Preparation method of heterocyclic aramid 1313 fiber

A technology of heterocyclic aramid and fiber, which is applied in the field of preparation of heterocyclic aramid 1313 fiber, which can solve the problems of less research on the modification of aramid 1313 fiber, and achieve the effect of improving mechanical strength and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

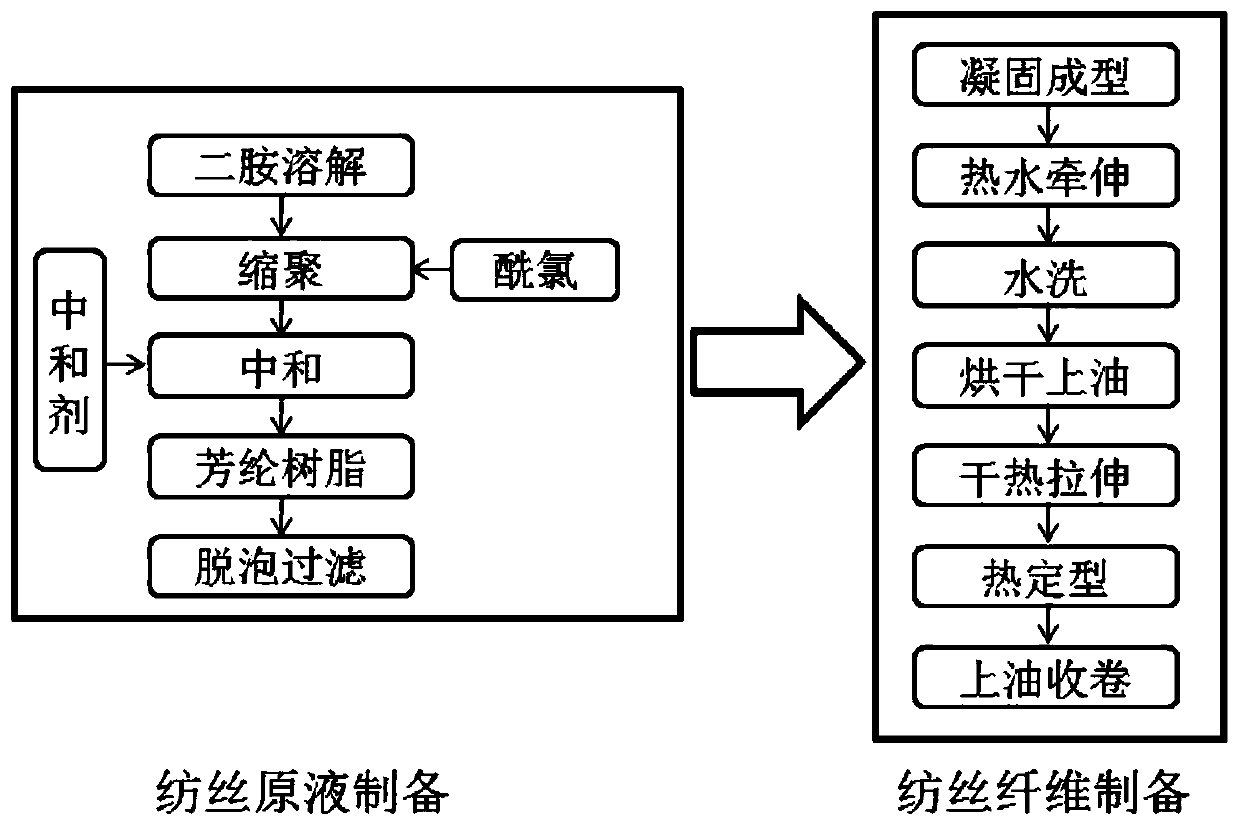

[0038] A kind of preparation method of heterocyclic aramid fiber 1313 fiber of the present invention, its technological process schematic diagram is as figure 1 shown, including the following steps:

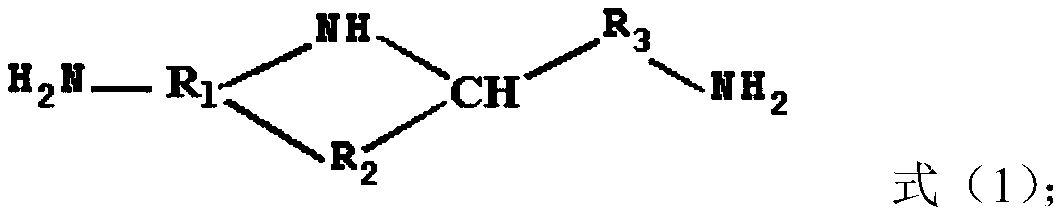

[0039] (1) Dissolve m-phenylenediamine and 5(6)-amino-2-(p-aminophenyl)benzimidazole in N,N-dimethylacetamide containing lithium chloride, the mass of lithium chloride 5% of the mass of N,N-dimethylacetamide to obtain a mixed solution, the temperature of the mixed solution is lowered to -15°C; according to diamine (including m-phenylenediamine and 5(6)-amino-2-( The molar ratio of p-aminophenyl) benzimidazole) and isophthaloyl chloride is 1:1.03, and the molar weight of 5(6)-amino-2-(p-aminophenyl) benzimidazole is isophthaloyl 5% of the molar weight of acid chloride, mix the mixed solution with molten isophthaloyl chloride at 20°C to obtain a heterocyclic aramid 1313 solution containing hydrogen chloride, and the content of the copolymerized modified aramid 1313 resin in this s...

Embodiment 2

[0044] A kind of preparation method of heterocyclic aramid fiber 1313 fiber of the present invention, its technological process schematic diagram is as figure 1 shown, including the following steps:

[0045] (1) m-phenylenediamine and 5(6)-amino-2-(p-aminophenyl) benzimidazole are dissolved in N,N-dimethylacetamide of lithium chloride, and the quality of lithium chloride is 5% of the mass of N,N-dimethylacetamide to obtain a mixed solution, the temperature of the mixed solution was lowered to -20°C; The molar ratio of aminophenyl) benzimidazole) and isophthaloyl dichloride is 1:1.02, and the molar weight of 5(6)-amino-2-(p-aminophenyl) benzimidazole is isophthaloyl dichloride 10% of the molar weight, mix and react the mixed solution with molten isophthaloyl chloride at 10°C to obtain a heterocyclic aramid 1313 solution containing hydrogen chloride, and the content of the copolymerized modified aramid 1313 resin in this solution is 14.5% , the logarithmic viscosity is 2.75; ...

Embodiment 3

[0050] A kind of preparation method of heterocyclic aramid fiber 1313 fiber of the present invention, its technological process schematic diagram is as figure 1 shown, including the following steps:

[0051] (1) m-phenylenediamine and 5(6)-amino-2-(p-aminophenyl) benzimidazole are dissolved in N,N-dimethylacetamide of lithium chloride, and the quality of lithium chloride is 6% of the mass of N,N-dimethylacetamide to obtain a mixed solution, the temperature of the mixed solution was lowered to -15°C; The molar ratio of aminophenyl) benzimidazole) and isophthaloyl dichloride is 1:1.02, and the molar weight of 5(6)-amino-2-(p-aminophenyl) benzimidazole is isophthaloyl dichloride 20% of the molar weight, mix the mixed solution with molten isophthaloyl chloride at 15°C to obtain a heterocyclic aramid 1313 solution containing hydrogen chloride, and the content of the copolymerized modified aramid 1313 resin in this solution is 12.5% , the logarithmic viscosity is 2.05;

[0052] (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com