Monascus bean dreg vinegar and preparation method thereof

A technology of bean dregs and red yeast rice, which is applied in the field of red yeast bean dregs vinegar and its preparation, can solve the problems of low dietary fiber content, irritation, and monotonous flavor, and achieve the effects of reducing the color mixing process, promoting gastrointestinal motility, and increasing flavor Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

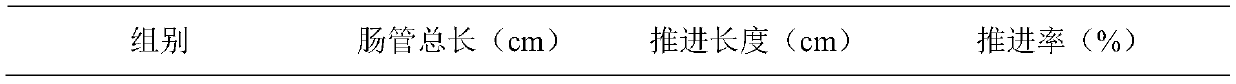

Examples

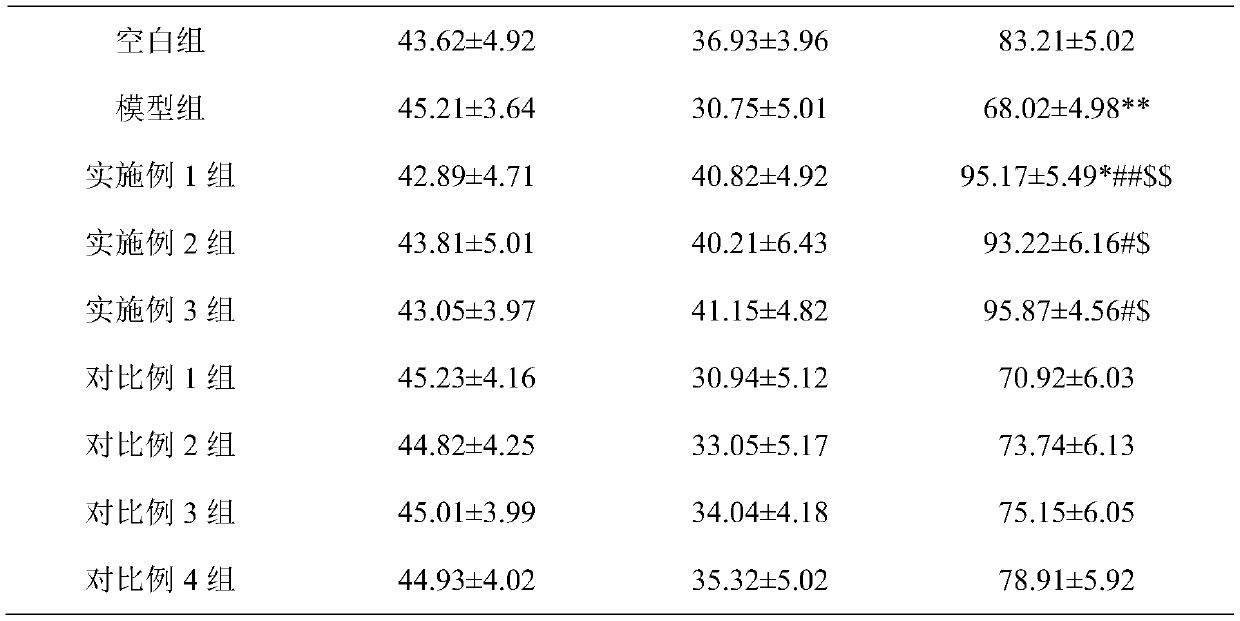

Embodiment 1

[0038] Embodiment 1: the preparation of red yeast bean dregs vinegar

[0039] A kind of red koji bean dregs vinegar is prepared by the following method:

[0040] (1) Raw material preparation: Weigh 120 parts of soybean dregs, 60 parts of millet, 20 parts of sorghum, 15 parts of bean dregs and red yeast rice, and 2 parts of honey as required. Water is mixed according to the mass volume ratio of 1:7, and sterilized at 100°C for 25 minutes;

[0041] (2) Cooking and liquefaction: Cool the sterilized raw material slurry to 65°C, add 0.01% high temperature resistant amylase, liquefy at 90°C for 25 minutes, cool to 55°C, add 0.2% (v / v) cellulase , enzymolysis reaction for 2 hours, to obtain enzymatic pulp; among them, the high temperature resistant amylase, the enzyme activity is 3000U / L, and the cellulase, the enzyme activity is 2500U / L.

[0042](3) Alcoholic fermentation: the enzymolysis slurry is lowered to 28°C, and the bean dregs and red yeast rice are mixed into the enzymolys...

Embodiment 2

[0055] Embodiment 2: the preparation of red yeast bean dregs vinegar

[0056] A kind of red koji bean dregs vinegar is prepared by the following method:

[0057] (1) Raw material preparation: Weigh 90 parts of soybean dregs, 50 parts of black bean dregs, 80 parts of millet, 25 parts of sorghum, 10 parts of red yeast rice, and 3 parts of honey. Mesh sieve, mix the raw materials and water according to the mass volume ratio of 1:8, and sterilize at 95°C for 30 minutes;

[0058] (2) Cooking liquefaction: Cool the sterilized raw material slurry to 65°C, add 0.01% high temperature resistant amylase, liquefy at 80°C for 30 minutes, cool to 60°C, add 0.3% (v / v) cellulase , enzymolysis reaction 1.5h, the preparation of enzymatic pulp; Among them, high temperature resistant amylase, enzyme activity is 3000U / L, cellulase, enzyme activity is 2500U / L.

[0059] (3) Alcoholic fermentation: the enzymolysis slurry is lowered to 30°C, and the bean dregs and red yeast rice are mixed into the e...

Embodiment 3

[0073] Embodiment 3: the preparation of red yeast bean dregs vinegar

[0074] A kind of red koji bean dregs vinegar is prepared by the following method:

[0075] (1) Raw material preparation: Weigh 110 parts of soybean dregs, 20 parts of red bean dregs, 20 parts of black bean dregs, 50 parts of millet, 30 parts of sorghum, 15 parts of red yeast rice with bean dregs, and 4 parts of honey, and crush the bean dregs, millet and sorghum Finally, pass through a 40-mesh sieve, add water according to the mass volume ratio of raw materials and water at 1:10, and sterilize at 90°C for 30 minutes;

[0076] (2) Cooking and liquefaction: cool the sterilized raw material slurry to 68°C, add 0.015% high temperature resistant amylase, liquefy at 85°C for 25 minutes, cool to 55°C, add 0.25% (v / v) cellulase , enzymatic hydrolysis reaction for 1h, to obtain enzymatic pulp; among them, the high temperature resistant amylase, the enzyme activity is 3000U / L, and the cellulase, the enzyme activity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com