Preparation method of wave-absorbing foam for absorbing low-frequency electromagnetic waves

An electromagnetic wave and foam technology, which is applied in the field of preparation of wave-absorbing foam, can solve the problem of low absorption performance of wave-absorbing foam, achieve good absorption effect, reduce density, and reduce weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

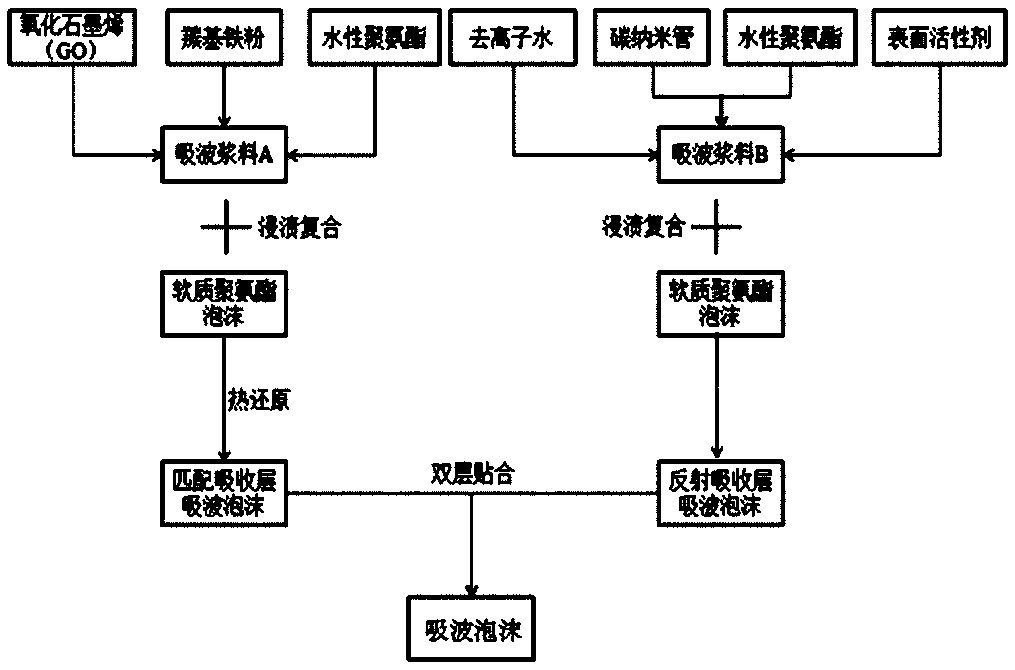

[0038] Such as figure 1 Shown, a kind of preparation method for the wave-absorbing foam of low-frequency electromagnetic wave absorption, comprises the following steps:

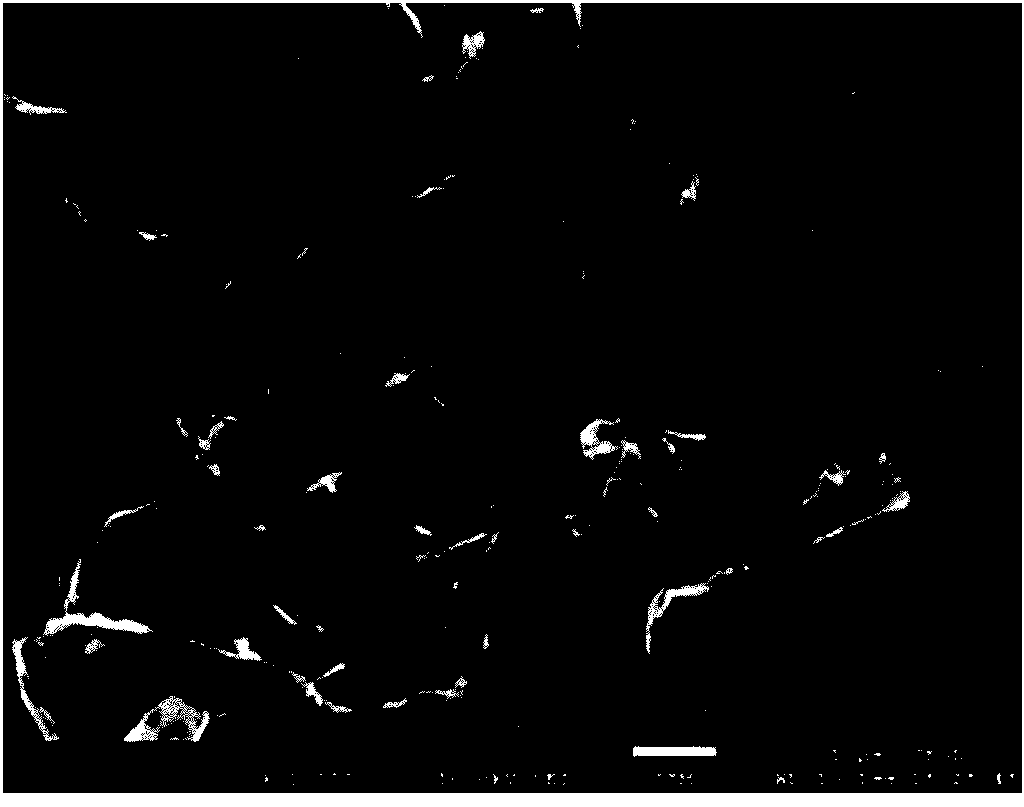

[0039] S1. Mix graphene oxide powder, carbonyl iron powder, and water-based polyurethane emulsion evenly to obtain microwave-absorbing slurry A. The SEM image of microwave-absorbing slurry A is as follows figure 2 shown;

[0040] S2. After fully impregnating the first flexible polyurethane foam in the wave-absorbing slurry A in S1, perform thermal reduction in a Teflon reactor, the thermal reduction temperature is 85-95°C, and the thermal reduction time is 12-15 hours;

[0041] S3. After the reaction is completed, the foam after thermal reduction in S2 is fully rinsed with deionized water, and then dried to obtain a wave-absorbing foam that matches the absorbing layer;

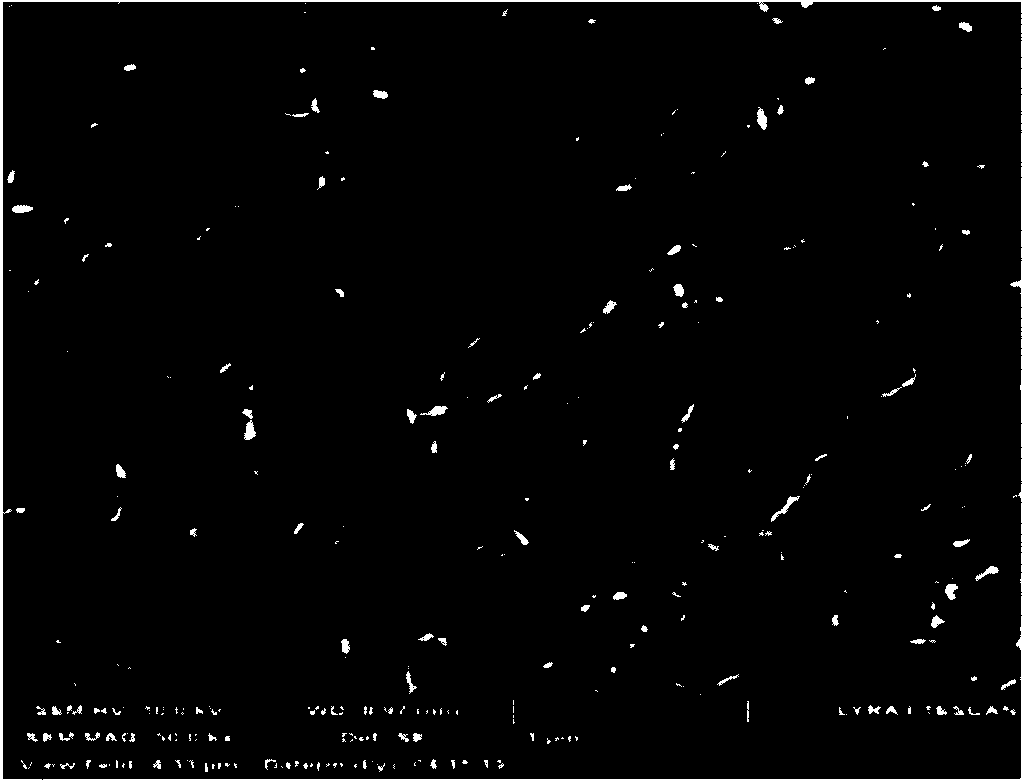

[0042] S4. Mix multi-walled carbon nanotube powder, deionized water, surfactant, and water-based polyurethane emulsion evenly to obtain m...

Embodiment 1

[0050] 1) Mix 8.2 g of graphene oxide (GO) powder, 16.4 g of carbonyl iron powder, and 250 mL of water-based polyurethane emulsion with a solid content of 30% to obtain microwave-absorbing slurry A;

[0051] 2) After fully impregnating the flexible polyurethane foam with a size of 180 mm×180 mm×10 mm in the microwave-absorbing slurry A, transfer it to a Teflon reactor, and heat reduce it at 95 °C for 12 h;

[0052] 3) After the reaction is completed, take the foam out of the Teflon reactor and fully rinse it with deionized water, and then dry it to obtain a wave-absorbing foam that matches the absorbing layer;

[0053] 4) Mix 12.5 g of multi-walled carbon nanotubes, 400 mL of deionized water, 3.8 g of sodium dodecylsulfonate, and 100 mL of water-based polyurethane emulsion with a solid content of 30% to obtain microwave-absorbing slurry B;

[0054] 5) After fully impregnating the flexible polyurethane foam with a size of 180 mm×180 mm×10 mm in the absorbing slurry B, dry it to...

Embodiment 2

[0057] 1) Mix 8.2 g of graphene oxide (GO) powder, 8.2 g of carbonyl iron powder, and 250 mL of water-based polyurethane emulsion with a solid content of 30% to obtain wave-absorbing slurry A;

[0058] 2) After fully impregnating the flexible polyurethane foam with a size of 300 mm×300 mm×10 mm in the microwave-absorbing slurry A, transfer it to a Teflon reactor, and heat reduce it at 85 °C for 15 h;

[0059] 3) After the reaction is completed, take the foam out of the Teflon reactor and fully rinse it with deionized water, and then dry it to obtain a wave-absorbing foam that matches the absorbing layer;

[0060] 4) Mix 12.5 g of multi-walled carbon nanotubes, 400 mL of deionized water, 4 g of carbon nanotube water-based dispersant (TNWDIS), and 50 mL of water-based polyurethane emulsion with a solid content of 30% to obtain microwave-absorbing slurry B;

[0061] 5) After fully impregnating the flexible polyurethane foam with a size of 300 mm×300 mm×10 mm in the absorbing slur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com