System and method for preparing CNG from medium and low temperature dry distillation raw coke oven gas through sulfur-resistant uniform-temperature methanation

A technology that is resistant to sulfur methanation and waste gas. It is applied in special forms of dry distillation, chemical modification of combustible gas, and purification/reconstruction of combustible gas. The effect of shortened process flow and high CH4 selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

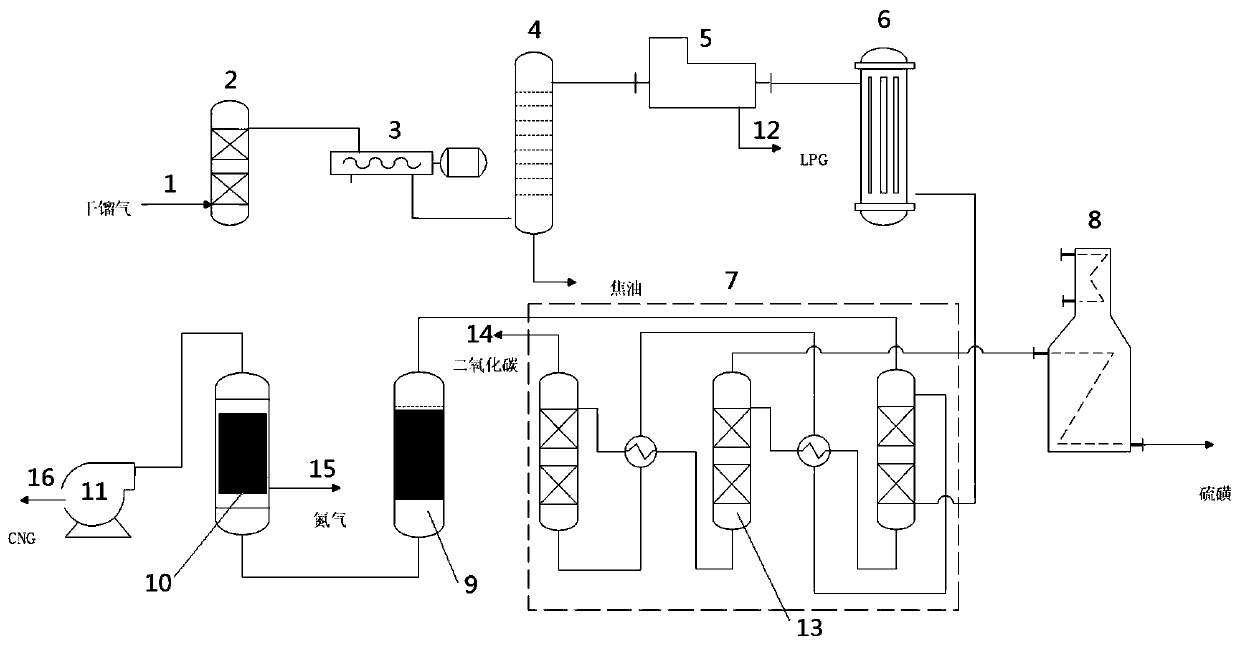

[0034] figure 1 It is a system for producing CNG from medium and low temperature retort raw coal gas through sulfur-resistant and uniform temperature methanation of the present invention, including a deammonization and dust removal device 2, the inlet of the deammonization and dust removal device 2 is connected with a medium and low temperature retort raw gas inlet pipe 1, and the outlet is connected with a first-stage Compression device 3, primary compression device 3 is connected with tar recovery device 4, and tar recovery device 4 can adopt rectifying tower or temperature swing adsorption device; Tar recovery device 4 is connected with secondary compression device 5, can also be in tar recovery device 4 and A deoxygenation device is arranged between the two-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com