Solvent-free winding cyanate ester resin system as well as preparation method and application thereof

A cyanate ester resin and solvent-free technology, which is applied in the field of cyanate resin, can solve the problems of poor paving property of prepreg, high crosslinking density, construction environment pollution, etc., achieve excellent comprehensive mechanical properties, simple preparation process, The effect of good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0066] According to the present invention, the preparation method of this cyanate resin system comprises the following steps:

[0067] Step 1, mixing the cyanate resin with a modifier to obtain a mixture;

[0068] Step 2, adding a catalyst to the mixture.

[0069] According to the present invention, in step 1, mixing the cyanate resin with the modifier includes: heating the cyanate resin, and then mixing with the modifier.

[0070] According to the present invention, in step 1, take cyanate ester and modifier according to the weight ratio of cyanate ester described in the first aspect of the present invention and modifier.

[0071] According to the present invention, the conditions for heating the cyanate resin are: the heating temperature is 50-80°C, preferably 60-70°C; the heating time is 20-80min, more preferably 30-60min.

[0072] In the present invention, heating the cyanate resin can convert the cyanate resin from solid or semi-solid to a viscous fluid state, thereby b...

Embodiment 1

[0099]Take 55g of bisphenol A cyanate resin with a degree of polymerization of 300, heat it at 60°C for 30 minutes, then stir and mix with 45g of bisphenol E cyanate, the stirring speed is 3000r / min, and the stirring time is 30min to obtain a mixture;

[0100] Add 3g zinc acetylacetonate three times in the mixture, stir evenly, interval 5min between every two times, stirring speed is 3000r / min, stirring time is 30min, obtains cyanate resin system, stores for subsequent use.

Embodiment 2

[0102] Take 55g of bisphenol A cyanate resin with a polymerization degree of 300, heat it at 70°C for 30min, then stir and mix it with 50g of bisphenol E cyanate, the stirring speed is 3200r / min, and the stirring time is 30min to obtain the mixture;

[0103] In the mixture, add 3g zinc acetylacetonate three times, stir evenly, interval 5min between every two times, stirring speed is 3500r / min, stirring time is 30min, obtains cyanate resin system, stores for subsequent use.

PUM

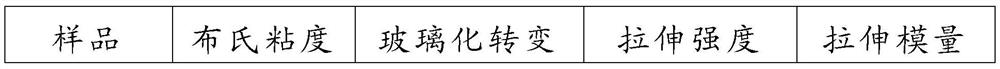

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com