Magnetic ferroferric oxide/graphene oxide nano composite Fenton-like catalytic material, and preparation and application thereof

A ferric tetroxide and nanocomposite technology, applied in metal/metal oxide/metal hydroxide catalysts, oxidized water/sewage treatment, physical/chemical process catalysts, etc. Secondary pollution and other problems, to achieve mild and controllable reaction conditions, improve biodegradability, and reduce toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

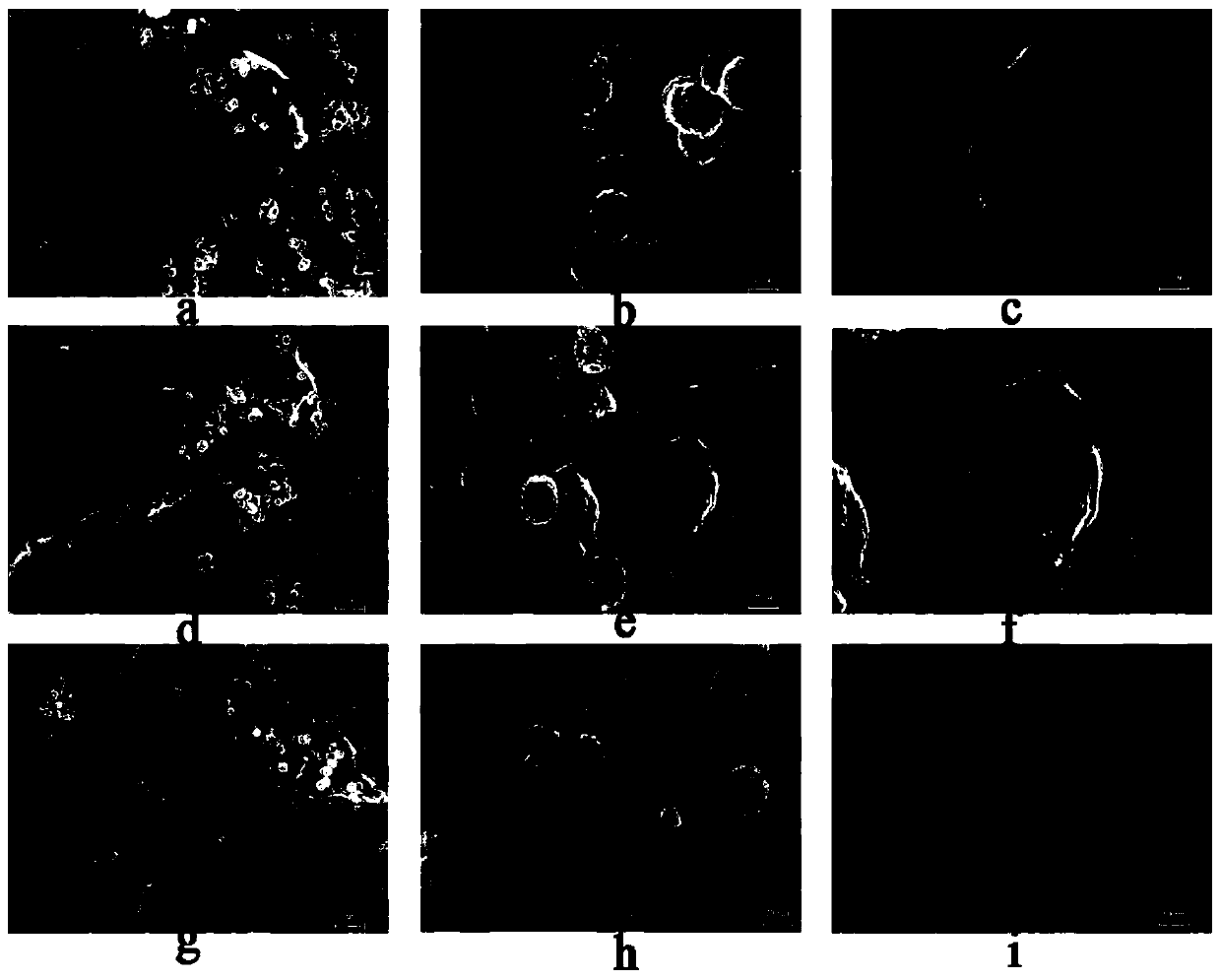

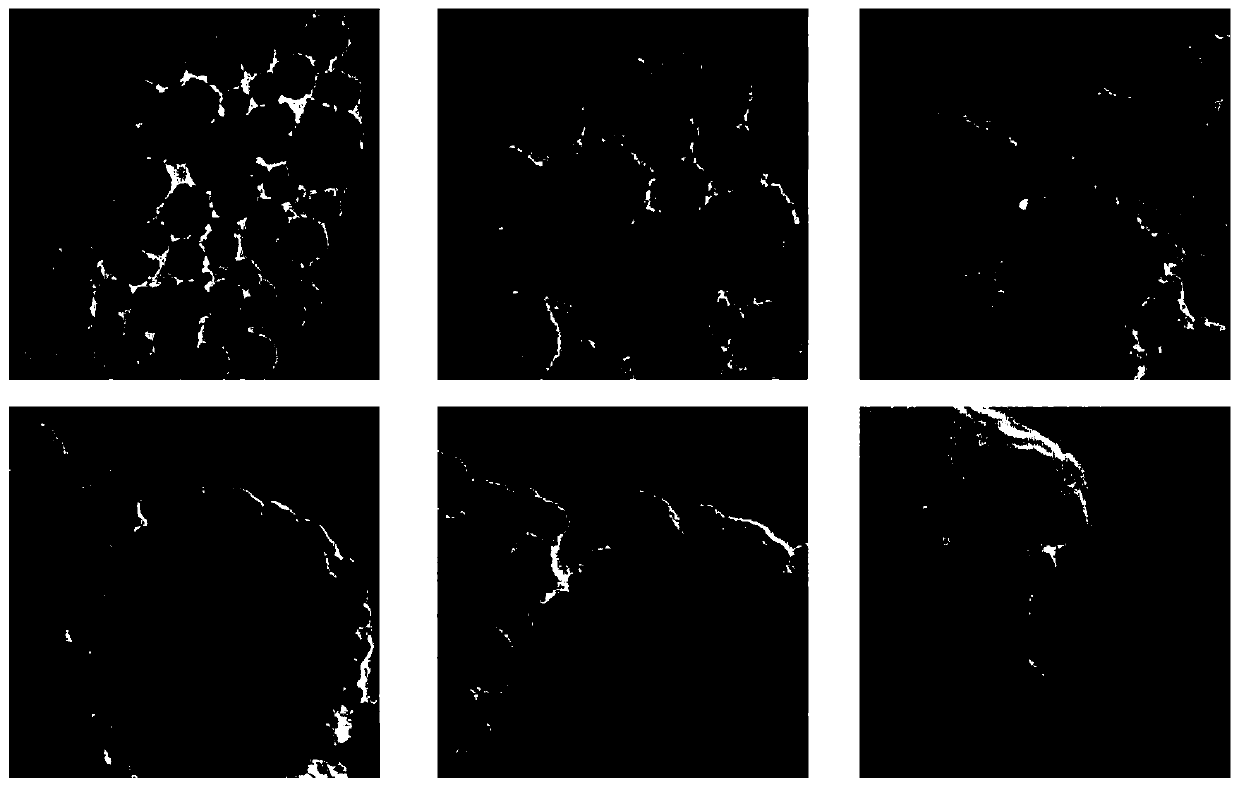

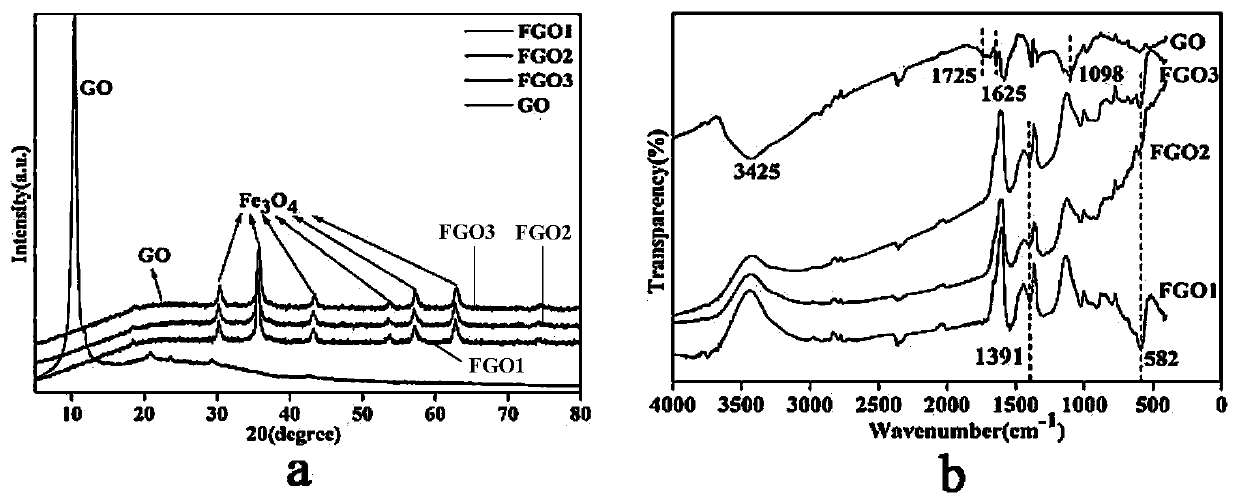

[0034] Preparation Example 1: Preparation of magnetic ferroferric oxide / graphene oxide nanocomposite Fenton-like catalytic material (FGO1)

[0035] (1) Preparation of graphene oxide (GO) by improved Hummers method

[0036] Disperse 3g of graphite powder (325 mesh) in a mixture of 360mL of concentrated sulfuric acid and 40mL of phosphoric acid, and stir rapidly for 1h to disperse the system evenly. Then carefully add 18g of potassium permanganate (potassium permanganate is ground into powder) several times, and this process lasts for 0.5h. Finally, the ice-water bath was continued for another 1 h (the whole process was carried out in the ice-water bath, and rapid stirring was maintained, while ensuring that the system temperature did not exceed 15° C.). Remove the ice-water bath, raise the temperature to about 50°C, react for about 12 hours and cool to room temperature, then add 400mL ice deionized water to the system, continue stirring, the system temperature will rise to abo...

preparation Embodiment 2

[0039] Preparation Example 2: Preparation of magnetic ferroferric oxide / graphene oxide nanocomposite Fenton-like catalytic material (FGO2)

[0040] The difference from Example 1 is that step (2) takes 75 mg of GO, other steps and conditions are the same as in Example 1, and 80.45% Fe 3 o 4 , 19.55% graphene oxide FGO2. Fe in the prepared FGO2 3 o 4 Nano hollow sphere diameter is 200~300nm; FGO2 specific surface area is 70.15m2 / g -1 , the saturation magnetic intensity is 45.52emu·g -1 .

preparation Embodiment 3

[0041] Preparation Example 3: Preparation of magnetic ferroferric oxide / graphene oxide nanocomposite Fenton-like catalytic material (FGO3)

[0042] The difference from Example 1 is that step (2) takes 125 mg of GO, other steps and conditions are the same as in Example 1, and 71.18% Fe 3 o 4 , 28.82% graphene oxide FGO3. Fe in the prepared FGO3 3 o 4 The diameter of hollow nanospheres is 200-300nm; the specific surface area of FGO3 is 86.70m 2 / g -1 , the saturation magnetic intensity is 40.82emu·g -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Saturation magnetic strength | aaaaa | aaaaa |

| Saturation magnetic strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com