Hot-melt pressure-sensitive adhesive for viscosity modification of SBS asphalt waterproof coiled materials

A technology of bituminous waterproofing membrane and hot melt pressure sensitive adhesive, applied in the direction of adhesive, adhesive type, mineral oil hydrocarbon copolymer adhesive, etc. and other problems, to achieve the effect of good water impermeability, strong industrial application value and development prospects, and good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

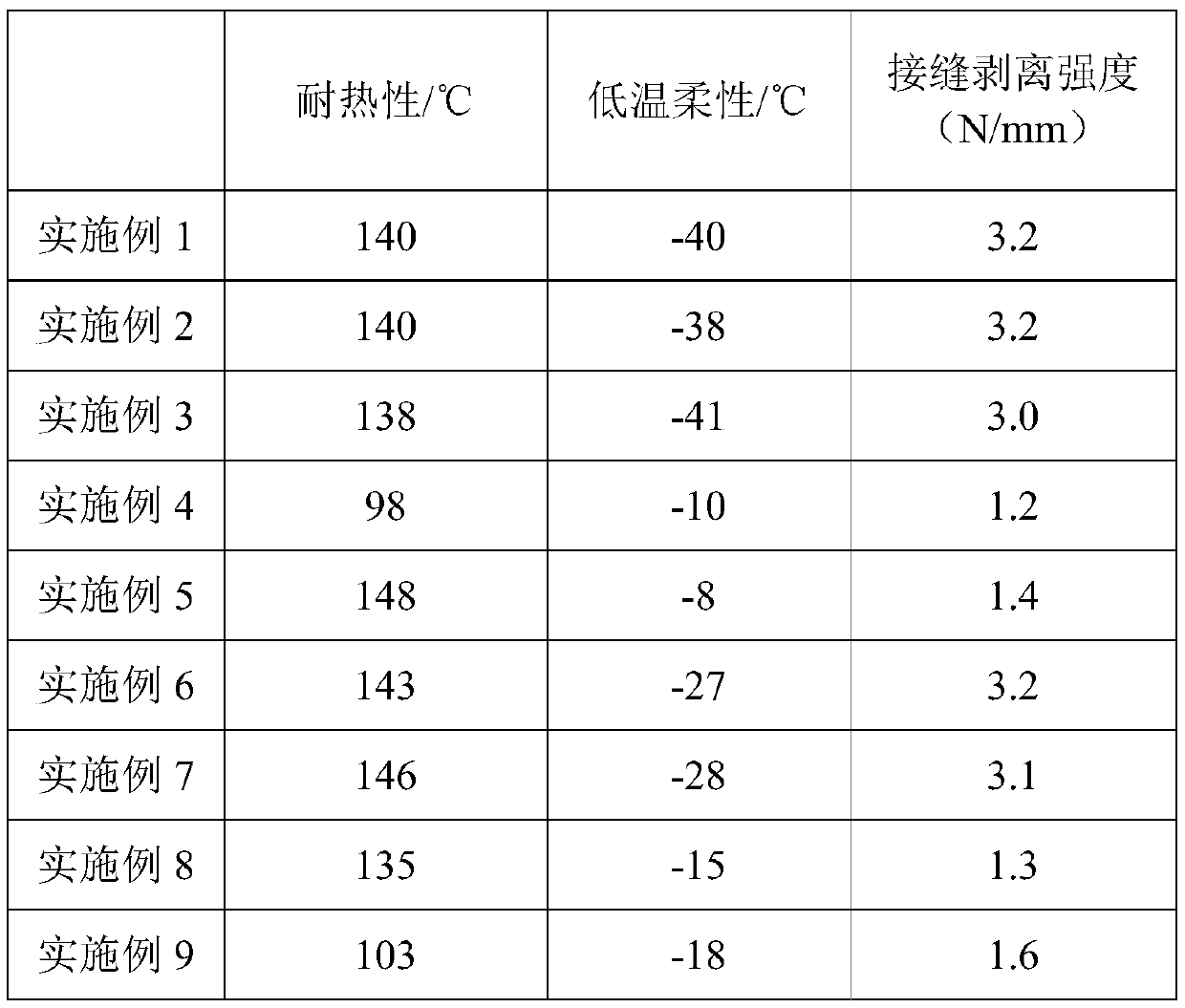

Examples

preparation example Construction

[0070] A second aspect of the present invention provides a method for preparing a hot-melt pressure-sensitive adhesive, comprising the following steps:

[0071] Step 1: adding petroleum resin and polyolefin resin into a stirring tank, stirring at a temperature of 150-160° C. for 40-50 minutes to obtain a mixture A;

[0072] Step 2: After heating the mixture A obtained in step 1 to 180-190° C., adding parts of SBS thermoplastic elastomer and SIS thermoplastic elastomer, stirring for 1-3 hours to obtain mixture B;

[0073] Step 3: After grinding the mixture B obtained in Step 2 through a colloid mill, at a temperature of 140-150° C., in parts by weight, stir and add antioxidant, plasticizer, and ultraviolet absorber, and stir for 30-50 minutes, that is A hot melt pressure sensitive adhesive is obtained.

[0074] In a preferred embodiment, the preparation method of the hot-melt pressure-sensitive adhesive comprises the following steps:

[0075] Step 1: adding petroleum resin an...

Embodiment 1

[0081] Embodiment 1 of the present invention provides a hot-melt pressure-sensitive adhesive, comprising, in parts by weight: 15 parts of SBS thermoplastic elastomer, 10 parts of SIS thermoplastic elastomer, 8 parts of polyolefin resin, 15 parts of petroleum resin, plasticizer 10 parts, 1.5 parts of antioxidant, 1.5 parts of ultraviolet absorber.

[0082] The SBS thermoplastic elastomer is an SBS thermoplastic elastomer with a Shore hardness of 85.

[0083] The SIS thermoplastic elastomer is a SIS thermoplastic elastomer with a Shore hardness of 40.

[0084] The polyolefin resin is polyethylene wax; the petroleum resin is C5 resin; the plasticizer is naphthenic oil; the weight ratio of the petroleum resin, polyolefin resin and plasticizer is 1:0.53:0.67 .

[0085] The antioxidant is antioxidant 1010; the ultraviolet absorber is UV-326.

[0086] The preparation method of the hot-melt pressure-sensitive adhesive is as follows:

[0087] Step 1: adding petroleum resin and poly...

Embodiment 2

[0091] Embodiment 2 of the present invention provides a hot-melt pressure-sensitive adhesive, comprising, in parts by weight: 14 parts of SBS thermoplastic elastomer, 9 parts of SIS thermoplastic elastomer, 7 parts of polyolefin resin, 14 parts of petroleum resin, plasticizer 9 parts, 1 part antioxidant, 1 part UV absorber.

[0092] The SBS thermoplastic elastomer is an SBS thermoplastic elastomer with a Shore hardness of 85.

[0093] The SIS thermoplastic elastomer is a SIS thermoplastic elastomer with a Shore hardness of 40.

[0094] The polyolefin resin is polyethylene wax; the petroleum resin is carbon five resin; and the plasticizer is naphthenic oil.

[0095] The antioxidant is antioxidant 1010; the ultraviolet absorber is UV-326.

[0096] The preparation method of the hot-melt pressure-sensitive adhesive is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com