtain TiO 2 Sol; Finally, spin-coat 4 layers of TiO repeatedly at a speed of 4000 rpm for 15 seconds on Cu substrates without graphene film layer and with graphene film layer respectively. 2 Sol, each spin-coated layer, dried in an oven at 110°C for 15 minutes, then placed the sample in an Ar gas atmosphere with a flow rate of 200 sccm, and annealed at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com