Hole transport material and preparation method thereof, and quantum dot light-emitting diode

A hole transport material and quantum dot luminescence technology, applied in the field of quantum dots, can solve problems such as low transport performance and poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

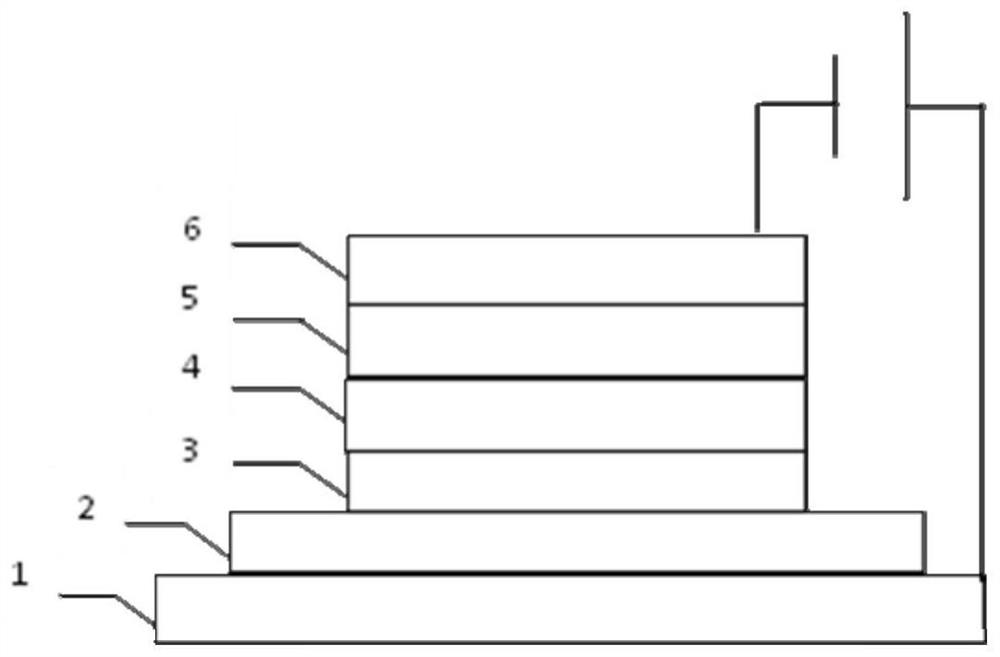

Method used

Image

Examples

preparation example Construction

[0023] On the other hand, an embodiment of the present invention also provides a method for preparing a hole transport material, comprising the following steps:

[0024] S01: Provide zinc sulfide nanoparticles and nano-scale carbon nitride;

[0025] S02: Dissolving the zinc sulfide nanoparticles and nanoscale carbon nitride in a solvent to obtain a precursor solution;

[0026] S03: Deposit the precursor solution on the substrate, and perform annealing treatment to obtain a hole transport material.

[0027] The preparation method of the hole transport material provided by the embodiment of the present invention is simple and feasible, suitable for large-scale and large-scale preparation, and finally obtains a hole transport material with a suitable band gap and strong hole transport ability, which can be used to prepare QLED devices. The hole transport layer can significantly improve the luminous efficiency, luminous stability and service life of the device.

[0028] Further,...

Embodiment 1

[0048] Using zinc sulfate, sodium sulfide, and carbon nitride nanospheres to prepare hole transport materials, the specific steps are as follows:

[0049] 1) Add an appropriate amount of zinc sulfate to ethanol to form a 1.0mol / L zinc sulfate solution, and continue heating and stirring at 50 degrees Celsius; then add an appropriate amount of sodium sulfide to ethanol to form a 1.0mol / L sodium sulfide solution. Stir continuously under heating;

[0050] 2) Inject the sodium sulfide solution into the zinc sulfate solution so that the molar ratio Zn 2+ :S 2- =1:1, continue to stir at 50 degrees Celsius for 1 hour;

[0051] 3) After cooling the mixed solution to room temperature and centrifuging, remove the supernatant, redisperse the lower solid with ethanol and wash it several times, then dissolve it in ethanol to form a zinc sulfide ethanol solution;

[0052] 4) Add carbon nitride nanospheres to the zinc sulfide ethanol solution to make the molar ratio Zn:C 3 N 4 =1:0.02, a...

Embodiment 2

[0055] Using zinc chloride, sulfur powder, and carbon nitride nanorods to prepare hole transport materials, the specific steps are as follows:

[0056] 1) Add an appropriate amount of zinc chloride to acetone to form a 1.0mol / L zinc chloride solution, and continue heating and stirring at 50 degrees Celsius; add an appropriate amount of sulfur powder to acetone to form an acetone solution of 1.0mol / L sulfur. Continue heating and stirring at 50 degrees Celsius;

[0057] 2) Inject the acetone solution of sulfur into the zinc chloride solution so that the molar ratio Zn 2+ :S 2- =1:1, continue to stir at 50 degrees Celsius for 1 hour;

[0058] 3) After cooling the mixed solution to room temperature and centrifuging, remove the supernatant, redisperse the lower solid with acetone and wash it several times, then dissolve it in acetone to form a zinc sulfide acetone solution;

[0059] 4) Add carbon nitride nanorod powder to the zinc sulfide acetone solution to make the molar ratio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com