Composite material and its preparation method and quantum dot light-emitting diode

A composite material, nitrogen atom technology, applied in the field of materials, can solve problems such as unsatisfactory hole transport effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

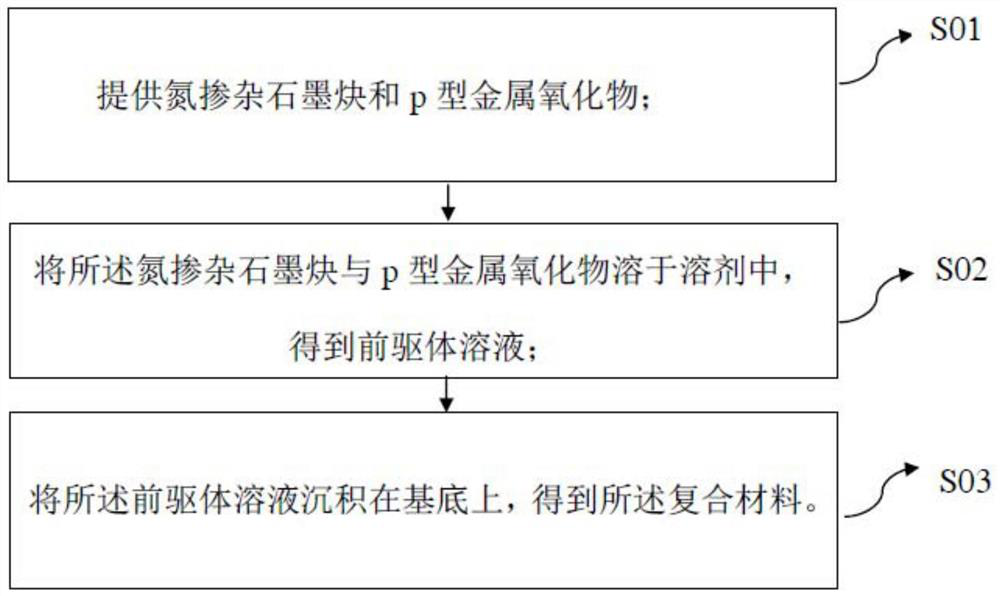

[0026] On the other hand, the embodiment of the present invention also provides a method for preparing a composite material, such as figure 1 shown, including the following steps:

[0027] S01: Provide nitrogen-doped graphyne and p-type metal oxides;

[0028] S02: dissolving the nitrogen-doped graphyne and p-type metal oxide in a solvent to obtain a precursor solution;

[0029] S03: Depositing the precursor solution on a substrate to obtain the composite material.

[0030] The preparation method of the composite material provided by the embodiment of the present invention is obtained by directly dissolving nitrogen-doped graphyne and p-type metal oxide in a solvent, and then depositing it on a substrate and annealing it. The preparation method has simple process and low cost, and the finally obtained composite material can significantly improve the charge transport performance, and the use of the compound material in the hole transport material can improve the hole transport...

Embodiment 1

[0046] The following uses α-graphyne (α-GY) nano-microsphere powder, n-butanol solvent, and nickel oxide nanoparticles as examples for a detailed introduction:

[0047] 1) Evenly spread the α-graphyne powder on a watch glass, place it in an argon atmosphere and heat it to a certain temperature of 250 degrees Celsius;

[0048] 2) 5% ammonia gas (95% argon balance) is slowly passed into the graphyne powder, and the heating and ventilation are continued for 30 minutes to obtain a nitrogen-doped graphyne material;

[0049] 3) Disperse nitrogen-doped graphyne and nickel oxide particles in n-butanol solvent and stir for a certain period of time to obtain a mixed colloidal solution of hole transport materials;

[0050] 4) Depositing the mixed solution of the nitrogen-doped graphyne hybridized nickel oxide hole transport material on the anode substrate to prepare a hole transport material layer.

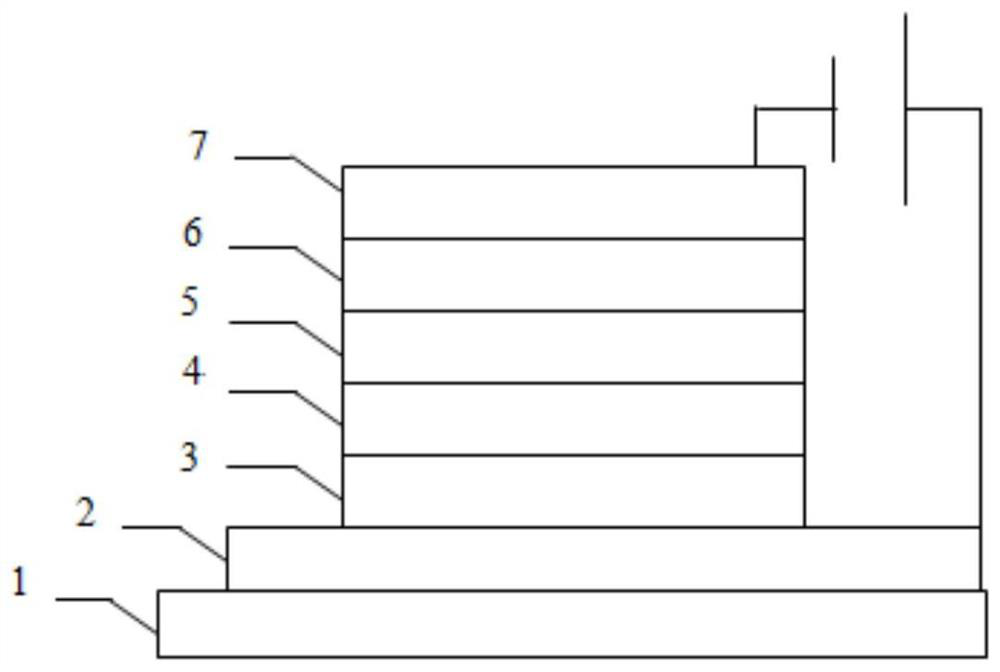

[0051] 5) sequentially depositing a quantum dot light-emitting layer, an electron trans...

Embodiment 2

[0053] The following uses δ-graphyne (δ-GY) nano-microsphere powder, ethanol solvent, and molybdenum oxide nanoparticles as examples for a detailed introduction:

[0054] 1) Evenly spread the δ-graphyne powder on a watch glass, place it in an argon atmosphere and heat it to a certain temperature of 250 degrees Celsius;

[0055] 2) 5% ammonia gas (95% argon balance) is slowly passed into the graphyne powder, and the heating and ventilation are continued for 30 minutes to obtain a nitrogen-doped graphyne material;

[0056] 3) Disperse nitrogen-doped graphyne and molybdenum oxide particles in an ethanol solvent and stir for a certain period of time to obtain a mixed colloidal solution of hole transport materials;

[0057] 4) Depositing the mixed solution of the nitrogen-doped graphyne hybridized molybdenum oxide hole transport material on the anode substrate to prepare a hole transport material layer.

[0058] 5) sequentially depositing a quantum dot light-emitting layer, an ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hole mobility | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com