Production process of 2-keto-L-gulonic acid methyl ester

A technology of methyl guronate and gulon acid, which is applied to the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of large production equipment, high labor intensity, and large consumption of concentrated sulfuric acid. Achieve the effect of reducing the occupied area, reducing the workload of workers and shortening the reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

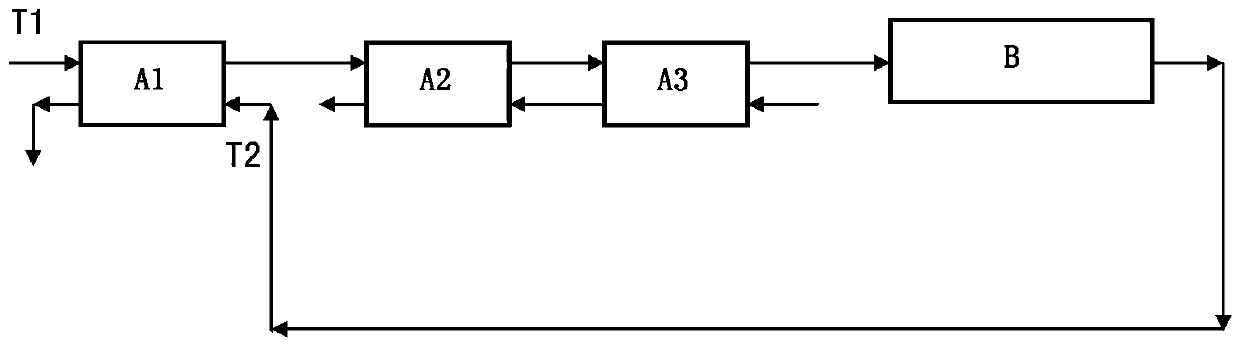

[0023] Production equipment: Three heat exchangers (A1, A2, A3) are used in series to form a feed heat exchanger. After the feed heat exchanger is connected to the tubular reactor B as an esterification reaction device, the material outlet of the tubular reactor B is The heat medium inlet of the primary heat exchanger formed by the countercurrent flow setting of the first heat exchanger A1 before the feed heat exchanger is connected, and the heat medium outlet of the primary heat exchanger of the feed heat exchanger is used as the production of 2-keto-L -The outlet of methyl guronate equipment, the last two heat exchangers (A2, A3) of the feed heat exchanger are connected in series and each heat exchanger is the second stage of the feed heat exchanger composed of countercurrent flow combination The heat exchanger adopts an external heat source;

[0024] Specific operation:

[0025] In the batching tank, add 2-keto-L-gulonic acid and methanol according to the mass volume ratio...

Embodiment 2

[0027] Production equipment: with embodiment 1

[0028] Specific operation:

[0029] In the batching tank, add 2-keto-L-gulonic acid and methanol according to the mass volume ratio of 2-keto-L-gulonic acid and methanol at a ratio of 1:6, and then add 2-keto-L-gulonic acid according to the The mass volume ratio of acid to concentrated sulfuric acid is 1:0.01. Slowly add concentrated sulfuric acid, start stirring, and the uniformly mixed feed liquid T1 is continuously added to the feed heat exchanger for heating, so that the feed liquid temperature rises to 76°C, and then enters the tube React in reactor B, keep the temperature in the reactor at 76°C, the pressure at 0.3MPa, control the residence time of the feed liquid in tubular reactor B to 40min, and flow out of tubular reactor B, that is, the ester after esterification As a heat source, the chemical liquid T2 is passed into the primary heat exchanger formed by the countercurrent flow of the first heat exchanger A1 in front...

Embodiment 3

[0031] Production equipment: with embodiment 1

[0032] Specific operation:

[0033] In the batching tank, add 2-keto-L-gulonic acid and methanol according to the mass volume ratio of 2-keto-L-gulonic acid and methanol at a ratio of 1:5, and then add 2-keto-L-gulonic acid according to the The mass volume ratio of acid to concentrated sulfuric acid is 1:0.004. Slowly add concentrated sulfuric acid, start stirring, and the uniformly mixed feed liquid T1 is continuously added to the feed heat exchanger for heating, so that the feed liquid is heated to 90°C, and then enters the tube React in reactor B, keep the temperature in the reactor at 90°C, the pressure at 0.45MPa, control the residence time of the feed liquid in tube reactor B to 20min, and flow out of tube reactor B, that is, the ester after esterification As a heat source, the chemical liquid T2 is passed into the primary heat exchanger formed by the countercurrent flow of the first heat exchanger A1 in front of the feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com