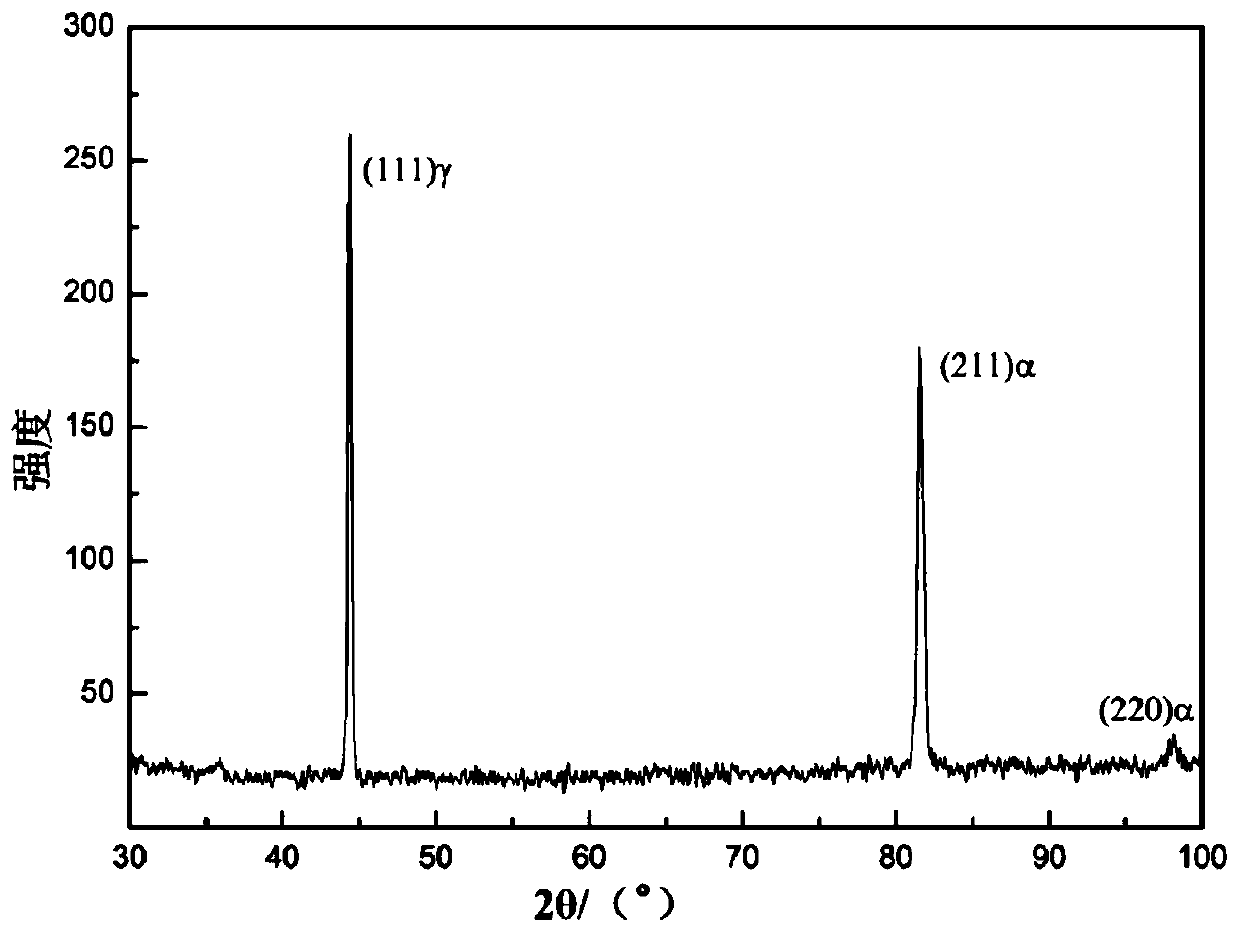

700 Mpa-level austenite ferrite dual-phase low-density cast steel and preparation method thereof

An austenitic ferrite, low-density technology, which is applied in casting molding equipment, molds, mold components, etc., can solve the problems of limited application scope of lightweight automobiles, unsuitable for large-scale promotion and application, and complex material properties. , to achieve good application prospects, high strength and plasticity, and the effects of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a preparation method of 700MPa-grade austenitic-ferritic dual-phase low-density cast steel, the method comprising the following steps:

[0028] a. Ingredients: use high-purity iron, electrolytic manganese, ferrosilicon, ferro-titanium, ferro-vanadium, ferro-niobium, aluminum particles, and carburizers as raw materials, and make ingredients according to the above ratio; the carburizers are artificial graphite, natural graphite or Any one of coke;

[0029] b. Molding: Use sodium silicate sand for molding, and blow carbon dioxide to harden the sand mold, then paint the inner wall of the sand mold, dry it, and wait for pouring;

[0030] c. Smelting: After adding high-purity iron into the medium-frequency induction furnace, the temperature is raised to above 1300°C. After the high-purity iron is completely melted, electrolytic manganese, ferrosilicon, ferro-titanium, ferro-vanadium, ferro-niobium, aluminum particles, and recarburizer are add...

Embodiment 1

[0041] Ingredients: Calculate the mass of each material according to the mass percentages of target components C: 0.82%, Mn: 18%, Si: 0.2%, V: 0.08%, Ti: 0.11%, Al: 12%, and Nb: 0.12%. Large pieces of charge such as high-purity iron are weighed with a 100kg electronic scale, and charges with a small amount of carburant, ferroniobium, and ferrovanadium are weighed with a 200g electronic scale. Dry processing, each furnace batching 100kg.

[0042] Table 1 Master alloy material list (unit wt%)

[0043] mn Si Ti V Nb C S P Al High purity iron 0.04 0.012 0 0 0 0.003 0.005 0.004 0 Electrolytic manganese 99.58 0.015 0 0 0 0 0.100 0.010 0 Ferrosilicon 0 72.10 0 0 0 0.100 0.016 0.034 1.50 Titanium Sponge 0 0.06 99.3 0 0 0 0.010 0.050 0 Ferrovanadium 0.29 1.76 0 49.35 0 0.330 0.001 0.045 0.50 Ferroniobium 0 2.81 0 0 65.50 0.100 0.060 0.190 0.42 Aluminum particles 0 0 0 0 ...

Embodiment 2

[0052] Calculate the mass of each material (high-purity iron, electrolytic manganese , ferrosilicon, titanium sponge, ferrovanadium, ferroniobium, aluminum particles, recarburizer). The batching, molding, smelting and pouring methods are as shown in Example 1, the difference is: in the heat treatment step, the casting is solid solutioned at 1000°C for 2 hours, cooled to room temperature with water, then aged at 500°C for 6.5 hours, and air cooled to room temperature. The austenitic-ferritic dual-phase low-density cast steel with the composition shown in Example 2 in Table 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com