Semicoke-based activated carbon adsorption material as well as preparation method and application thereof

A technology based on activity and carbon adsorption, applied in separation methods, chemical instruments and methods, other chemical processes, etc., can solve the problems of difficult hole expansion, limited application of semi-coke-based activated carbon materials, imperfect processes, etc., and achieve economical Significant benefits, less heat of adsorption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

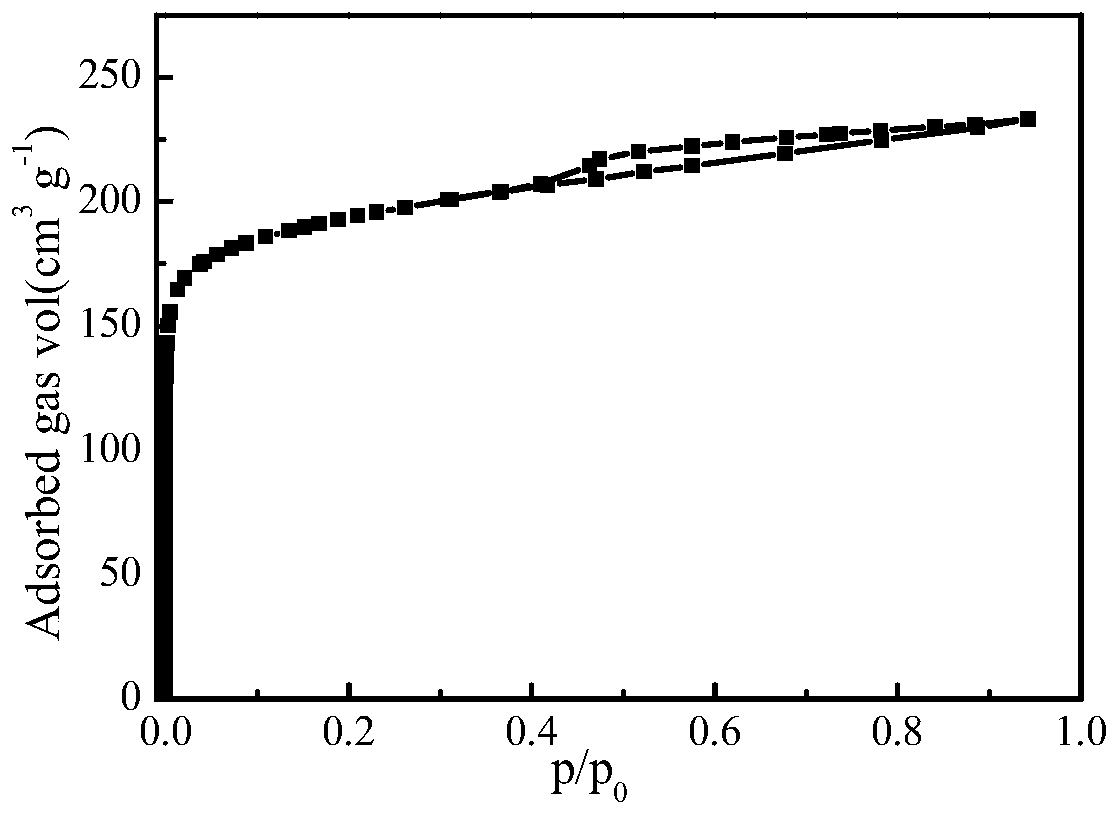

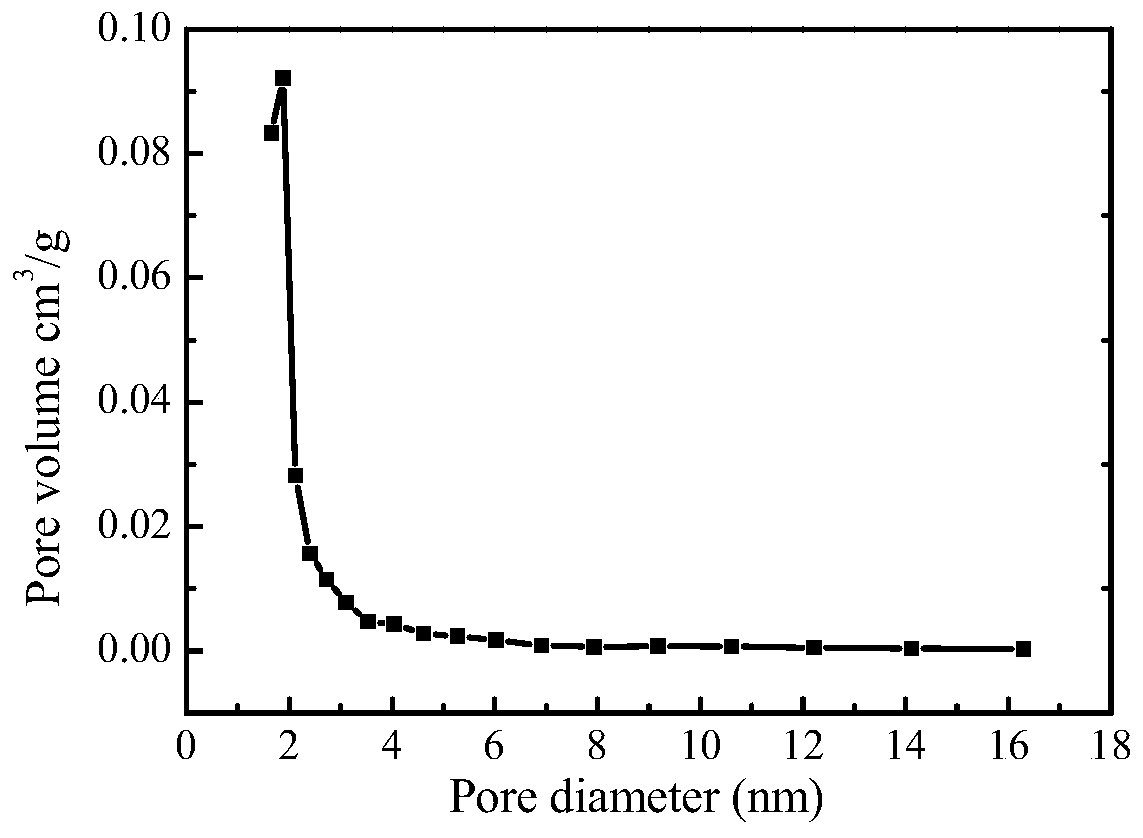

[0023] The preparation method of the semi-coke-based activated carbon adsorption material according to the second aspect of the present invention is used to prepare the semi-coke-based activated carbon adsorption material of the first aspect of the present invention, including: step one, providing semi-coke powder; The coke powder is added to the potassium hydroxide solution and immersed at room temperature to obtain the sample. The sample is dried and sealed to obtain the immersed semi-coke; step three, the immersed semi-coke is heated, and carbon dioxide gas is used as the activator to activate The activated semi-coke-based activated carbon adsorption material is dried in a vacuum and sealed for storage.

[0024] In the preparation method of the semi-coke-based activated carbon adsorption material according to the second aspect of the present invention, in step 1, the particle size of the semi-coke powder is 60 mesh.

[0025] In the preparation method of the semi-coke-based activ...

Embodiment 1

[0037] Step 1: Take the semi-coke raw material and grind it in a ball mill for 8 hours to obtain 60 mesh semi-coke powder.

[0038] Step 2: Add 20 g of ground 60 mesh semi-coke powder to 20 mL of 1 mmol / L KOH solution and soak at room temperature for 6 hours, and then dry the obtained sample at 60° C. and store it in a sealed container.

[0039] Step 3. Take 10g of the semi-coke material after immersion, control the activation temperature to 700°C, the heating time 40min, the activation time 120min, and the activator flow rate 60mL / min. After activation, vacuum dry the activated carbon at 120°C and keep it sealed. Activator is CO 2 gas.

Embodiment 2-27

[0041] The semi-coke-based activated carbon adsorption material was prepared using the method of Example 1, wherein the parameter settings during the preparation process are listed in Table 1.

[0042] In addition, the drying temperature in step two is 60°C, the heating time in step three is 40 minutes, and the vacuum drying temperature is 120°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com