Lithium ion battery diaphragm

A lithium-ion battery and separator technology, which is applied to the high-performance lithium-ion battery separator and its application and preparation fields, can solve the problems of blockage of membrane pores, insufficient stability of the separator, insufficient high temperature resistance, etc., and achieves strong and stable high temperature resistance. The effect of high stability and high ion mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Preparation of diaphragm

[0065] S1. Prepare a polypropylene base material with a thickness of 20 μm, and use a brush to roughen the base material;

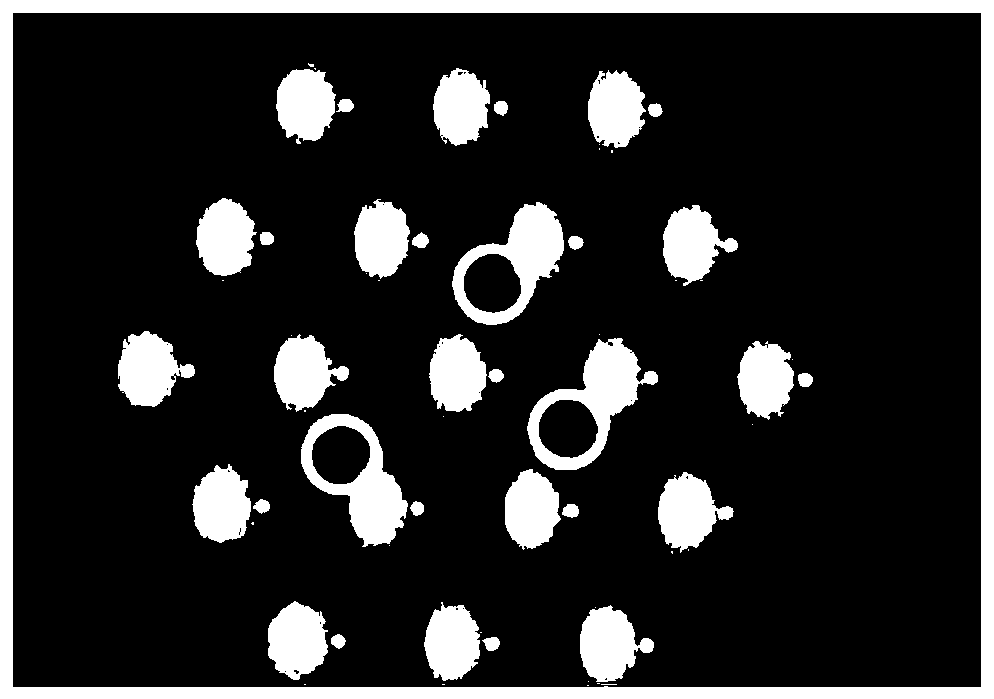

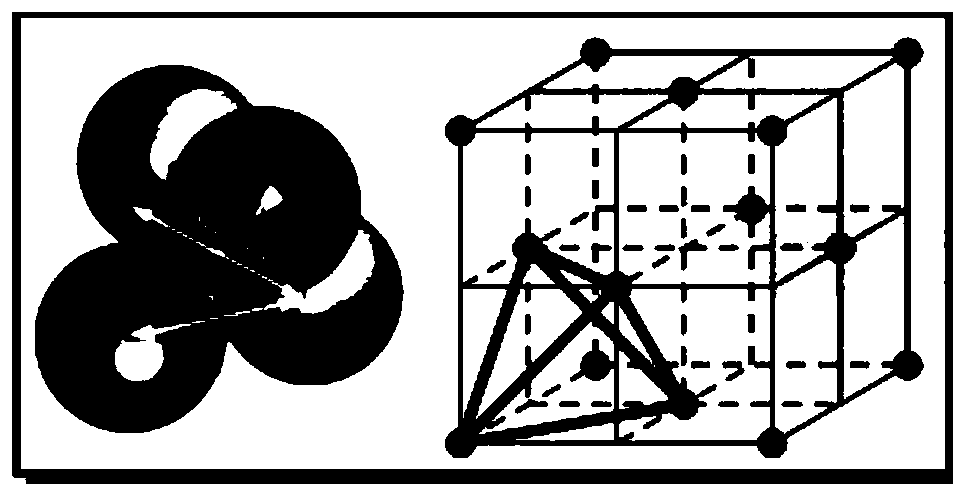

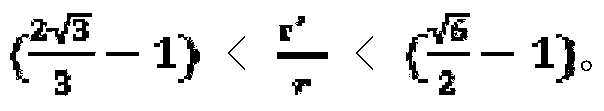

[0066] S2, the first particle boehmite used for preparing the slurry, the first particle boehmite r=50nm and the second particle egg shell powder r'=10nm; 98 parts of boehmite are added to 0.2wt% polyvinyl alcohol (alcohol degree of hydrolysis: 99mol%, viscosity: 29mPa.s) dispersed in water, milled for 5 minutes to configure the first particle slurry for use; add 2 parts of egg shell powder to 0.8wt% polyvinyl alcohol (degree of alcoholysis: 99mol%, Viscosity: 29mPa.s) dispersed in water, ultrasonically dispersed for 5 minutes to prepare the second particle slurry for use;

[0067] S3, spraying the first particles on both sides of the substrate to form a first particle layer, and spraying the second particles in the gaps of the first particle layer to form a second particle layer;

[0068] S4, drying the base material a...

Embodiment 2

[0072] Preparation of diaphragm

[0073] S1. Prepare a polypropylene base material with a thickness of 40 μm, and use a brush to roughen the base material;

[0074] S2, modify the first particle boehmite, the first particle boehmite r=50nm and the second particle shell powder r'=10nm; 98 parts of boehmite are added to 0.2wt% polyvinyl alcohol (degree of alcoholysis: 99mol%, viscosity: 28mPa.s) dispersed in water, ball milled for 5min to configure the first particle slurry for use; add 0.8wt% polyvinyl alcohol (alcoholysis degree: 99mol%, viscosity: 29mPa. s) Disperse in water, disperse in water, and ultrasonically disperse for 5 minutes to prepare the second particle slurry for use;

[0075] S3, spraying the first particles on both sides of the substrate to form a first particle layer, and spraying the second particles in the gaps of the first particle layer to form a second particle layer;

[0076] S4, drying the base material and the first granular layer and the second gra...

Embodiment 3

[0080] Preparation of diaphragm

[0081] S1. Prepare a polypropylene base material with a thickness of 40 μm, and use a brush to roughen the base material;

[0082] S2, modify the first particle boehmite, the first particle boehmite r=50nm and the second particle polyethylene glycol particle r'=10nm; 98 parts of boehmite are added to 0.2wt% polyvinyl alcohol (alcohol degree of hydrolysis: 99mol%, viscosity: 28mPa.s) dispersed in water, milled for 5 minutes to configure the first particle slurry for use; add 2 parts of polyethylene glycol particles to 0.8wt% polyvinyl alcohol (degree of alcoholysis: 99mol %, viscosity: 29mPa.s) dispersed in water, dispersed in water, ultrasonically dispersed for 5 minutes to configure the second particle slurry for use;

[0083] S3, spraying the first particles on both sides of the substrate to form a first particle layer, and spraying the second particles in the gaps of the first particle layer to form a second particle layer;

[0084] S4, d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Degree of alcoholysis | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com