Collagen extraction and purification system

A collagen and raw material technology, applied in animal/human protein, biochemical instruments, organic chemistry, etc., can solve the problems of poor water solubility, low filtration level, high salt content, etc., and achieve the effect of good molecular weight uniformity and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

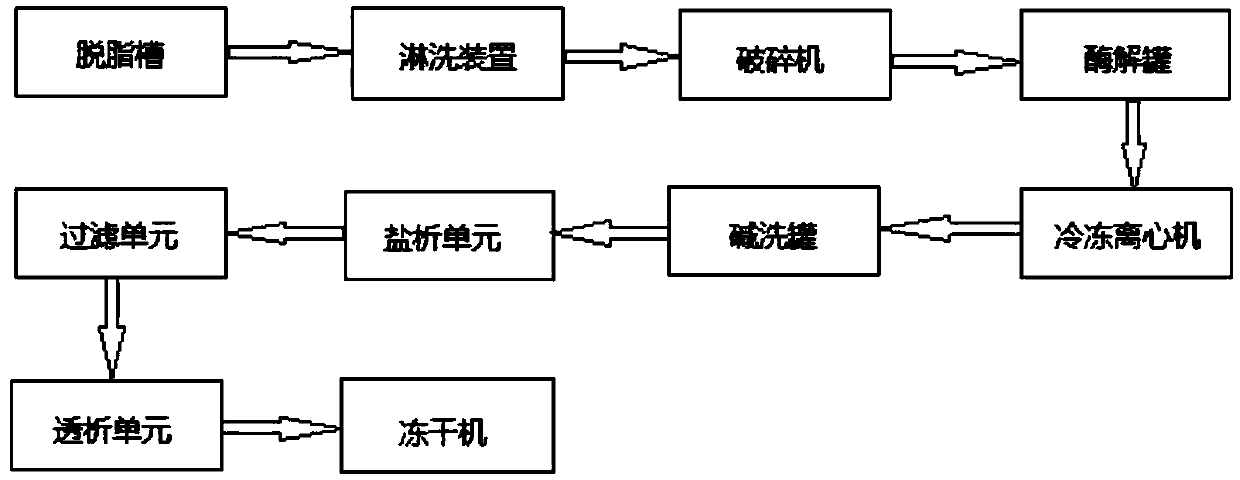

[0015] See figure 1 , the invention discloses a collagen extraction and purification system, comprising the following devices interconnected in sequence: a degreasing tank and a rinsing device for degreasing raw materials, a crusher for crushing degreased raw materials, and enzyme processing for crushed raw materials Enzyme hydrolysis tank for hydrolysis treatment, refrigerated centrifuge for refrigerated centrifugation treatment of enzymatic hydrolysis solution, alkali washing tank for alkaline washing treatment of precipitate obtained by refrigerated centrifugation, salting-out unit for salting-out treatment of alkaline washing solution, Filtration unit and dialysis unit for purification of crude collagen after salting out, freeze-drying unit for solidification of purified collagen.

[0016] Among them, the raw materials are fish skin, pig skin and other collagen-rich, low-cost and easy-to-obtain materials, which are added to the degreasing tank, added with chloroform / ethano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com