Method for preparing platinum-graphene-molybdenum sulfide composite material by low-temperature plasma

A technology of low-temperature plasma and low-temperature plasma, which is applied in the field of preparing platinum-graphene-molybdenum sulfide composite materials by plasma, can solve the problem that the synthesis process cannot control nitrogen doping, etc., and achieve easy control of the reaction process, avoiding the synthesis process, and the conditions less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present invention proposes a new preparation method of platinum / molybdenum sulfide-graphene composite material, which can prepare molybdenum sulfide material with 3D dendritic structure, and can effectively compound with carbon nitride substrate to form a specific heterogeneous The junction structure has broad application prospects in the field of electrocatalytic hydrogen production.

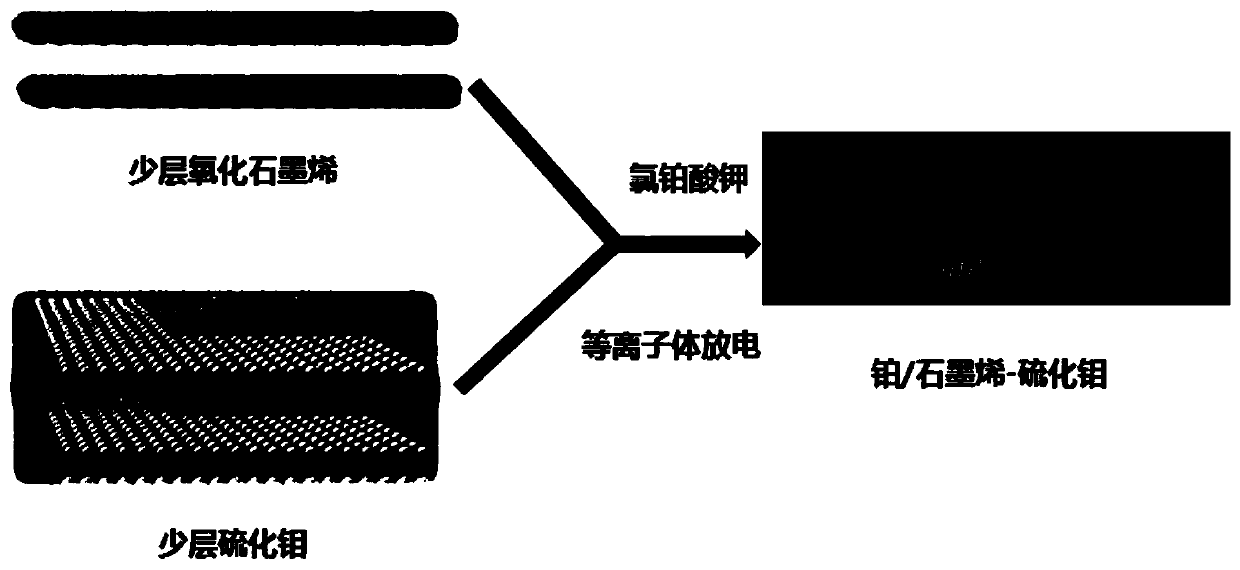

[0028] Such as figure 1 As shown, the method included in the present invention is: mix 1mL of 24.09mmol / L potassium chloroplatinate, 5mL of molybdenum sulfide of the same concentration and 5mL of graphene oxide solution to obtain a mixed solution; carry out ultrasonication on the mixed solution for 20-40min, 30min, to obtain Dispersion liquid: Centrifuge the dispersion liquid at a speed of 5000-12000rbm for 5-30min. Freeze-dry the isolated precipitated compound at minus 20°C to minus 50°C; then, the dried powder is subjected to low-temperature plasma discharge in a hydrogen atmosphe...

Embodiment 2

[0030] The methods included in the present invention include: mixing 1mL of 24.09mmol / L potassium chloroplatinate, 5mL of 2mg / ml molybdenum sulfide and 5mL of 2mg / ml graphene oxide solution to obtain a mixed solution; ultrasonicating the mixed solution for 30min to obtain a dispersion ; Carry out centrifugation on the dispersion liquid, the speed of centrifugation is 5000-12000rbm, and the time is 5-30min. Freeze-dry the isolated precipitated compound at minus 20°C to minus 50°C; then, the dried powder is subjected to low-temperature plasma discharge in a hydrogen atmosphere, the temperature of low-temperature plasma discharge is 30-50°C, and the pressure is 70Pa. The discharge power is 100W, the discharge time is 40min, and the hydrogen flow rate is 25sccm. The mass ratio of graphene and molybdenum sulfide is 1:1.

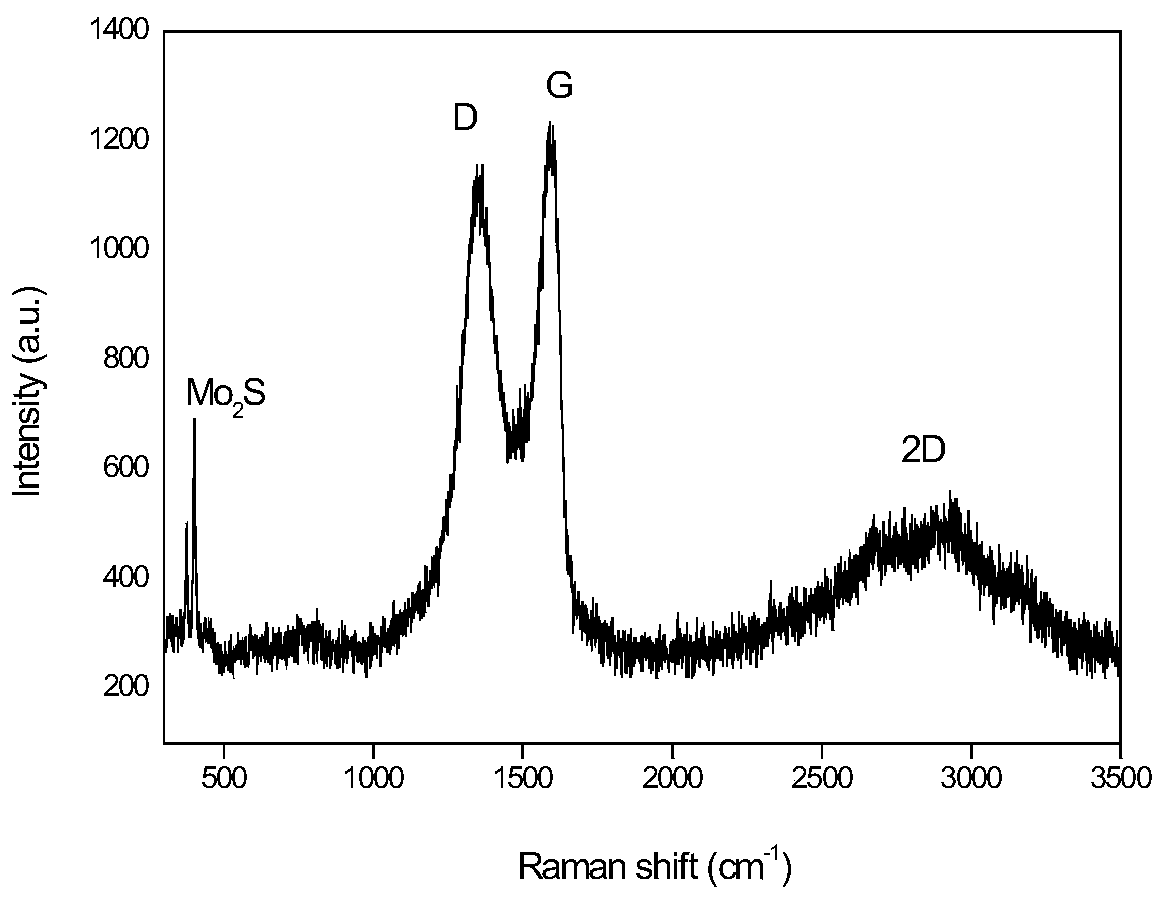

[0031] In the present embodiment, it has also been verified that the product obtained by the present invention has a good effect through various data:

[0032] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com