Graphene composite material cable and production method thereof

A composite material and production method technology, applied in the direction of insulated cables, chemical instruments and methods, cables, etc., can solve the problems of high cost and complex process, and achieve the effects of high strength, high flexibility, and avoiding complex weaving processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

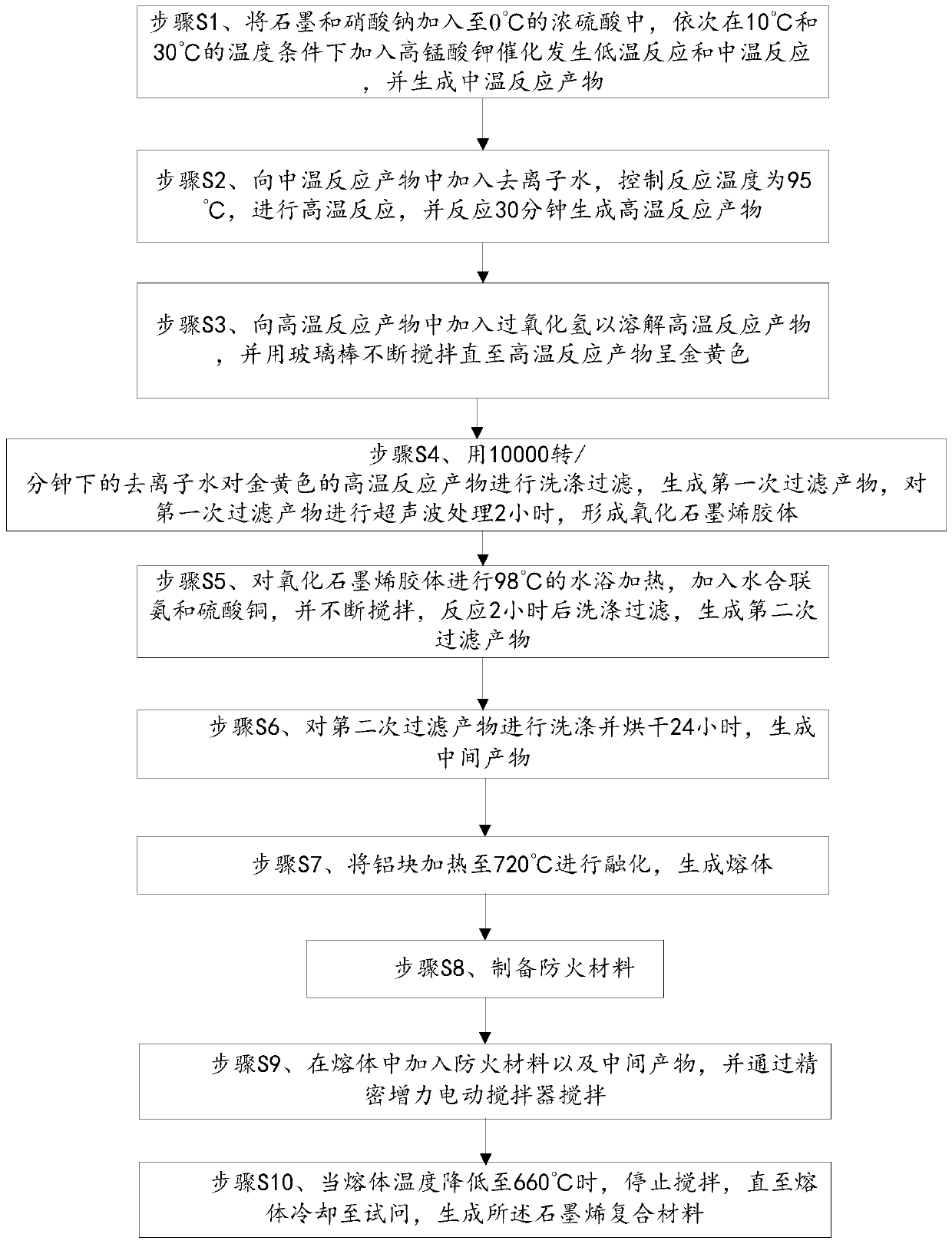

Method used

Image

Examples

Embodiment 1

[0029] In one of the embodiments of the present invention, the raw materials of the graphene composite material, by weight percentage, include: graphite 6%, sodium nitrate 3%, potassium permanganate 18%, concentrated sulfuric acid 12%, deionized water 34% , 10% hydrogen peroxide, 5% hydrazine tetrahydrate, 5% copper sulfate, 5% aluminum block, 2% fireproof material. In the present invention, the composite material with high flexibility and good strength can be obtained under the reinforcement of graphene through the aluminum block, which meets the use requirements of cables.

[0030] The above-mentioned raw materials are all purchased on the market, wherein the chemical formula of sodium nitrate is NaNO 3 , the chemical formula of potassium permanganate is KMnO 4 , the chemical formula of concentrated sulfuric acid is H 2 SO 4 , the chemical formula of hydrogen peroxide is H 2 o 2 , the chemical formula of hydrazine hydrate is N 2 h 4 ·H 2 O, the chemical formula of co...

Embodiment 2

[0038] In one of the embodiments of the present invention, the raw materials of the graphene composite material, by weight percentage, include: graphite 6%, sodium nitrate 3%, potassium permanganate 18%, concentrated sulfuric acid 12%, deionized water 34% , 10% hydrogen peroxide, 5% hydrazine tetrahydrate, 5% copper sulfate, 5% aluminum block, 2% fireproof material. In the present invention, the composite material with high flexibility and good strength can be obtained under the reinforcement of graphene through the aluminum block, which meets the requirements for use of cables. The raw materials of fireproof materials are calculated by weight percentage, including: aluminum silicate 65%, aluminum tripolyphosphate 4%, polyaluminosiloxane 12%, magnesium hydroxide 7%, water glass 4%, glass fiber 3%, emery 2 %, talcum powder 2%, melamine 1%.

Embodiment 3

[0040] In one of the embodiments of the present invention, the raw materials of the graphene composite material, by weight percentage, include: graphite 5%, sodium nitrate 2%, potassium permanganate 15%, concentrated sulfuric acid 12%, deionized water 35% , 10% hydrogen peroxide, 6% hydrazine hydrate, 6% copper sulfate, 6% aluminum block, 3% fireproof material. In the present invention, the composite material with high flexibility and good strength can be obtained under the reinforcement of graphene through the aluminum block, which meets the requirements for use of cables. The raw materials of fireproof materials are calculated by weight percentage, including: aluminum silicate 65%, aluminum tripolyphosphate 4%, polyaluminosiloxane 12%, magnesium hydroxide 7%, water glass 4%, glass fiber 3%, emery 2 %, talcum powder 2%, melamine 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com