Photothermal conversion device based on hydrophilic carbon felt and application thereof

A light-to-heat conversion and hydrophilic technology, which can be applied to solar collectors in specific environments, solar collectors, and general water supply conservation. It can solve the problems of high cost, heat conduction loss, and poor evaporation effect, and achieve saturation The effect of high vapor pressure and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1—the surface hydrophilic treatment of carbon felt

[0033] The method for surface hydrophilic treatment of the commercialized carbon felt comprises the following steps: placing a commercialized carbon felt with an appropriate size in deionized water, cleaning it ultrasonically for 30 minutes, and then drying it for use. Place the above-mentioned carbon felt in a reaction vessel with an appropriate amount of mass concentration of 60% concentrated nitric acid solution (note: the carbon felt should be completely submerged in concentrated nitric acid), and then seal the reaction vessel. Heat in a water bath at 80°C for 2h to 6h. After cooling to room temperature, rinse the carbon felt with water repeatedly until neutral. Dry the above carbon felt in an oven at 60°C to obtain a hydrophilic carbon felt. By adjusting the heating time, carbon felts with different surface contact angles (60.1°-2.1°) can be obtained. Then cut according to the required size to obtain...

Embodiment 2

[0034] Embodiment 2—the surface hydrophilic treatment of carbon cloth

[0035] The method for surface hydrophilic treatment of commercialized carbon cloth comprises the following steps: arranging commercialized carbon with appropriate size in deionized water, ultrasonic cleaning for 30 minutes, and drying for later use. Arrange the above-mentioned carbon in the concentrated nitric acid solution with an appropriate mass concentration of 60% in the reaction vessel (note: the carbon cloth should be completely submerged in the concentrated nitric acid), and then seal the reaction vessel. Heat in a water bath at 80°C for 2h to 6h. After cooling to room temperature, rinse the carbon cloth with water repeatedly until it becomes neutral. Arrange the above carbon in an oven at 60°C for drying to obtain a hydrophilic carbon cloth. By adjusting the heating time, carbon cloths with different surface contact angles (74.1°-0.1°) can be obtained. Then it is cut according to the required si...

Embodiment 3

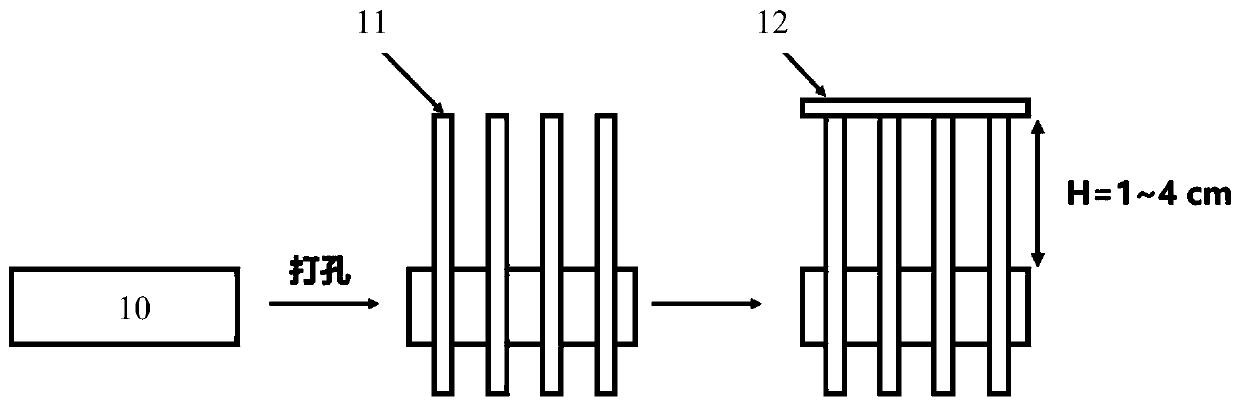

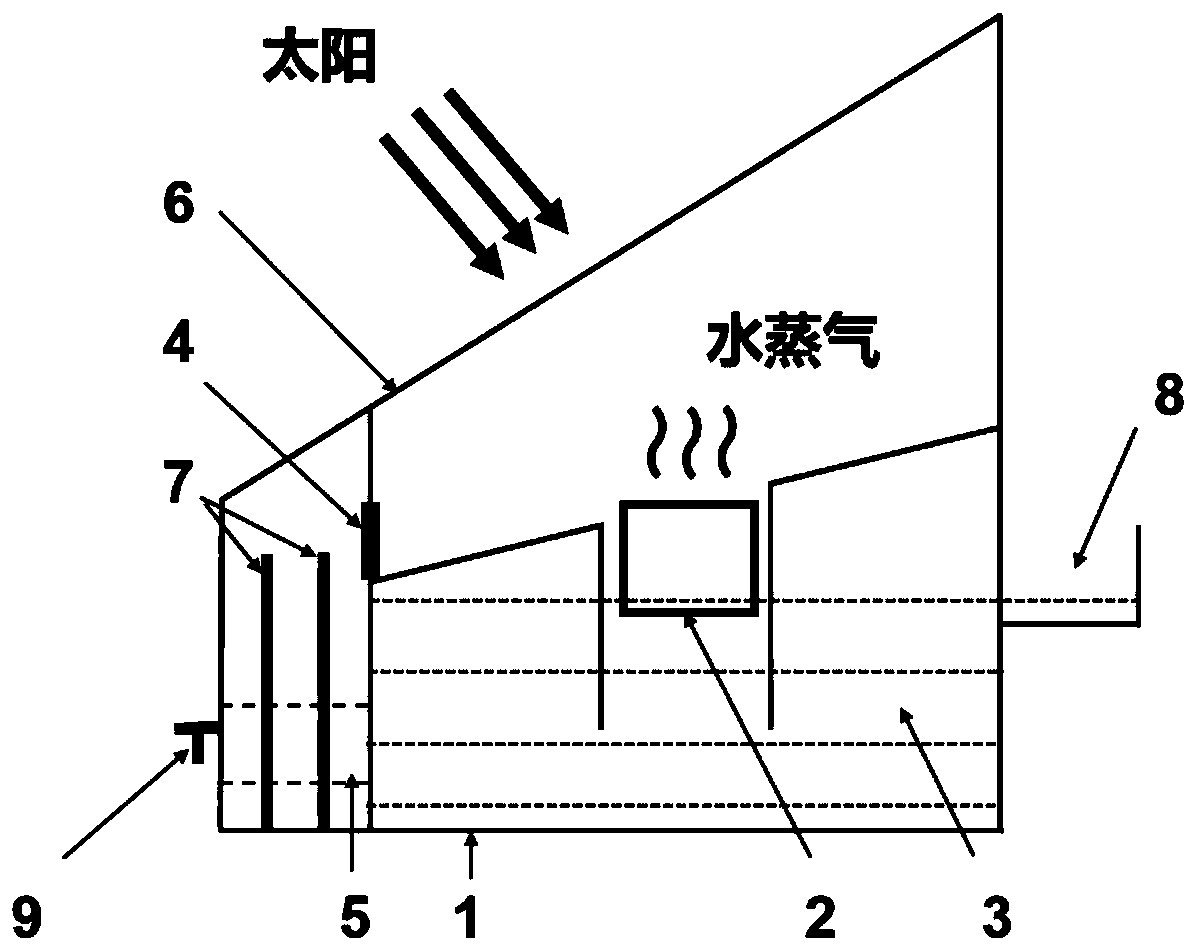

[0036] Example 3—Using hydrophilic carbon felt to construct light-to-heat conversion devices

[0037]The method for constructing the light-to-heat conversion device 3 by using hydrophilic carbon felt, the specific steps are as follows: use a cylindrical polystyrene foam with a radius of 3.5 cm and a thickness of 1 cm as the heat insulating support 10, and evenly open 12 vertical cylinders Shaped channel (radius is consistent with the radius of water transmission body 11), as the support layer for the device to float on the surface of the liquid. The hydrophilic carbon felt or carbon cloth is rolled into a cylindrical hydrophilic carbon felt strip with a radius of 3 mm and a length of 3 cm to 7 cm, and then evenly inserted into the channels to form the water transport body 11 . Both ends of the water transport body 11 protrude from the upper and lower surfaces of the heat-insulating support 10, and the upper section is directly exposed to the air, and the length of the upper se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com