Full-water-electrolysis catalyst, and preparation method and application thereof

A catalyst and water-splitting technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrolytic processes, etc., can solve the problems of synthesizing single-metal catalysts, unsolved oxidation decomposition, and difficulty in controlling the loading of active components. High stability, improved stability and activity, high activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

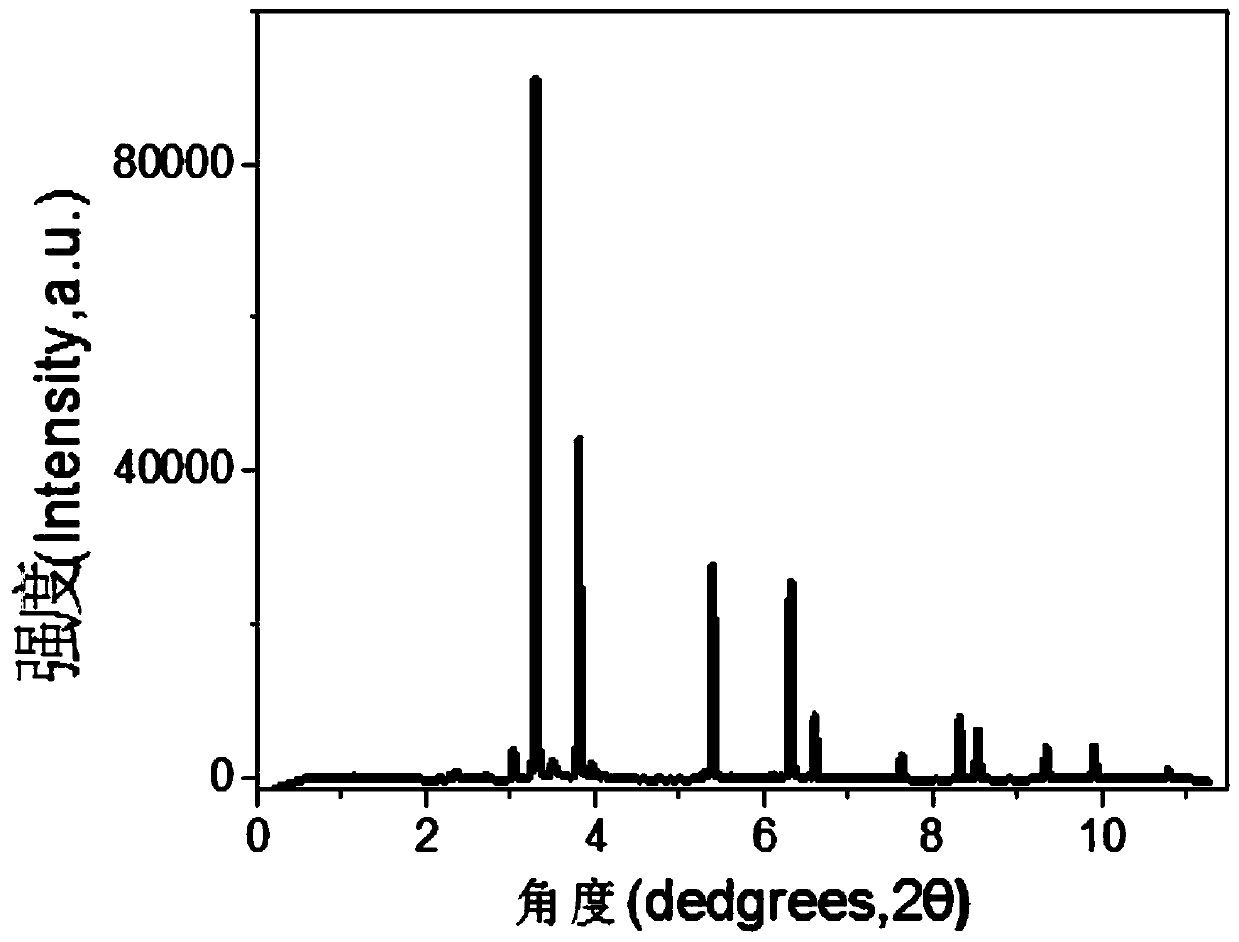

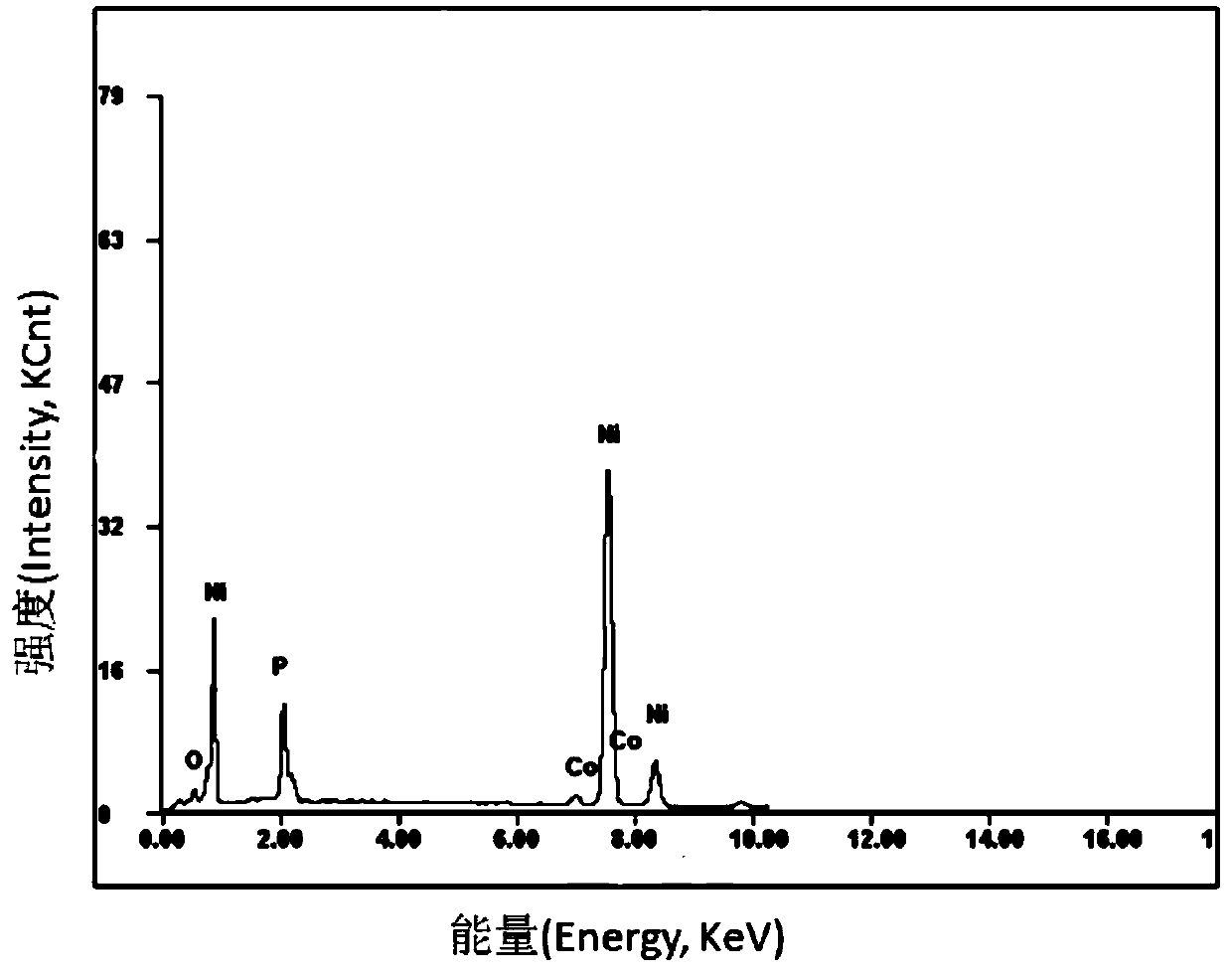

[0070] This embodiment provides a catalyst for total water splitting, wherein the catalyst is prepared by the following method:

[0071] 1) Mix 1.4cm×1cm three-dimensional nickel foam with hydrogen peroxide and ultrasonically infiltrate hydrogen peroxide into the nickel foam skeleton to obtain mixture A. Mixture A is oxidized at 120°C for 2 hours, then washed and dried to obtain oxidized three-dimensional nickel foam ; After mixing the oxidized three-dimensional nickel foam with a mass ratio of 1:10 and the first part of sodium hypophosphite, the reaction is carried out under an inert atmosphere at 2°C / min from room temperature to 325°C and kept at a constant temperature for 2h to obtain a three-dimensional Nickel Foam Carrier Derived Ni 2 P film is a single-component phosphide precursor;

[0072] 2) Disperse the obtained single-component phosphide precursor (about 2.04 g) with 1 mmol of cobalt nitrate hexahydrate, 0.5 mmol of nickel nitrate hexahydrate, 1 mmol of urea and 2 ...

Embodiment 2

[0074] This embodiment provides a catalyst for total water splitting, wherein the catalyst is prepared by the following method:

[0075] 1) Mix 1.4cm×1cm three-dimensional nickel foam with hydrogen peroxide and ultrasonically make the hydrogen peroxide penetrate into the nickel foam skeleton to obtain mixture A. Mixture A is oxidized at 80°C for 1 hour, then washed and dried to obtain the oxidized three-dimensional nickel foam ; After mixing the oxidized three-dimensional nickel foam with a mass ratio of 1:3 and the first part of sodium hypophosphite, the reaction is carried out under an inert atmosphere at 2°C / min from room temperature to 300°C and kept at a constant temperature for 1h to obtain a three-dimensional Nickel Foam Carrier Derived Ni 2 P film is a single-component phosphide precursor;

[0076] 2) Disperse the obtained single-component phosphide precursor with 1.125 mmol of cobalt nitrate hexahydrate, 0.375 mmol of nickel nitrate hexahydrate, and 3 mmol of sodium ...

Embodiment 3

[0078] This embodiment provides a catalyst for total water splitting, wherein the catalyst is prepared by the following method:

[0079] 1) Mix 1.4cm×1cm three-dimensional nickel foam with hydrogen peroxide and ultrasonically make hydrogen peroxide penetrate into the nickel foam skeleton to obtain mixture A. Mixture A is oxidized at 160°C for 4 hours, then washed and dried to obtain the three-dimensional nickel foam after oxidation treatment ; After mixing the oxidized three-dimensional nickel foam with a mass ratio of 1:20 and the first part of sodium hypophosphite, the reaction is carried out under an inert atmosphere at 10°C / min from room temperature to 360°C and kept at a constant temperature for 4h to obtain a three-dimensional Nickel Foam Carrier Derived Ni 2 P film is a single-component phosphide precursor;

[0080] 2) Disperse the obtained one-component phosphide precursor with 0.75 mmol of cobalt nitrate hexahydrate, 0.75 mmol of nickel nitrate hexahydrate, 1 mmol of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com