Wear-resistance artificial turf capable of being cooled and preparation method thereof

An artificial turf and ball mill technology, which is applied in the manufacture of rayon, single-component polyolefin rayon, single-component polyamide rayon, etc. problems such as poor ability to achieve the effect of improving hydrophilic performance and water holding performance, improving sports safety, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

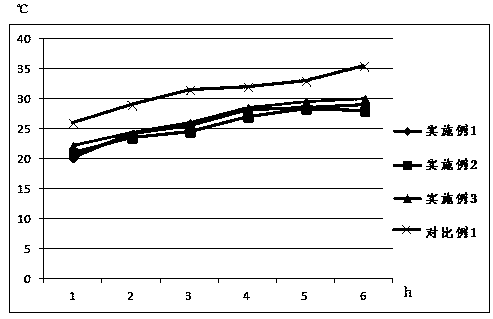

Image

Examples

Embodiment 1

[0034](1) Add nano titanium dioxide, fumed white carbon black, nano lithopone, and nano talc powder into a ball mill for grinding and mixing to obtain an anti-infrared heat-insulating powder material; the material-ball ratio for grinding and mixing is 5, and the filling rate of the ball mill is 20%, the speed is 250r / min, and the grinding time is 3h;

[0035] The ratio of each raw material is, by mass percentage, nano titanium dioxide 7%, fumed white carbon black 8%, nano lithopone 10%, nano talcum powder 75%;

[0036] (2) Maintain a stirring speed of 60r / min, first add the anti-infrared heat insulation powder material, silane coupling agent, and glass powder obtained in step (1) at a mass ratio of 10:0.1:100, and increase the stirring speed to 200r / min, after stirring for 60min, composite powder was obtained; the silane coupling agent was kh550;

[0037] (3) First heat the composite powder obtained in step (2) until the glass powder is melted, and spin the filaments in an i...

Embodiment 2

[0041] (1) Add nano titanium dioxide, fumed white carbon black, nano lithopone, and nano talc powder into a ball mill for grinding and mixing to obtain an anti-infrared heat-insulating powder material; the material-ball ratio for grinding and mixing is 7, and the filling rate of the ball mill is 20%, the speed is 200r / min, and the grinding time is 5h;

[0042] The ratio of each raw material is, by mass percentage, 4% of nano titanium dioxide, 6% of fumed white carbon black, 10% of nano lithopone, and 80% of nano talcum powder;

[0043] (2) Maintain a stirring speed of 40r / min, first add the anti-infrared heat insulation powder material, silane coupling agent, and glass powder obtained in step (1) at a mass ratio of 15:0.5:100, and increase the stirring speed to 200r / min, after stirring for 60min, composite powder was obtained; the silane coupling agent was kh550;

[0044] (3) First heat the composite powder obtained in step (2) until the glass powder is melted, and spin the ...

Embodiment 3

[0047] (1) Add nano titanium dioxide, fumed white carbon black, nano lithopone, and nano talc powder into a ball mill for grinding and mixing to obtain an anti-infrared heat-insulating powder material; the material-ball ratio for grinding and mixing is 5, and the filling rate of the ball mill is 20%, the speed is 220r / min, and the grinding time is 4h;

[0048] The ratio of each raw material is, by mass percentage, nano titanium dioxide 4%, fumed white carbon black 8%, nano lithopone 10%, nano talcum powder 78%;

[0049] (2) Maintain a stirring speed of 60r / min, first add the anti-infrared heat insulation powder material obtained in step (1), silane coupling agent, and glass powder at a mass ratio of 12:0.3:100, and increase the stirring speed to 250r / min, after stirring for 90min, composite powder was obtained; the silane coupling agent was kh550;

[0050] (3) First heat the composite powder obtained in step (2) until the glass powder is melted, and spin the filaments in an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com