Supramolecular fracturing fluid system for imbibition oil recovery and application of supramolecular fracturing fluid system for imbibition oil recovery

A supramolecular and fracturing fluid technology, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high temperature resistance and shear resistance, difficult handling of fracturing flowback fluid, strong heterogeneity, etc. problems, to achieve the effect of increasing temperature resistance and shear resistance, improving sand-carrying capacity of joint making, and reducing interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

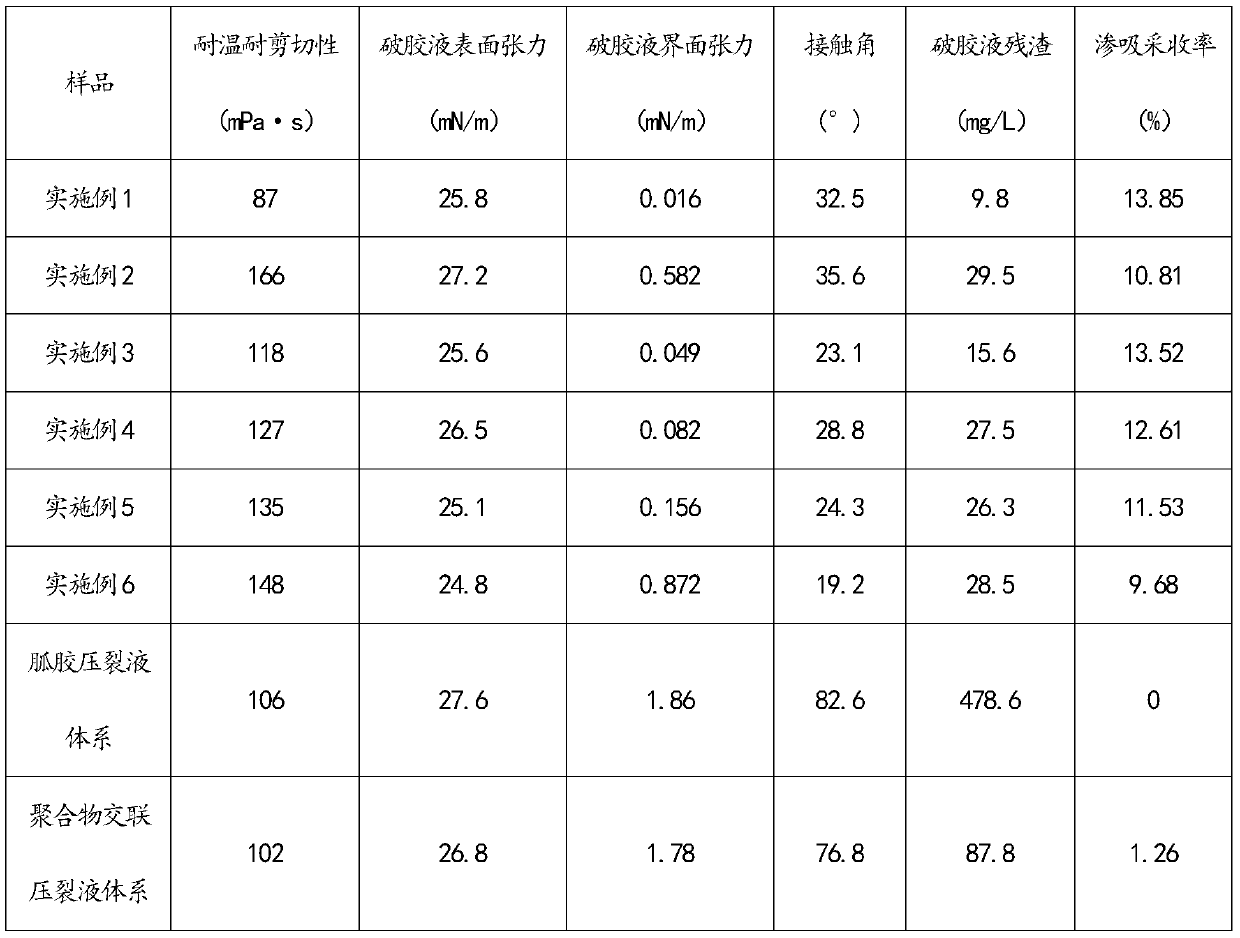

[0051]A supramolecular fracturing fluid system for imbibition oil recovery, based on its total weight as 100%, it includes: 0.4% supramolecular thickener (hydrophobic association polymer, CFZ-4, Sichuan Guangya Polymer Chemical Co., Ltd. company), 0.2% double-effect agent (betaine zwitterionic surfactant, CY-4, Shanghai Jianhong Industrial Co., Ltd.), 0.85% clay stabilizer (quaternary ammonium salt organic clay stabilizer class, GY- 1, Sichuan Guangya Polymer Chemical Co., Ltd.), 0.15% gel breaker (ammonium persulfate, PJ-1, Chengdu Kelong Chemical Reagent Factory) and the rest of the water.

[0052] Preparation method: Dissolve supramolecular fracturing fluid thickener CFZ-4 in water for 5-10 minutes, add clay stabilizer GY-1 and dual-effect agent CY-4 in proportion, stir for 5-10 minutes, then add gel breaker PJ -1 to obtain the supramolecular fracturing fluid system for imbibition recovery of the present invention.

Embodiment 1

[0068] A supramolecular fracturing fluid system for imbibition oil recovery, based on its total weight as 100%, it includes: 0.2% supramolecular thickener (hydrophobic association polymer, CFZ-1, Sichuan Guangya Polymer Chemical Co., Ltd. company), 0.05% double-effect agent (fluorocarbon surfactant, CY-1, Shanghai Jianhong Industrial Co., Ltd.), 0.05% clay stabilizer (quaternary ammonium salt organic clay stabilizer, GY-1, Sichuan Guangya Polymer Chemical Co., Ltd.), 0.05% high-efficiency gel breaker (ammonium persulfate, PJ-1, Chengdu Kelong Chemical Reagent Factory) and the rest of the water.

[0069] Preparation method: Dissolve supramolecular fracturing fluid thickener CFZ-1 in water for 5-10 minutes, add clay stabilizer GY-1 and dual-effect agent CY-1 in proportion, stir for 5-10 minutes, then add gel breaker PJ -1 to obtain the supramolecular fracturing fluid system for imbibition recovery of the present invention.

Embodiment 2

[0071] A supramolecular fracturing fluid system for imbibition oil recovery, based on its total weight as 100%, it includes: 0.7% supramolecular thickener (hydrophobic association polymer, CFZ-2, Sichuan Guangya Polymer Chemical Co., Ltd. company), 0.6% double-effect agent (sulfonate anionic surfactant, CY-2, Evonik Specialty Chemicals (Shanghai) Co., Ltd.), 2% clay stabilizer (potassium chloride, KCl, Chengdu Kelon Chemical Reagent Factory), 0.4% gel breaker (capsule gel breaker, PJ-2, Shaanxi Senrui Petroleum Technology Development Co., Ltd.) and the rest of the water.

[0072] Preparation method: Dissolve supramolecular fracturing fluid thickener CFZ-2 in water for 5-10 minutes, then add clay stabilizer KCl and dual-effect agent CY-2 in proportion, stir for 5-10 minutes, then add capsule breaker PJ- 2. Obtain the supramolecular fracturing fluid system for imbibition oil recovery described in the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com