Wax dispersant for toner and toner

A technology of wax dispersant and toner, applied in the field of wax dispersant for toner, can solve the problems of deterioration of toner charging performance, deterioration of toner fluidity, etc. blocky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

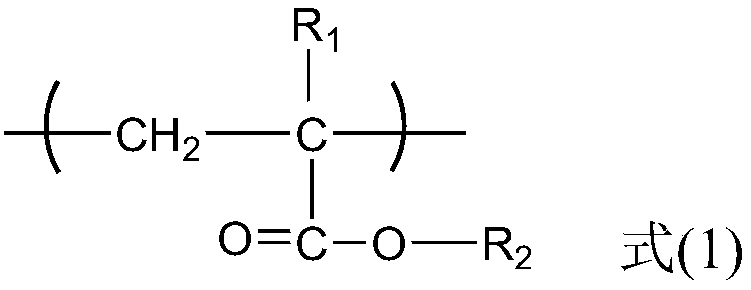

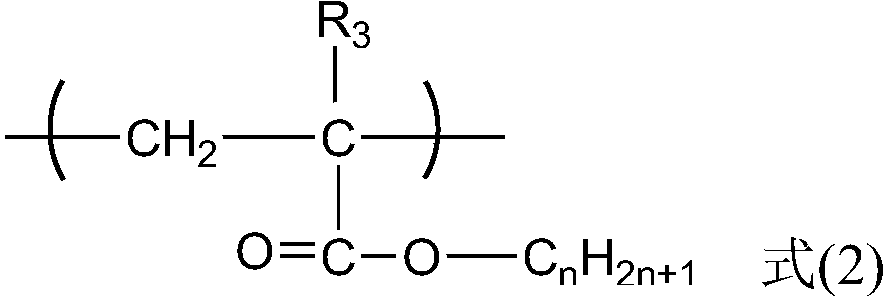

Method used

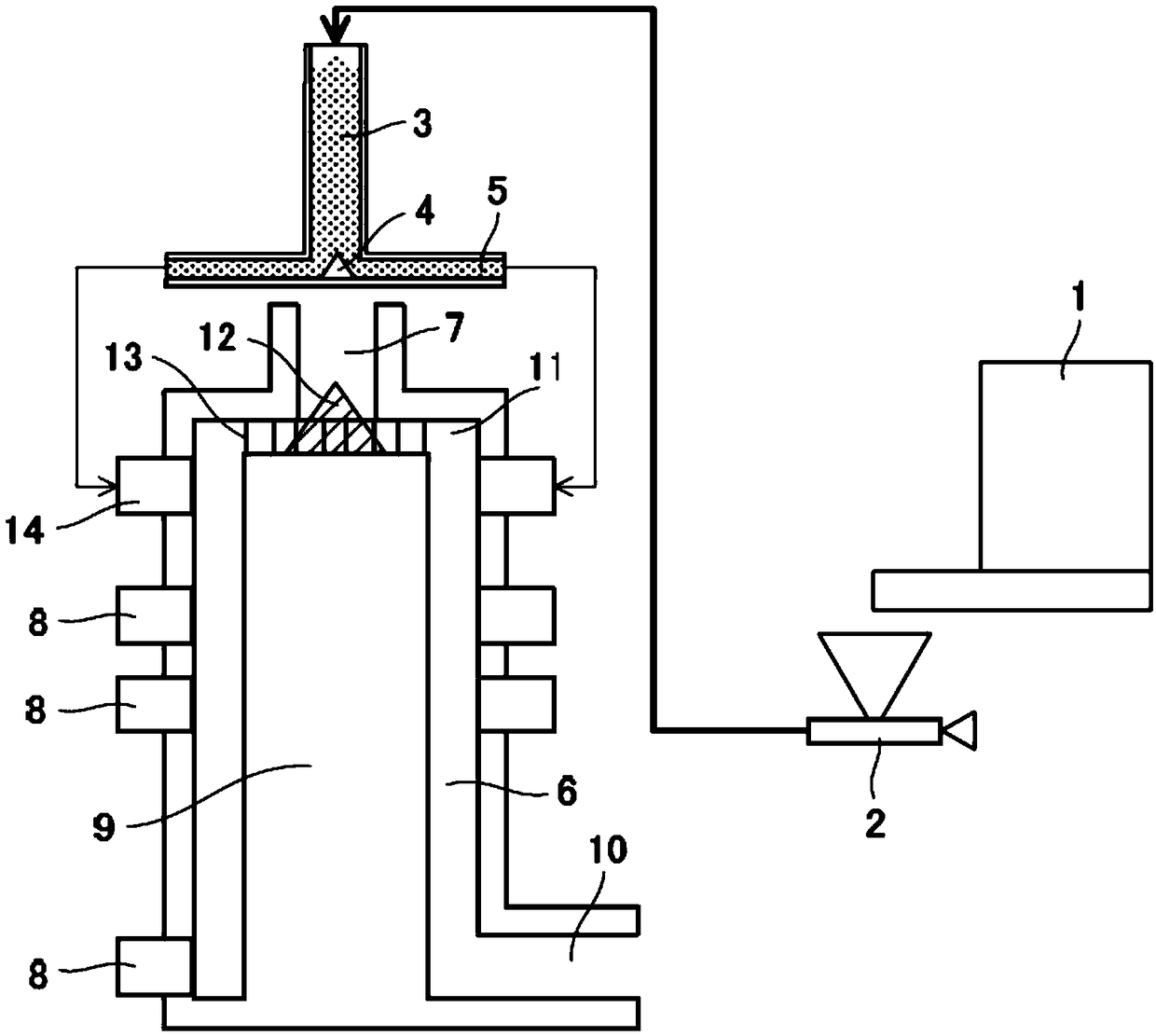

Image

Examples

preparation example Construction

[0253] (1) Preparation of reagents

[0254] A phenolphthalein solution was obtained by dissolving 1.0 g of phenolphthalein in 90 mL of ethanol (95 vol%) and adding deionized water to 100 mL.

[0255] A total of 7 g of reagent grade sodium chloride was dissolved in 5 mL of deionized water and 1 L was obtained by adding ethanol (95 vol%). The solution was put into an alkali-resistant container, and allowed to stand there for 3 days to prevent contact with carbon dioxide, etc., and then filtered to obtain a potassium hydroxide solution. Store the resulting potassium hydroxide solution in an alkali-resistant container. Add a total of 25mL of 0.1mol / L hydrochloric acid into the Erlenmeyer flask, add a few drops of phenolphthalein solution, titrate with potassium hydroxide solution, and obtain the factor of potassium hydroxide solution from the amount of potassium hydroxide solution required for neutralization. 0.1 mol / L hydrochloric acid was prepared for use according to JIS K 80...

Embodiment

[0265] Hereinafter, the present invention will be described in more detail with reference to Preparation Examples and Embodiments, but the present invention is not limited thereto. All parts and percentages in the following formulations are by mass unless otherwise stated.

[0266]

[0267] A total of 300.0 parts of xylene and 10.0 parts of polypropylene (melting point 90° C.) were put into an autoclave reaction vessel equipped with a thermometer and a stirrer, and the polypropylene was completely dissolved. After nitrogen replacement, at 180°C, after 3 hours, a mixed solution of 68.0 parts of styrene, 5.0 parts of methacrylic acid, 5.0 parts of cyclohexyl methacrylate, 12.0 parts of butyl acrylate and 250.0 parts of xylene was added dropwise to to aggregate. Then, the reaction system was kept at this temperature for 30 minutes, and the solvent was removed to obtain wax dispersant A1. The composition, weight average molecular weight and acid value of the obtained wax dispe...

preparation example

[0298]

[0299] - Polyoxypropylene(2.8)-2,2-bis(4-hydroxyphenyl)propane: 76.6 parts (0.17 mol; 100.0 mol% based on the total moles of polyol)

[0300] - Terephthalic acid: 17.4 parts (0.10 mol; 72.0 mol% based on the total moles of polycarboxylic acids)

[0301] - Adipic acid: 6.0 parts (0.04 mol; 28.0 mol% based on the total moles of polycarboxylic acids)

[0302] - Tetrabutyl titanate (esterification catalyst): 0.5 parts

[0303] The above materials were weighed in a reaction vessel equipped with a cooling tube, a stirrer, a nitrogen gas introduction tube and a thermocouple.

[0304] After the atmosphere inside the reaction vessel was replaced with nitrogen, the temperature was gradually raised under stirring, and the reaction was performed at a temperature of 200° C. for 4 h under stirring.

[0305] Then, the pressure of the reaction vessel was reduced to 8.3 kPa and maintained for 1 h. Then, cooling to 180° C. was performed, and the pressure was returned to atmospheri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com