Fabrication method of surface relief grating structure

A grating structure and manufacturing method technology, applied in the direction of diffraction grating, optics, optical elements, etc., can solve the problems that laser direct writing cannot accurately control the contour depth, contour depth error, low work efficiency, etc., and achieve precise control of substrate etching depth , widely used, and the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

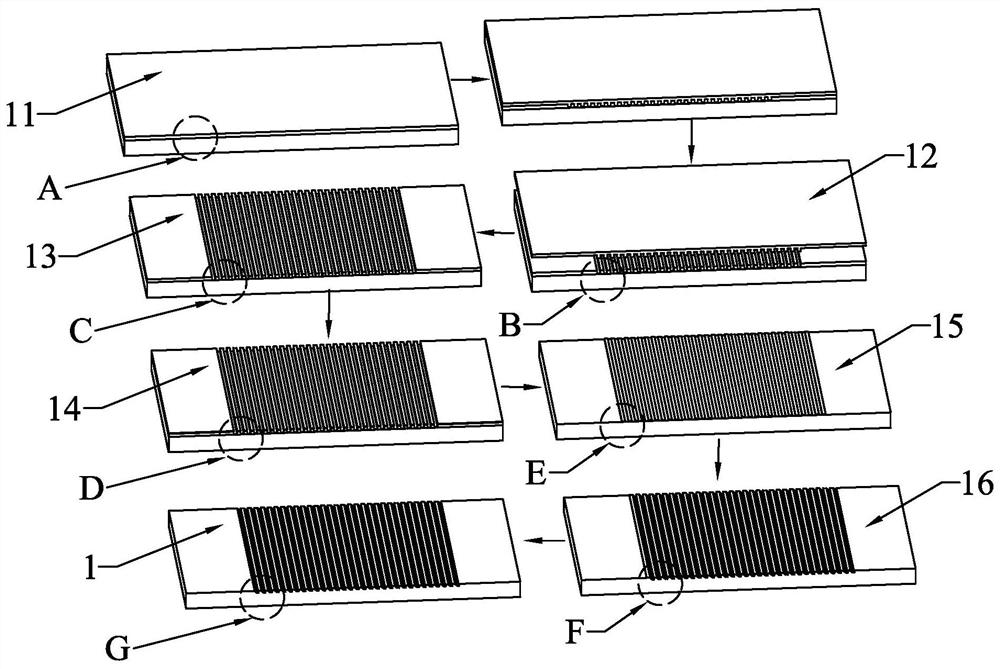

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

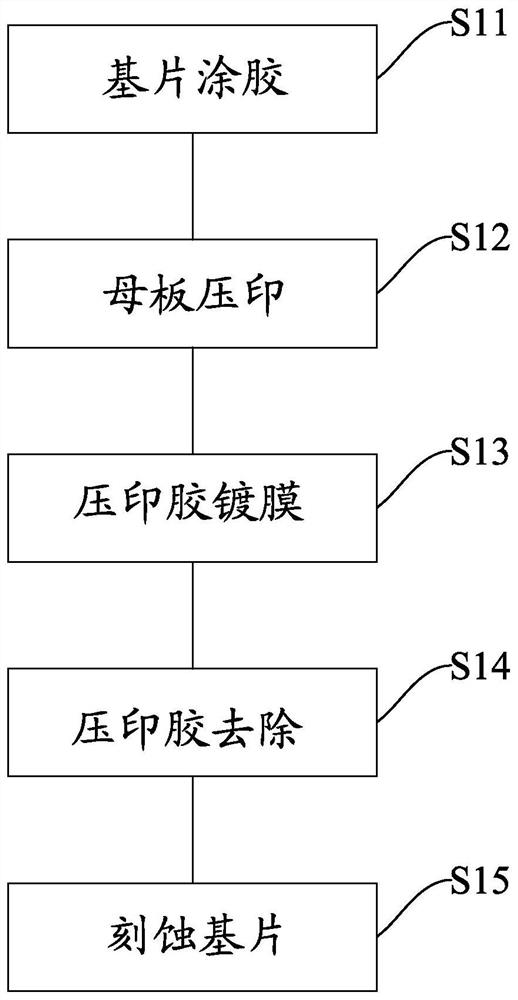

[0040] see Figure 1-2 , the invention discloses a method for manufacturing a surface relief grating structure, comprising the following steps:

[0041] Before coating the embossing adhesive layer, the substrate needs to be placed in cleaning equipment, soaked in absolute ethanol and acetone to remove residual organic matter, and then rinsed and dried with a large amount of deionized water; the material of the substrate is generally Glass material.

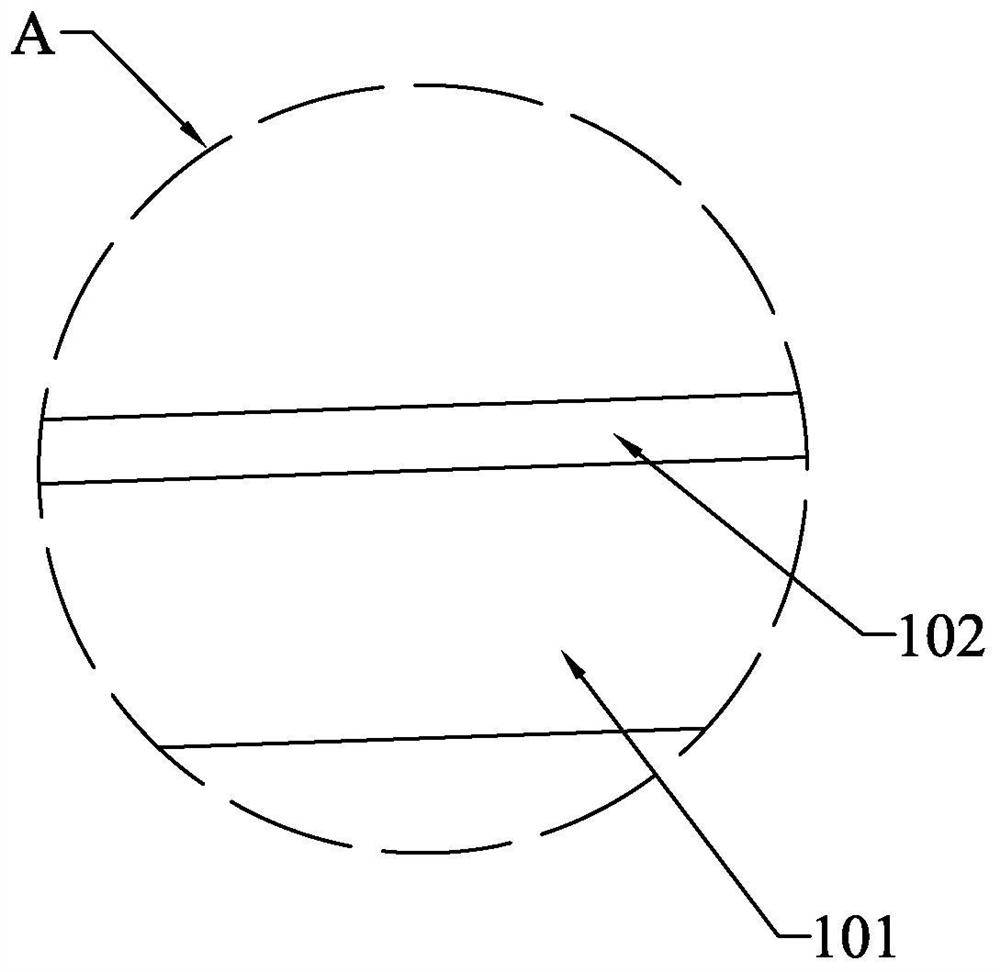

[0042] S1, substrate coating: please refer to further image 3 , providing the substrate 101 for making the grating structure, coating the embossing glue layer 102 on the surface of the substrate 101 to obtain the substrate 11; coating a layer of embossing glue on the substrate 101, when the glue concentration and the spin coating rate are different When the time changes, the thickness of a single spin c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com