A kind of non-curing polyurethane waterproof coating and preparation method thereof

A polyurethane waterproof, non-curing technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of generating asphalt smoke, complex production process, complex single component, etc., to improve quality, good bonding performance, Good self-healing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

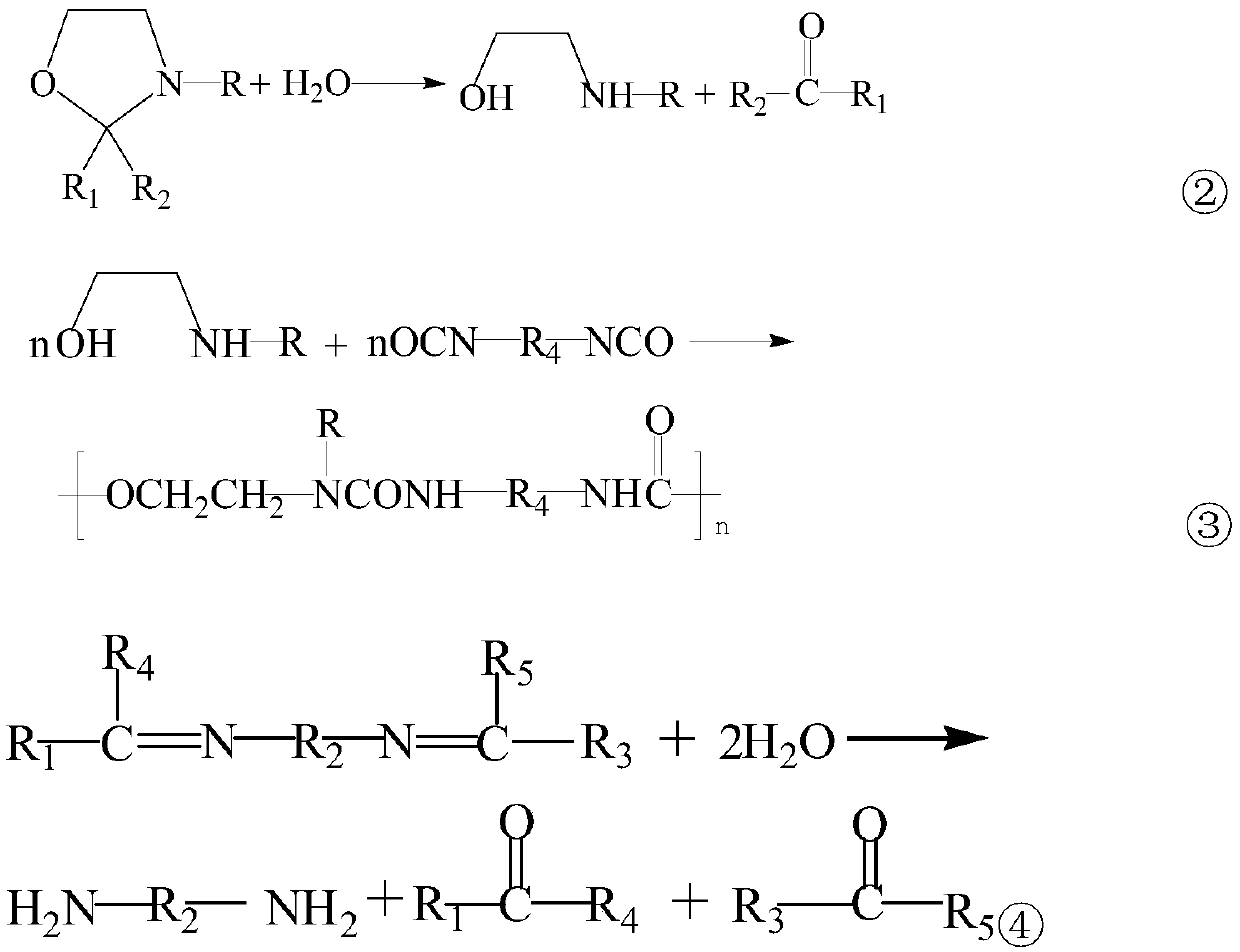

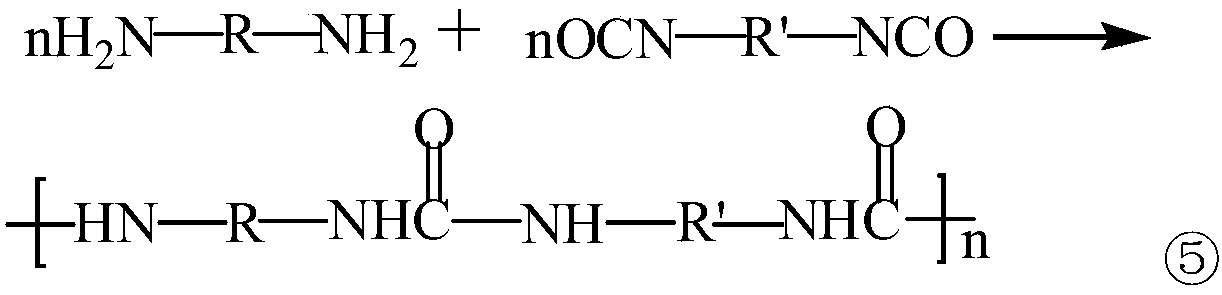

Method used

Image

Examples

Embodiment 1

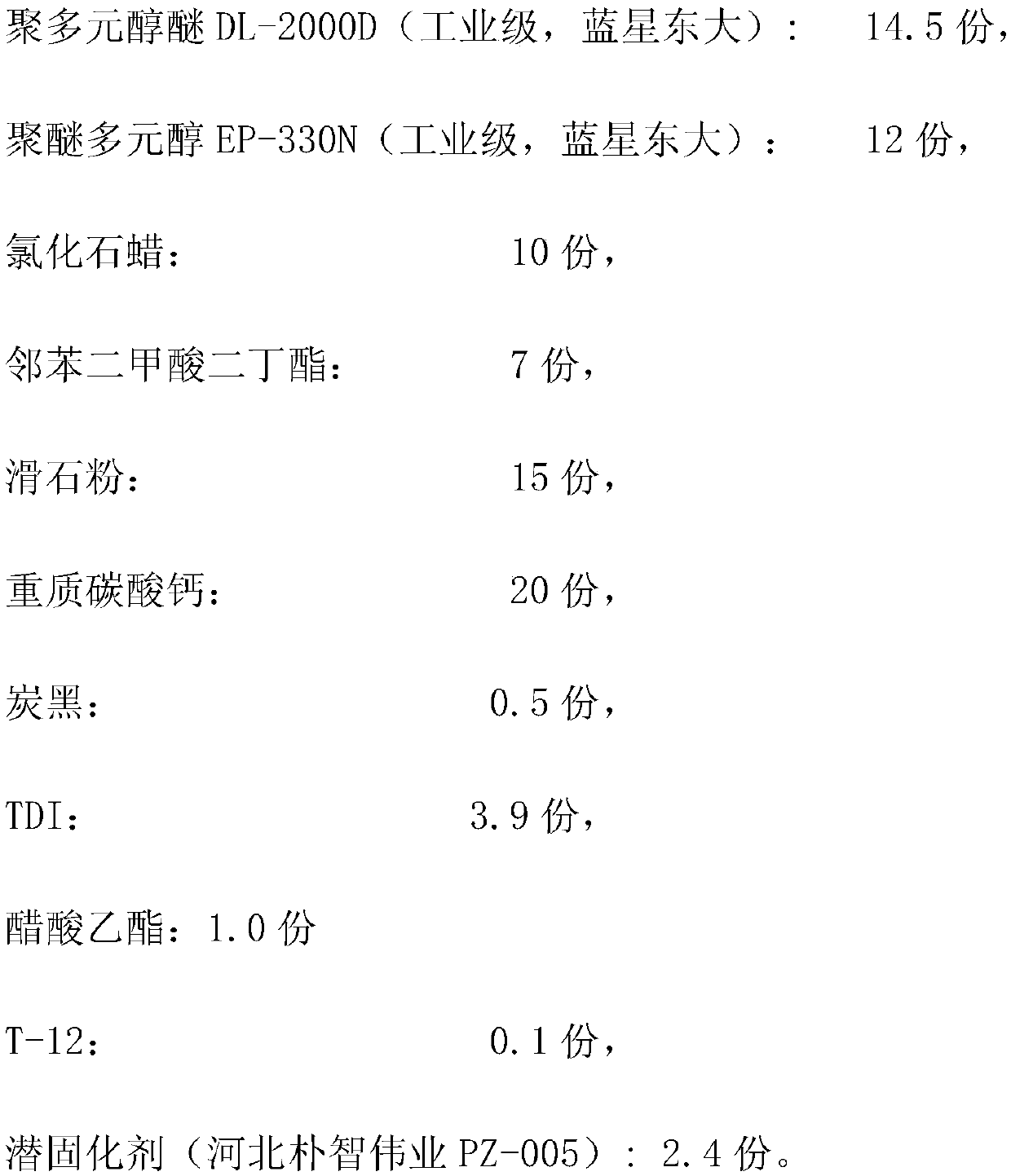

[0026] 1. Formula of non-curing polyurethane waterproof coating

[0027]

[0028] 2. Preparation of non-curing polyurethane waterproof coating

[0029] Put polyol ether DL-2000D, polyether polyol EP-330N, chlorinated paraffin, dibutyl phthalate, talcum powder, heavy calcium carbonate, and carbon black into the reaction kettle, at 120℃±5℃ , Vacuum degree below -0.095MPa and dehydration for 2h, then lower the temperature to 75°C-80°C, add TDI and ethyl acetate, heat up to 80°C±5°C for 2.5h, then add T-12 and react at 80°C±5°C for 0.5 h, then lower the temperature to 75°C-80°C and add latent curing agent, react at 75°C-80°C for 1 hour, and finally lower the temperature to below 70°C for packaging. .

[0030] Table 1-Example 1 prepared non-cured polyurethane waterproof coating key item test results

[0031]

Embodiment 2

[0033] 1. Formula of non-curing polyurethane waterproof coating

[0034]

[0035]

[0036] 2. Preparation of non-curing polyurethane waterproof coating

[0037] Put polyol ether DL-2000D, polyether polyol EP-330N, chlorinated paraffin, talcum powder, heavy calcium carbonate, kaolin, iron oxide red into the reactor, at 120℃±5℃, vacuum degree -0.095 Dehydration below MPa for 2h, lower the temperature to 75°C-80°C0°C, add TDI and acetone, raise the temperature to 80°C±5°C for 2.5h, then add T-12 and react at 80°C±5°C for 0.5h, then cool down to 75 Add latent curing agent at ℃-80℃, react at 75℃-80℃ for 1h, cool down to 65℃, add PZ-005, keep at 75℃-80℃ for 0.5h, and finally cool down to below 70℃ for discharging and packaging.

[0038] Table 2-Example 2 prepared non-cured polyurethane waterproof coating key item test results

[0039]

Embodiment 3

[0041] 1. Formula of non-curing polyurethane waterproof coating

[0042]

[0043] 2. Preparation of non-curing polyurethane waterproof coating

[0044]Put polyol ether DL-1000D, polyether polyol DL-2000D, polyether polyol EP-330N, dioctyl phthalate, talcum powder, heavy calcium carbonate, light calcium carbonate, and green pulp into the reaction In the still, dehydrate at 120°C±5°C, vacuum degree below -0.095MPa for 2h, cool down to 75°C-800°C, add MDI, heat up to 80°C±5°C for 2.5h, then add T-9 at 80°C± React at 5°C for 0.5h, then cool down to 75°C-80°C and add latent curing agent, react at 75°C-80°C for 1h, and finally cool down to below 70°C for discharge and packaging.

[0045] Table 3-Example 3 prepared non-cured polyurethane waterproof coating key item test results

[0046]

[0047] Take the non-curing one-component polyurethane waterproof coating that embodiment 2 makes as an example to detect, and the results are shown in Table 4:

[0048] Table 4-non-curing p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com