Concrete repairing agent and preparation method thereof

A concrete repairing agent and repairing agent technology, applied in the field of concrete repairing, can solve the problems of fast aging speed, long curing time, reducing the viscosity of epoxy resin, etc. The effect of surface tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

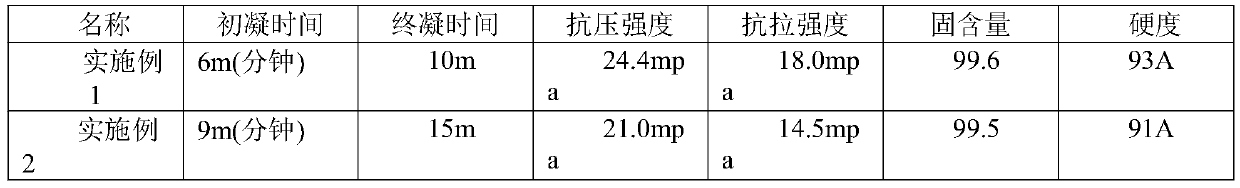

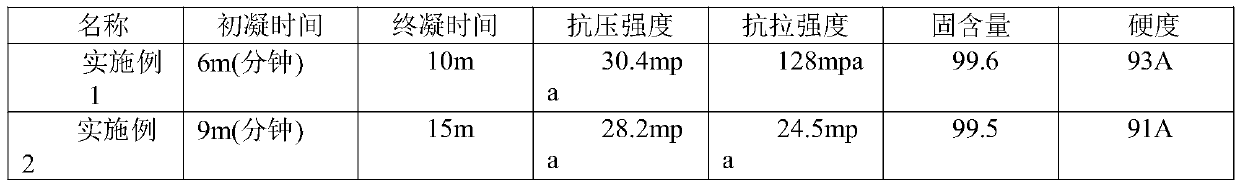

Embodiment 1

[0023] A concrete repair agent and a preparation method thereof, the repair agent is composed of A component and B component with a mass ratio of 1:1; wherein, in parts by mass, A component includes polymethylene polyphenyl isocyanate 66 parts, 34 parts of surfactant, 60 parts of defoamer; B component includes 33 parts of N,N,N,N,-tetra(2-hydroxypropyl)ethylenediamine, 7 parts of polyether polyol, fat 4 parts of alcohol polyoxyethylene ether, 55 parts of surfactant, a little pigment.

[0024] The preparation method of described concrete repair agent, comprises the steps:

[0025] (1) Put the polymethylene polyphenyl isocyanate of above-mentioned mass parts into reactor, add surfactant, antifoaming agent and stir in reactor after the cooling is stable, make component A, in component A Polymethylene polyphenylisocyanate and surfactant have excellent dilution ability, do not prolong crosslinking time, and have no irritating odor;

[0026] (2) Mix and stir the above-mentioned N,...

Embodiment 2

[0029] A concrete repair agent and a preparation method thereof, the repair agent is composed of A component and B component with a mass ratio of 1:1; wherein, in parts by mass, A component includes polymethylene polyphenyl isocyanate 65 parts, 35 parts of surfactant, 60 parts of defoamer; B component includes 33 parts of N,N,N,N,-tetra(2-hydroxypropyl)ethylenediamine, 7 parts of polyether polyol, fat 4 parts of alcohol polyoxyethylene ether, 55 parts of surfactant, a little pigment.

[0030] The preparation method of described concrete repair agent, comprises the steps:

[0031] (1) Put the polymethylene polyphenyl isocyanate of above-mentioned mass parts into reactor, add surfactant, antifoaming agent and stir in reactor after the cooling is stable, make component A, in component A Polymethylene polyphenylisocyanate and surfactant have excellent dilution ability, do not prolong crosslinking time, and have no irritating odor;

[0032] (2) Mix and stir the above-mentioned N,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com