Treatment system coupling iron-promoted magnetic loading anaerobic/anoxic activated sludge process and biofilm process

A technology of activated sludge method and biofilm method, which is applied in the field of iron-promoted magnetic loading anaerobic/anoxic activated sludge method and biofilm method coupling treatment system, which can solve the problem of insufficient carbon source, frequent sludge bulking, and land occupation Large and other problems, to achieve the effect of improving the specific gravity and settling performance, increasing the concentration of activated sludge, and no risk of sludge bulking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

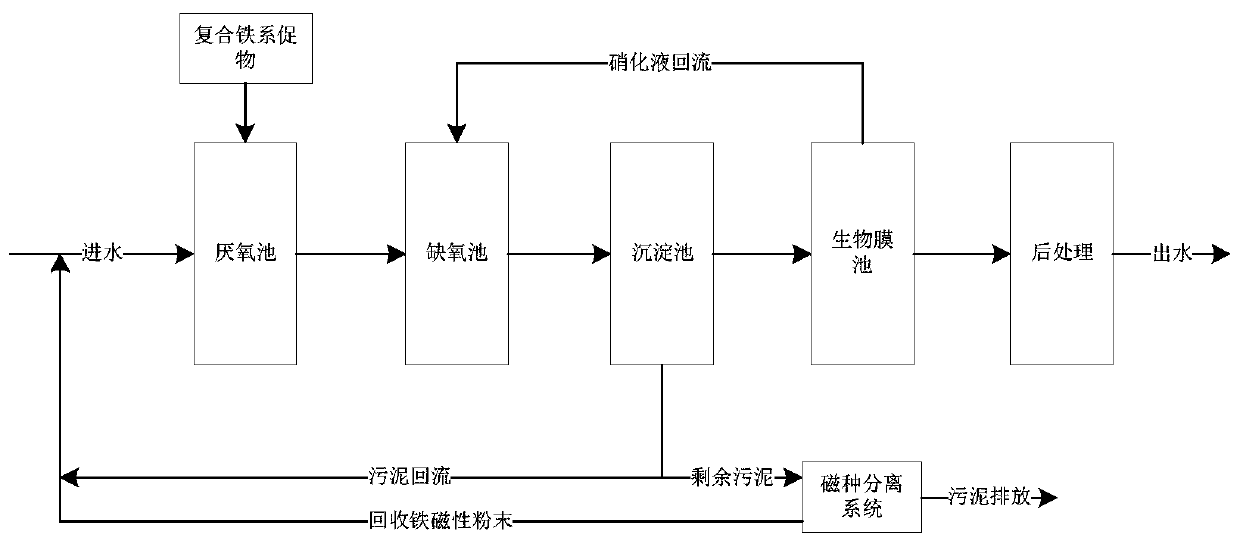

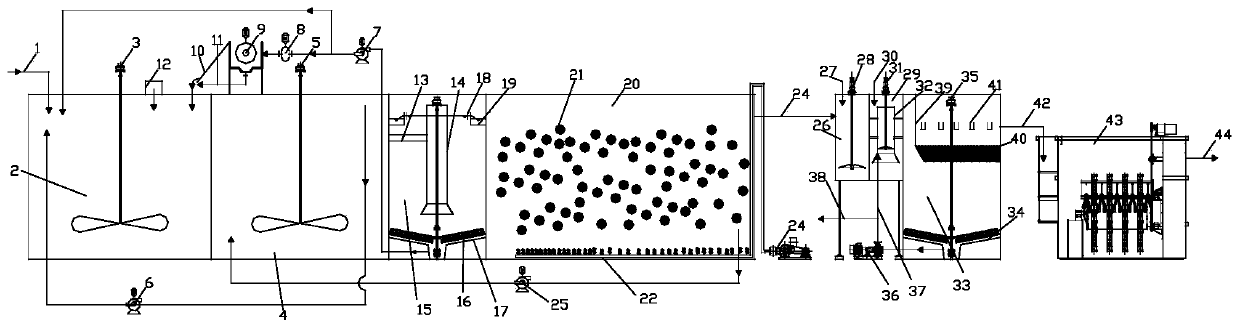

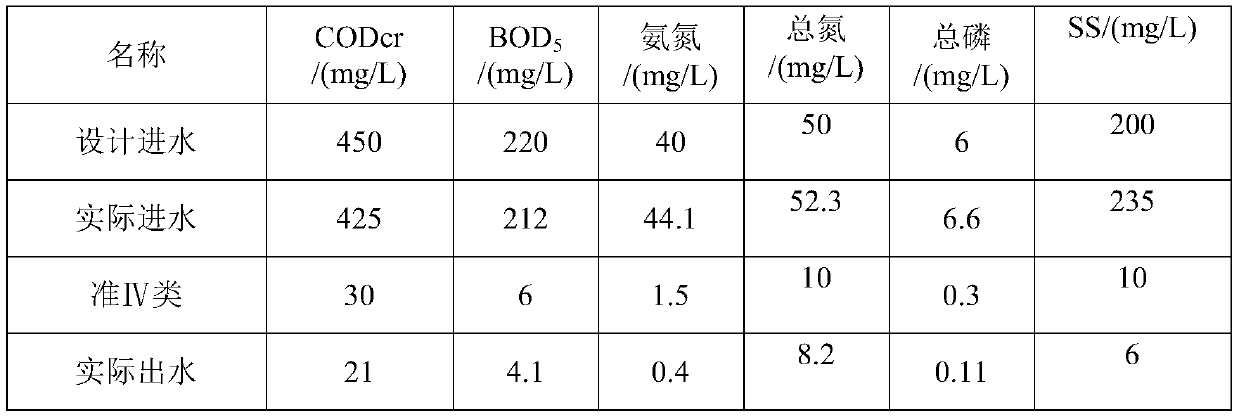

[0060] The invention discloses an iron-promoted magnetic loading anaerobic / anoxic activated sludge method and a biofilm method coupling treatment system, such as figure 1 As shown, it includes anaerobic tank, anoxic tank, sedimentation tank, biofilm tank and post-treatment system connected in sequence. system is connected.

[0061] In particular, the above-mentioned anaerobic tank is provided with a water inlet, a sludge return inlet, a composite iron-based accelerator input inlet, an anaerobic mixed liquid outlet, and an inlet for recovering ferromagnetic powder; the sewage enters the anaerobic tank through the water inlet, and the composite The inlet for adding iron-based accelerators is connected to the outlet for adding composite iron-based accelerators of the compound iron-based accelerator dosing system; an anaerobic agitator is provided in the above-mentioned anaerobic pool.

[0062] In particular, the above-mentioned anoxic pool is provided with an anaerobic mixed liq...

Embodiment 2

[0072] The difference from Example 1 is:

[0073] The above-mentioned sedimentation tank is a vertical flow sedimentation tank.

[0074]The above-mentioned biofilm tank is also equipped with a bottom aeration system, and an agitator can also be added according to actual needs. The bottom aeration system adopts perforated "aeration + microporous" combined aeration.

[0075] The biofilm pool mentioned above is a biological contact oxidation pool.

[0076] The above-mentioned post-treatment system is used for subsequent treatment after sewage treatment, including a mud-water separation and sedimentation device and a filtration device.

[0077] The above-mentioned composite iron-based promoter selects ferric oxide powder (Fe 3 o 4 ); and the particle size of ferric oxide powder added is 100 μm.

Embodiment 3

[0079] The difference from Example 1 is:

[0080] The above-mentioned sedimentation tank is selected as inclined tube (plate) sedimentation tank.

[0081] The above-mentioned biofilm pool is also equipped with a membrane aeration system, and an agitator can also be added according to actual needs. The membrane aeration system adopts microporous aeration.

[0082] The biofilm pool mentioned above is a biological aerated filter (BAF) and a membrane aerobic biofilm reactor (MABR).

[0083] The above-mentioned post-treatment system is used for subsequent treatment after sewage treatment, including a filter device, a deep denitrification and dephosphorization device and a disinfection device.

[0084] The above-mentioned composite iron-based promoter selects ferric oxide powder (Fe 3 o 4 ), FeCl 3 , Polyferric sulfate (PFS); the particle size of ferric oxide powder added is 200μm; 3 , PFS dosing and proportioning can be adjusted to meet the requirements of stable and up-to-sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com