Membrane catalyst precursor, membrane catalyst, preparation methods therefor and application of membrane catalyst

A catalyst and precursor technology, applied in the field of membrane catalyst precursors, can solve problems such as rising production costs, and achieve the effects of reducing sintering, dispersing uniformly, and improving catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

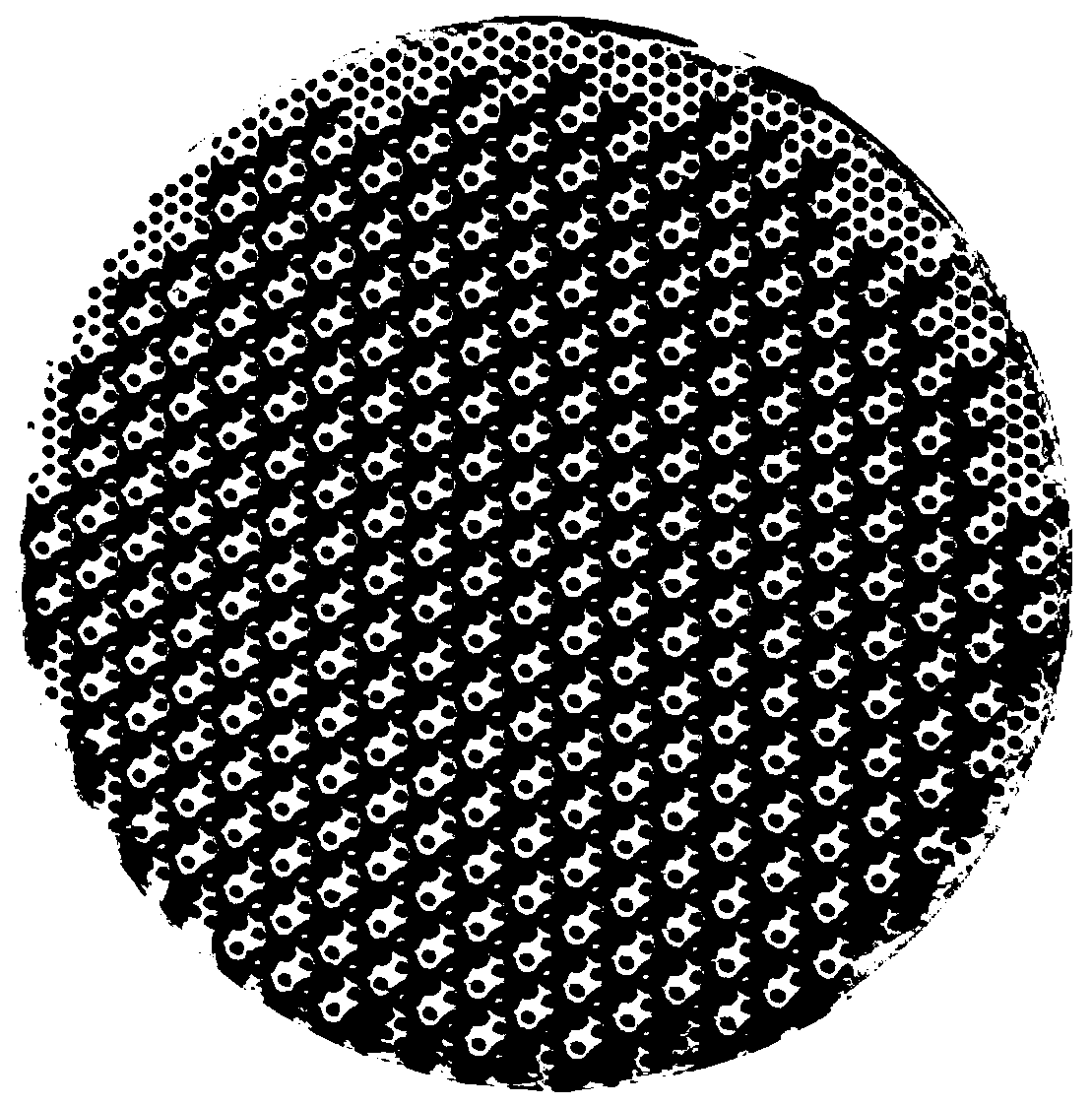

Image

Examples

preparation example Construction

[0049] The embodiment of the present invention provides a Pd / AlF 3 The preparation method of membrane catalyst precursor, comprises the steps:

[0050] S101, under the condition of pH 6.5-7.5, slowly drop an acid solvent into the polar organic solvent to obtain a mixed solvent.

[0051] Wherein, the polar organic solvent can be absolute ethanol, the acid solvent is one of hydrochloric acid, nitric acid or acetic acid, and the mass percentage of the acid solvent is 36%-70%. Preferably, the acid solvent is concentrated nitric acid with a mass percentage of 67%.

[0052] S102, respectively adding aluminum alkoxide, metal promoter salt, chloropalladium acid solution and surfactant to the mixed solvent, and refluxing in a constant temperature water bath at 50-70° C. to obtain a palladium-containing composite sol.

[0053] Wherein, the aluminum alkoxide is aluminum isopropoxide or aluminum butoxide, and the metal promoter salt includes at least two of zinc, chromium, nickel, tin c...

Embodiment 1

[0080] Preparation of palladium-containing composite sol: Slowly add concentrated nitric acid (wt%=67%) dropwise to absolute ethanol and stir evenly, control the pH value to 7.5, then add 100 parts of aluminum isopropoxide (metal mass ratio), 0.5 parts of CrCl 3 (Metal mass ratio), 0.5 parts of ZnCl 2 (Metal mass ratio), 2mL chloropalladium acid solution (palladium concentration: 0.010g / mL), 0.01 mole CTAB (cetyltrimethylammonium bromide), reflux in a constant temperature water bath at 50°C for 10h to obtain a palladium-containing composite sol.

[0081] Pd / AlF 3 Preparation of the composite membrane catalyst: the porous ceramics are placed in the palladium-containing composite sol, impregnated, dried, and roasted, and repeated six times to obtain the membrane catalyst precursor. The membrane catalyst precursor was placed in a 35wt.% HF solution, soaked in a water bath at 50°C for 2h, washed to neutrality, dried in vacuum at 60°C, and H 2 Pd / AlF with Pd loading of 1.2% obtai...

Embodiment 2

[0083] Preparation of palladium-containing composite sol: Slowly add concentrated nitric acid (wt%=67%) dropwise to absolute ethanol and stir evenly, control the pH value to 6.5, then add 100 parts of aluminum isopropoxide (metal mass ratio), 2 parts of NiCl2 (Metal mass ratio), 2.5 parts of ZnCl 2 (Metal mass ratio), 6mL chloropalladium acid solution (palladium concentration: 0.010g / mL), 0.04 mole CTAB (cetyltrimethylammonium bromide), reflux in a constant temperature water bath at 55°C for 15h to obtain a palladium-containing composite sol.

[0084] Pd / AlF 3 Preparation of the composite membrane catalyst: the porous ceramics are placed in the palladium-containing composite sol, impregnated, dried, and roasted, and repeated six times to obtain the membrane catalyst precursor. The membrane catalyst precursor was placed in 35wt.% HF solution, soaked in a 50°C water bath for 0.5h, washed to neutrality, vacuum-dried at 50°C, and H 2 Reduction at 400℃ in atmosphere to obtain Pd / A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com