Inorganic anti-doodling environmentally-friendly coating material and preparation method thereof

An environmentally friendly coating and anti-graffiti technology, applied in anti-corrosion coatings, anti-fouling/underwater coatings, alkali metal silicate coatings, etc., can solve the problems of high health risks and environmental pollution risks, high preparation costs, and high requirements for preparation operations , to achieve good hardness and wear resistance, enhanced adhesion, good hiding power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

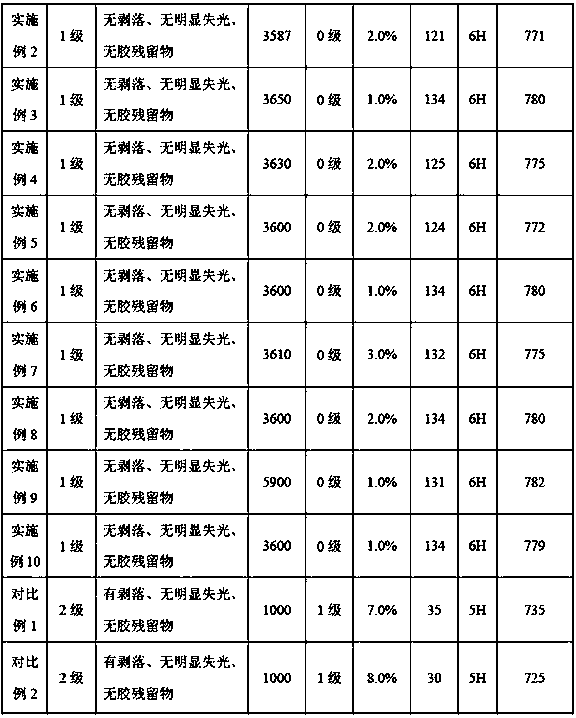

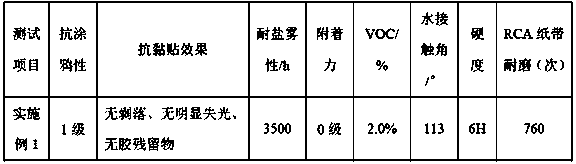

[0046] Embodiment 1: a kind of preparation method of inorganic anti-graffiti environment-friendly paint, comprises the steps:

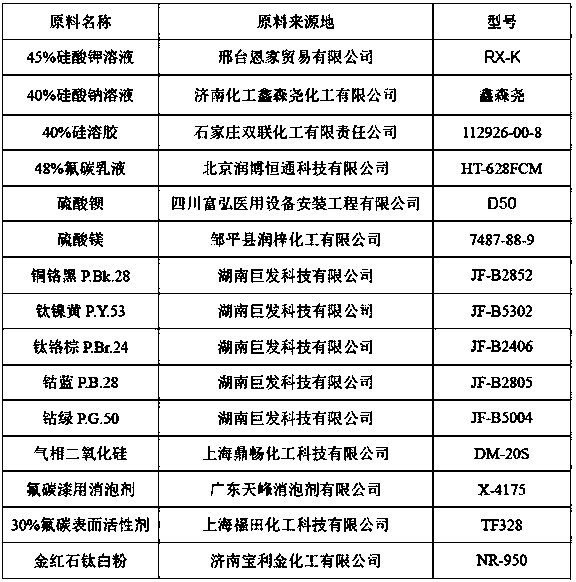

[0047] (1) Ingredients: Calculated per 1000 parts by weight of paint, weigh 100 parts of 45% potassium silicate solution, 100 parts of 40% sodium silicate solution, 100 parts of 40% silica sol solution, 50 parts of 48% fluorocarbon emulsion, rutile 20 parts of titanium dioxide, 15 parts of barium sulfate, 15 parts of magnesium sulfate, 1 part of fumed silica, 1 part of 30% fluorocarbon surfactant, 10 parts of copper chrome black, 0.5 part of defoamer for fluorocarbon paint, and the balance It is water; silica sol pH=8, D=30nm;

[0048] (2) Add water, defoamer for fluorocarbon paint, 30% fluorocarbon surfactant, fumed silica, rutile titanium dioxide, barium sulfate, and magnesium sulfate into the dispersion tank in sequence, 300r / Mix evenly at a rotating speed of 1300r / min, and then disperse at a rotating speed of 1300r / min for 40 minutes until the f...

Embodiment 2

[0052] A preparation method of an inorganic anti-graffiti environmental protection coating, comprising the steps of:

[0053] (1) Ingredients: Calculated according to 1000 parts by weight of paint, weigh 175 parts of 45% potassium silicate solution, 175 parts of 40% sodium silicate solution, 100 parts of 40% silica sol solution, 60 parts of 48% fluorocarbon emulsion, rutile titanium 30 parts of white powder, 15 parts of barium sulfate, 15 parts of magnesium sulfate, 6 parts of fumed silica, 3 parts of 30% fluorocarbon surfactant, 20 parts of copper chrome black, 0.6 part of defoamer for fluorocarbon paint, and the balance is Water; silica sol pH=8, D=30nm;

[0054] (2) Add water, defoamer for fluorocarbon paint, 30% fluorocarbon surfactant, fumed silica, rutile titanium dioxide, barium sulfate, and magnesium sulfate into the dispersion tank in sequence, 300r / Mix evenly at a rotating speed of 1300r / min, and then disperse at a rotating speed of 1300r / min for 40 minutes until t...

Embodiment 3

[0058] A preparation method of an inorganic anti-graffiti environmental protection coating, comprising the steps of:

[0059] (1) Ingredients: Calculated according to 1000 parts by weight of paint, weigh 185 parts of 45% potassium silicate solution, 185 parts of 40% sodium silicate solution, 125 parts of 40% silica sol solution, 70 parts of 48% fluorocarbon emulsion, rutile titanium 40 parts of white powder, 20 parts of barium sulfate, 20 parts of magnesium sulfate, 8 parts of fumed silica, 4 parts of 30% fluorocarbon surfactant, 2.5 parts of copper chrome black, 0.7 part of defoamer for fluorocarbon paint, and the balance is Water; silica sol pH=8, D=30nm;

[0060] (2) Add water, defoamer for fluorocarbon paint, 30% fluorocarbon surfactant, fumed silica, rutile titanium dioxide, barium sulfate, and magnesium sulfate into the dispersion tank in sequence, 300r / Mix evenly at a rotating speed of 1300r / min, and then disperse at a rotating speed of 1300r / min for 40 minutes until ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com