Nanometer material and preparation method thereof, and quantum dot light emitting diode

A technology of quantum dot light-emitting and nanomaterials, which is applied in the field of flat panel display to achieve the effects of simple method, high stability and improved electron transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

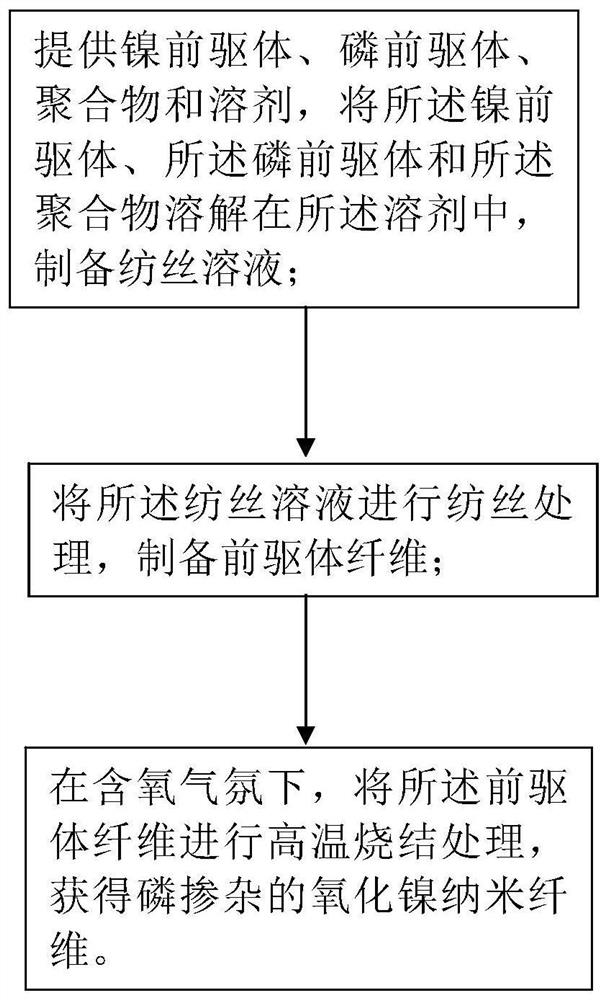

[0022] A kind of preparation method of above-mentioned nano material, please refer to figure 1 , including the following steps:

[0023] S01, providing a nickel precursor, a phosphorus precursor, a polymer and a solvent, dissolving the nickel precursor, the phosphorus precursor and the polymer in the solvent to prepare a spinning solution;

[0024] S02. Spinning the spinning solution to prepare precursor fibers;

[0025] S03. Sintering the precursor fiber at a high temperature in an oxygen-containing atmosphere to obtain phosphorus-doped nickel oxide nanofibers.

[0026] The preparation method of the above-mentioned nanomaterials provided in the embodiments of the present invention combines spinning processing and high-temperature sintering techniques to synthesize a nickel oxide nanofiber, which has the characteristics of elongated fibers and a staggered morphology, and during the synthesis process Phosphorus atoms replace part of the oxygen sites of nickel oxide, and simul...

Embodiment 1

[0056] A kind of nanometer material is prepared in this embodiment, and the specific technological process is as follows:

[0057] S11. Dissolving nickel nitrate in ethanol to prepare a nickel precursor solution with a concentration of 200mg / mL; then, adding phosphorus powder to the nickel precursor solution so that the molar ratio of nickel to phosphorus is 1:0.005; after that, Add PP accounting for about 20% of the ethanol volume into the mixed solution, and stir until the PP is evenly dispersed in the mixed solution to prepare a spinning solution;

[0058] S12. Spinning the spinning solution by air-spinning method to obtain cotton-like flocs and obtain precursor fibers;

[0059] S13, drying the above-mentioned precursor fiber, and then, under an oxygen atmosphere, sintering the precursor fiber at 400° C. for 2 hours at a high temperature, and then grinding the sintered product until the fiber length is 10-100 μm after cooling down to room temperature, With a diameter of 5-...

Embodiment 2

[0062] A kind of nanometer material is prepared in this embodiment, and the specific technological process is as follows:

[0063] S21. Dissolving nickel sulfate in ethanol to prepare a nickel precursor solution with a concentration of 200mg / mL; then, adding phosphorus powder to the nickel precursor solution so that the molar ratio of nickel to phosphorus is 1:0.005; after that, Add PVC accounting for about 20% of the volume of ethanol to the mixed solution, and stir until the PVC is evenly dispersed in the mixed solution to prepare a spinning solution;

[0064] S22. Spinning the spinning solution by using an air spinning method to obtain cotton-like flocs and obtain precursor fibers;

[0065] S23. Dry the above-mentioned precursor fibers, and then, under an oxygen atmosphere, sinter the precursor fibers at 400° C. for 2 hours at a high temperature, and then grind the sintered products until the fiber length is 10-100 μm after cooling down to room temperature. With a diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com