Epoxy-terminated polysulfide rubber modified SBS, preparation method thereof, and application of modified SBS in modified asphalt

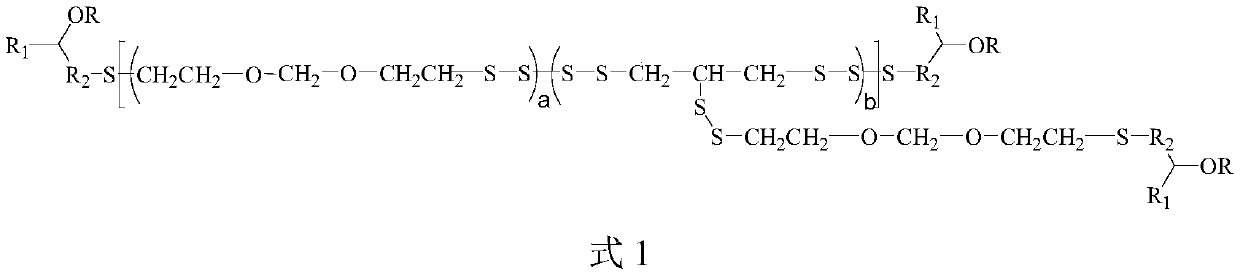

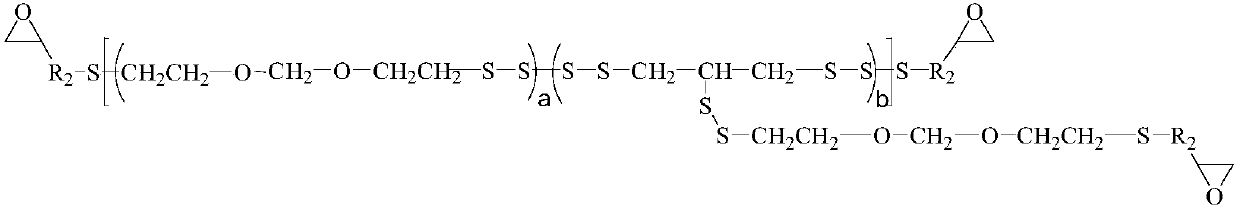

A technology of polysulfide rubber and epoxy-terminated technology, which is applied in the field of modified SBS rubber, can solve the problems that it has not been reported and cannot be used as an anionic polymerization active lithium coupling agent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Add 3500mL of cyclohexane solution of 10% n-hexane in mass fraction to a 5-liter polymerization kettle under the protection of nitrogen, then add 0.2mL tetrahydrofuran, and heat the solvent in the polymerization kettle to 50-60°C with hot water , put 100g of styrene into the polymerization kettle and start stirring, then inject 1.0mol / L n-butyllithium 12mL into the polymerization kettle with a syringe, and react for 20~25min; then add 338 butadiene at 50~90℃ After reacting for 25min; adding the toluene solution mass concentration that is prepared from preparation example (1) again is 50% end epoxy polysulfide rubber solution 10.6g, at 55 ~ After the coupling reaction was carried out at 70°C for 30 minutes. Discharge the polymer, and add 1.25g of antioxidant 1076 into the glue, stir the glue, then add the glue into boiling water and stir for 40 minutes, after the solvent is fully evaporated, filter out the water, and put it at 80°C Bake at low temperature for 2h. That ...

Embodiment 2

[0091] With the relevant process conditions in Example 1 unchanged, only changing the amount of n-butyllithium is 14mL, the amount of butadiene is 580mL, and the mass concentration of the toluene solution prepared in the preparation example (2) is 50%. Epoxy polysulfide rubber solution 34.3g.

[0092] The SBS Mn after coupling was measured to be 8.24×10 4 ,M W =13.34×10 4 ; Melt index 7.9g / 10min; 300% modulus stress of 2.16MPa, elongation at break of 1030% and permanent deformation of 12% were measured after the rubber was pressed into tablets.

Embodiment 3

[0094] With the relevant process conditions in Example 1 unchanged, only changing the amount of n-butyllithium to 10mL, the amount of butadiene to 435mL, and the mass concentration of the toluene solution prepared in Preparation Example (3) to be 50% end Epoxy polysulfide rubber solution 37.5g.

[0095] The SBS Mn after coupling was measured to be 11.73×10 4 ,M W =18.84×10 4 ; Melt index 3.67g / 10min; 300% modulus stress of 2.46MPa, elongation at break of 860% and permanent deformation of 16% were measured after the rubber was pressed into tablets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Stress at modulus | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com