Compound for metal organic framework encapsulating corrosion inhibitor and preparation method and application thereof

A technology of metal-organic framework and corrosion inhibitor, which is applied in the field of metal-organic framework-encapsulated corrosion inhibitor compound and its preparation, can solve the problems of lack of water stability and acid-sensitive dissociation, and achieve sensitive anti-corrosion performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

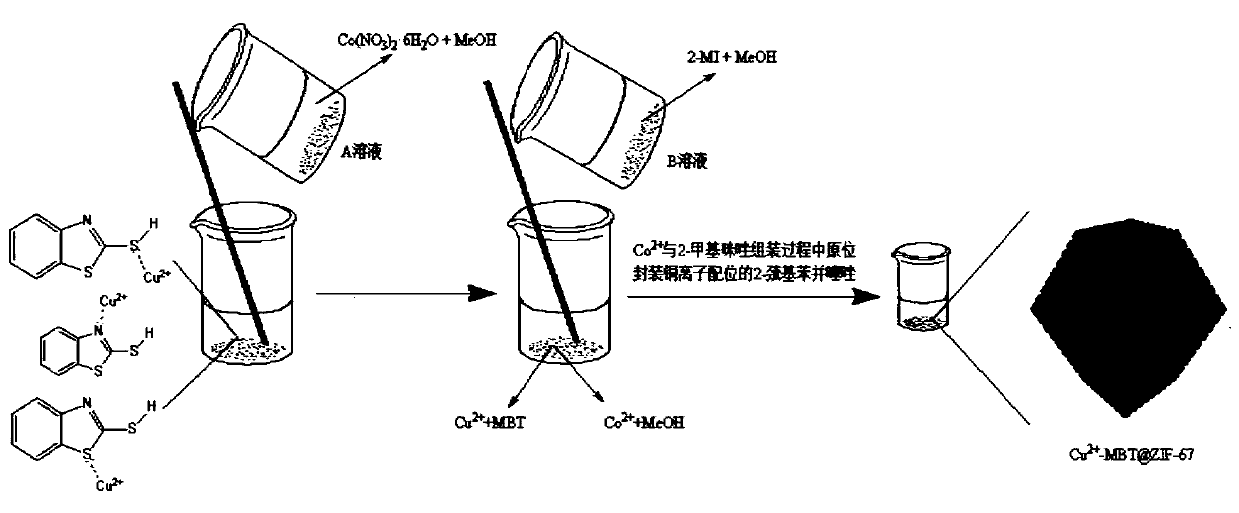

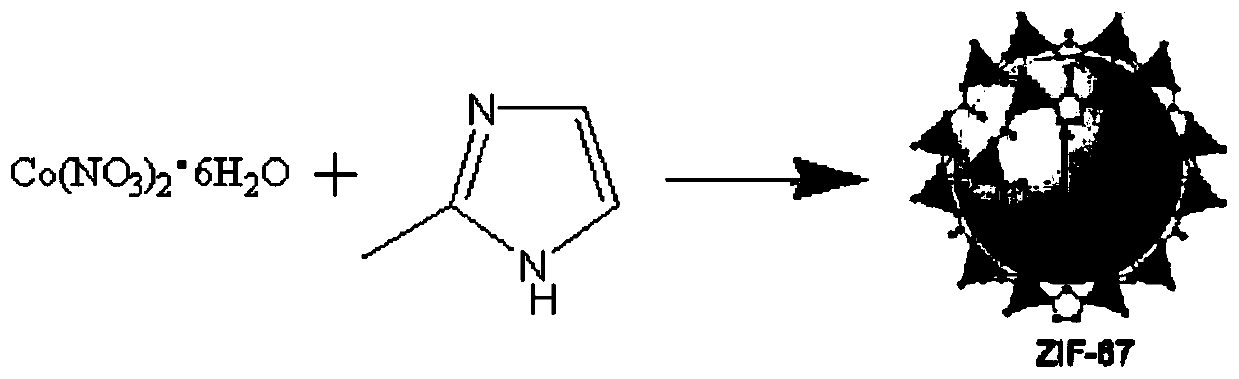

[0047] Preparation of ZIF-67 Encapsulated Copper Ion Modified Thiazole Corrosion Inhibitor Complex

[0048] The first step: preparation of copper ion-modified 2-mercaptobenzothiazole precursor:

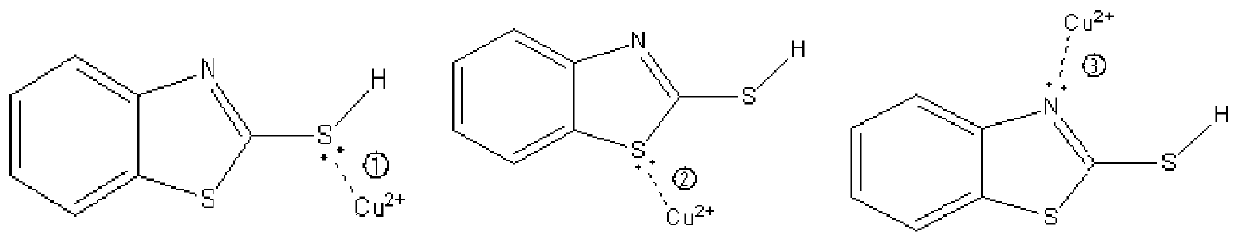

[0049] Firstly, 3.95g of Tris base was dissolved in 13mL of deionized water, then the volume was adjusted to 25mL with deionized water, and then the pH was adjusted to 8.8 with ammonium chloride to obtain a buffer solution. Add 69 mg (0.41 mmol) 2-mercaptobenzothiazole and 50 mg (0.21 mmol) copper nitrate trihydrate (2-mercaptobenzothiazole to copper nitrate trihydrate molar ratio is about 2:1) at room temperature into the above buffer solution and stirred at room temperature for 30 min to obtain a copper ion-modified thiazole-containing corrosion inhibitor precursor with a yield of 83%.

[0050] The above-mentioned 2-mercaptobenzothiazole and copper nitrate trihydrate have a coordination reaction between copper ions and 2-mercaptobenzothiazole active groups at a molar ratio of 2 to ...

Embodiment 2

[0057] Preparation of ZIF-67 Encapsulated Copper Ion Modified Thiazole Corrosion Inhibitor Complex

[0058] The first step: preparation of copper ion-modified 2-mercaptobenzothiazole precursor:

[0059] Firstly, 3.95g of Tris base was dissolved in 13mL of deionized water, then the volume was adjusted to 25mL with deionized water, and then the pH was adjusted to 8.8 with ammonium chloride to obtain a buffer solution. Add 104mg (0.62mmol) 2-mercaptobenzothiazole and 50mg (0.21mmol) copper nitrate trihydrate (the molar ratio of 2-mercaptobenzothiazole to copper nitrate trihydrate is about 3:1) at room temperature into the above buffer solution and stirred at room temperature for 30 min to obtain a copper ion-modified thiazole-containing corrosion inhibitor precursor with a yield of 88%.

[0060] The above-mentioned 2-mercaptobenzothiazole and copper nitrate trihydrate have a coordination reaction between copper ions and 2-mercaptobenzothiazole active groups at a molar ratio of 2...

Embodiment 3

[0067] Preparation of ZIF-67 Encapsulated Copper Ion Modified Thiazole Corrosion Inhibitor Complex

[0068] The first step: preparation of copper ion-modified 2-mercaptobenzothiazole precursor:

[0069] Firstly, 3.95g of Tris base was dissolved in 13mL of deionized water, then the volume was adjusted to 25mL with deionized water, and then the pH was adjusted to 8.8 with ammonium chloride to obtain a buffer solution. Add 138mg (0.83mol) 2-mercaptobenzothiazole and 50mg (0.21mol) copper nitrate trihydrate (the molar ratio of 2-mercaptobenzothiazole to copper nitrate trihydrate is about 4:1) at room temperature into the above buffer solution and stirred at room temperature for 30 min to obtain a copper ion-modified thiazole-containing corrosion inhibitor precursor with a yield of 85%.

[0070] The above-mentioned 2-mercaptobenzothiazole and copper nitrate trihydrate have a coordination reaction between copper ions and 2-mercaptobenzothiazole active groups at a molar ratio of 2 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com