Method for solidifying island reef calcareous sand through indigenous microorganisms

A microbial and calcareous technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of high preparation and preservation costs of exogenous microorganisms, difficult to ignore marine ecological impact, limited freshwater resources on islands and reefs, etc. Proliferation of native urease microorganisms, avoidance of adverse effects, reduced permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In this case, a method for solidifying calcareous sand on island reefs using native microorganisms, the method includes the following steps:

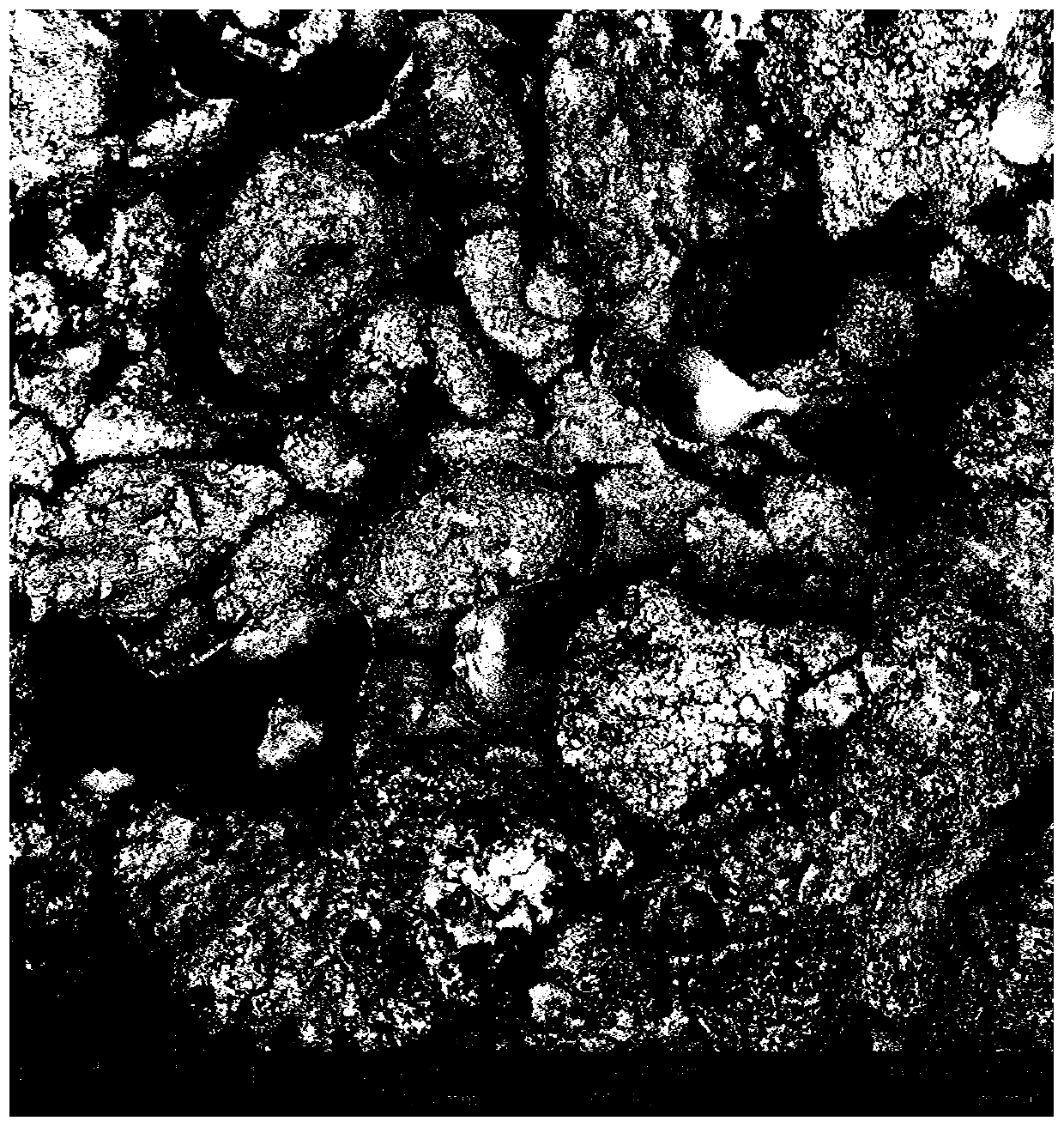

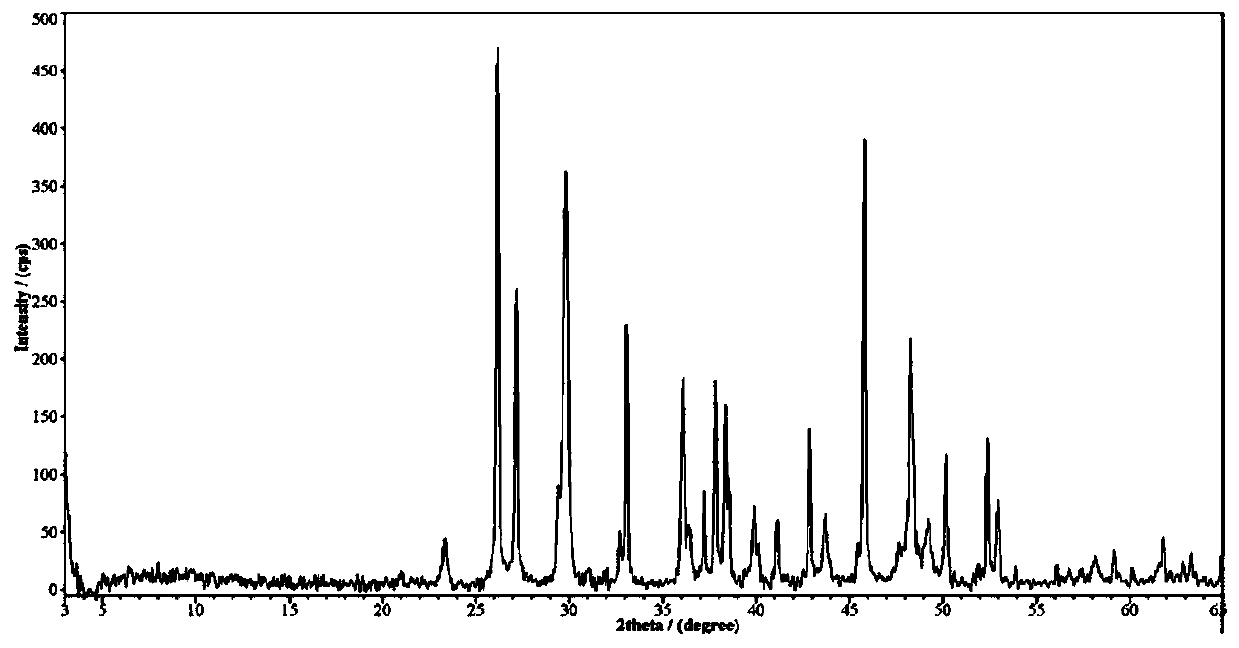

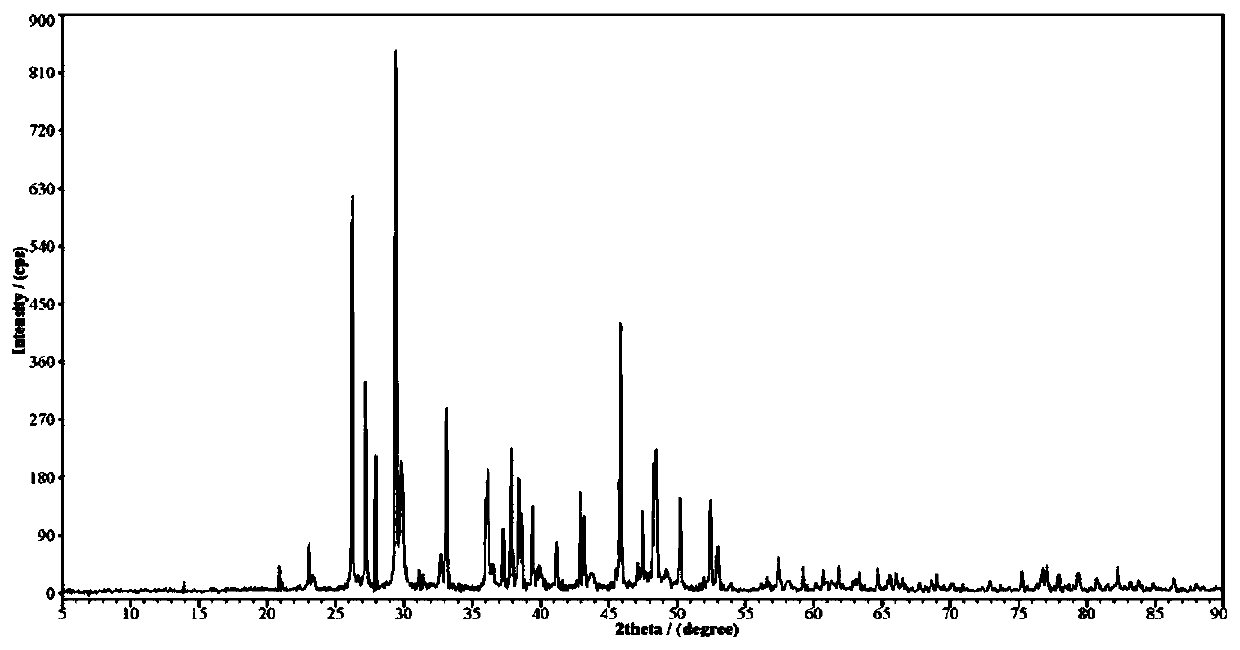

[0026] (1) Calcareous sand samples were aseptically collected at a depth of 0.5m from a certain island in the South China Sea, and the calculated porosity was 0.45; at the same time, a small amount of calcareous sand samples were dried, and X-ray diffraction tests were performed on the dried calcareous sand.

[0027] (2) preparation of growth-promoting liquid and cementing liquid, the formula of the growth-promoting liquid adopted in the present embodiment is: urea 0.5mol / L, sodium acetate 0.035mol / L, ammonium chloride 0.0125mol / L, yeast extract 0.3g / L L; The formula of cementing fluid used in this example is: 0.5 mol / L urea, 0.035 mol / L sodium acetate, 0.0125 mol / L ammonium chloride, 0.3 g / L yeast extract, and 0.40 mol / L calcium chloride.

[0028] (3) Fill a plexiglass tube with a length of 10 cm and an inner diameter of 5 cm wi...

Embodiment 2

[0036] The steps in this embodiment are basically the same as those in Example 1, except that the formulas of the growth-promoting liquid and the cementing liquid are different in step (2), and the formula of the growth-promoting liquid in this embodiment is: urea 0.3mol / L, sodium acetate 0.045mol / L, ammonium chloride 0.01mol / L, yeast extract 0.1g / L; the cementing liquid formula used in this example is: urea 0.3mol / L, sodium acetate 0.045mol / L, ammonium chloride 0.01mol / L, yeast extract 0.1g / L, calcium chloride 0.25mol / L.

[0037] The value of the unconfined compressive strength of the cured body measured in this embodiment is 1.10 Mpa.

Embodiment 3

[0039]The steps in this embodiment are basically the same as those in Example 1, except that the formulas of the growth-promoting liquid and the cementing liquid are different in step (2), and the formula of the growth-promoting liquid in this embodiment is: urea 0.4mol / L, sodium acetate 0.04mol / L, ammonium chloride 0.011mol / L, yeast extract 0.2g / L; the cementing fluid formula used in this example is: urea 0.4mol / L, sodium acetate 0.04mol / L, ammonium chloride 0.011mol / L, yeast extract 0.2g / L, calcium chloride 0.35mol / L.

[0040] The value of the unconfined compressive strength of the cured body measured in this embodiment is 1.21Mpa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

| Unconfined compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com