Ohmic contact forming method for (100) oriented n-type monocrystalline diamond electrode

A single crystal diamond, ohmic contact technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of high contact resistivity and difficult ohmic preparation, and achieve lower specific contact resistivity, lower requirements, and good ohmic contact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

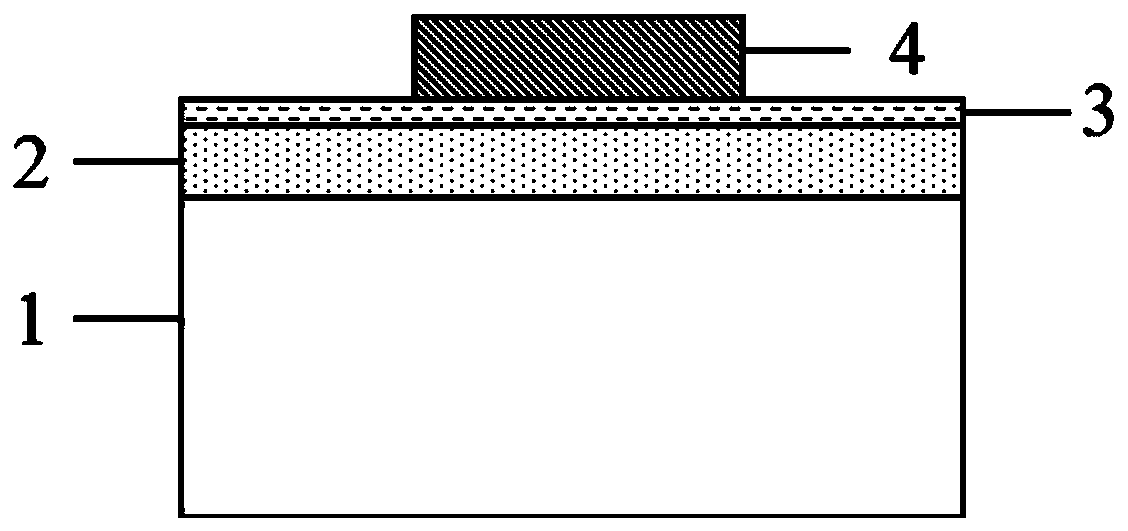

[0031] like figure 1 , a (100) oriented n-type single crystal diamond electrode ohmic contact forming method, (100) oriented n-type single crystal diamond 1 is a self-supporting body material with a size of 3 × 3 × 0.3mm 3 , with a surface roughness of 1 nm. A 10nm-thick n-type diamond epitaxial thin layer 2 was epitaxially grown on its surface by MPCVD, and the growth conditions were: air pressure 100 Torr, gas flow rate 500 sccm, CH 4 / H 2 = 1%, PH 3 / CH 4 =0.1%, and the substrate temperature was 900°C. After the growth, the sample was placed in a 1:1 mixture of sulfuric acid and nitric acid, heated at 250 °C for 1 h to convert the surface hydrogen terminals into oxygen terminals, and annealed at 900 °C for 5 min to obtain high conductivity Table 3. Through photolithography, magnetron sputtering, and lift-off processes, W metal electrodes 4 are prepared on the highly conductive surface 3, and then annealed at 400° C. for 10 minutes in an argon atmosphere to form ohmic c...

Embodiment 2

[0033] like figure 1 , a (100) orientation n-type single crystal diamond electrode ohmic contact forming method, (100) orientation n-type single crystal diamond 1 is a single crystal thin film, the size is 10 × 10 × 0.001mm 3 , with a surface roughness of 2nm. The n-type diamond epitaxial thin layer 2 with a thickness of 100nm is epitaxially grown on its surface by MPCVD method, and the growth conditions are: air pressure 100Torr, gas flow rate 500sccm, CH 4 / H 2 = 1%, PH 3 / CH 4 = 1%, and the substrate temperature was 900°C. After the growth, the surface hydrogen terminals were converted to oxygen terminals by ultraviolet ozone treatment, and annealed at 1100°C for 5 minutes to obtain high conductivity Table 3. Ti / Pt / Au metal electrodes 4 are prepared on the highly conductive surface 3 by photolithography, magnetron sputtering, and lift-off processes, and then annealed at 700° C. for 20 minutes in an argon atmosphere to form ohmic contacts.

Embodiment 3

[0035] like figure 1 , a (100) orientation n-type single crystal diamond electrode ohmic contact forming method, (100) orientation n-type single crystal diamond 1 is a self-supporting body material, the size is 5 × 5 × 0.5mm 3 , with a surface roughness of 2nm. A 50nm-thick n-type diamond epitaxial thin layer 2 was epitaxially grown on its surface by MPCVD method, and the growth conditions were: air pressure 100 Torr, gas flow rate 500 sccm, CH 4 / H 2 = 1%, PH 3 / CH 4 =0.5%, and the substrate temperature was 900°C. After the growth, the sample was placed in a 1:1 mixture of sulfuric acid and nitric acid, heated at 250 °C for 1 h to convert the surface hydrogen terminals into oxygen terminals, and annealed at 1000 °C for 10 min to obtain high conductivity Table 3. Through photolithography, magnetron sputtering, and lift-off processes, Ti / Au metal electrodes 4 are prepared on the highly conductive surface 3, and then annealed at 550° C. for 20 minutes in an argon atmosphere...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com